A method of manufacturing a pcb

A manufacturing method and sub-board technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit and other directions, can solve the problems of semi-cured P-chip not belonging to high-frequency and high-speed materials, restricting use, signal loss, etc., to improve the signal Transmission quality and speed, the effect of expanding the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

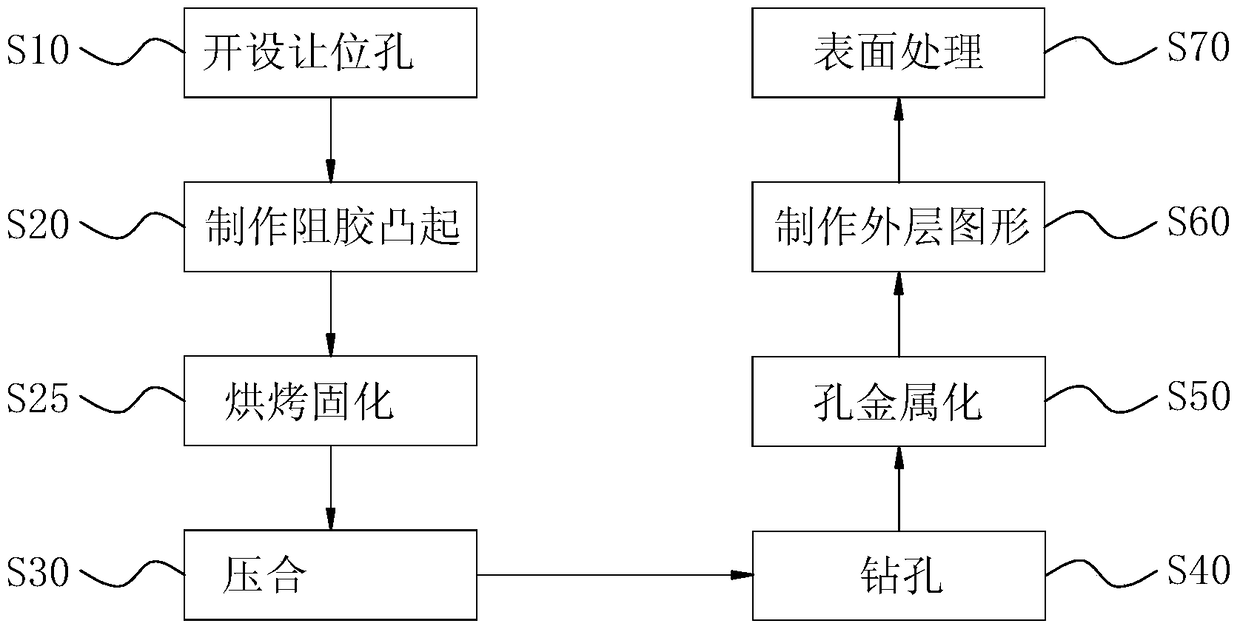

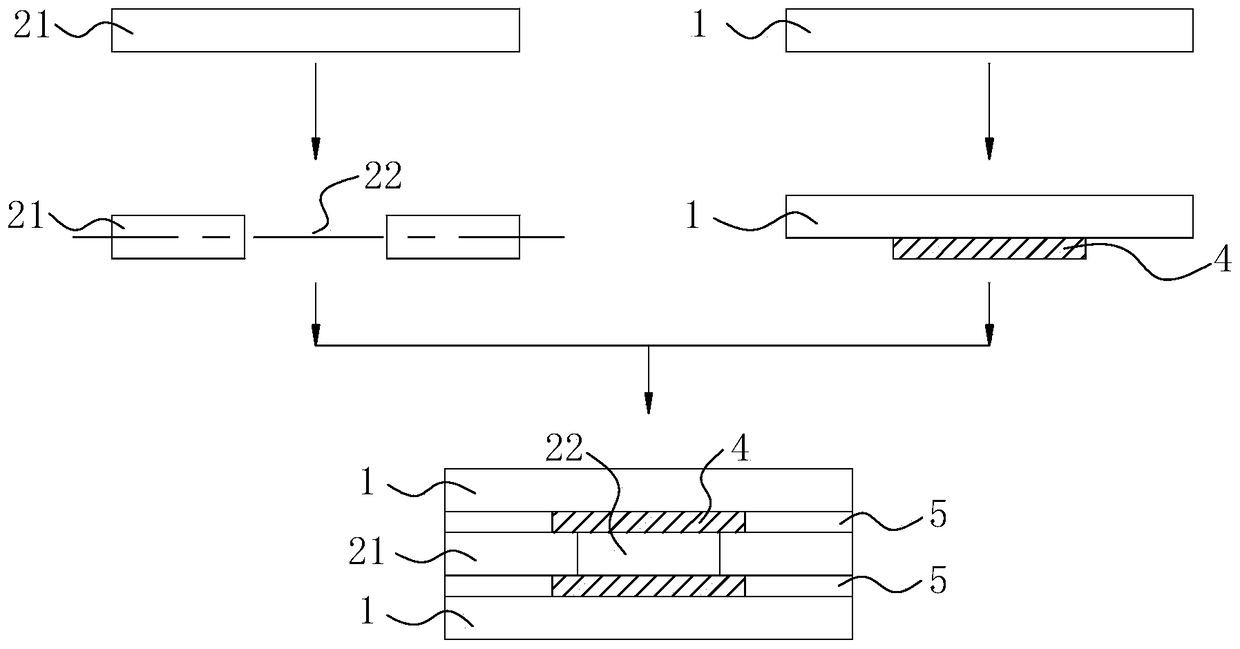

[0050] Such as figure 1 and figure 2 Shown, a kind of manufacturing method of PCB comprises the following steps:

[0051] S10. Open a relief hole 22 on the sub-board 2;

[0052] S20. Provide a non-perforated core board, and make glue-resistant protrusions 4 on the end surface of the non-perforated core board adjacent to the sub-board 2 close to the sub-board 2;

[0053] S25. Baking the non-perforated core board with the glue-resistant protrusions 4, so that the glue-resistant protrusions 4 are cured on the non-perforated core board;

[0054] S30, providing a prepreg 5, pressing the non-perforated core board, the prepreg 5 and the sub-board 2, so that the glue-resisting protrusion 4 covers the end of the relief hole 22, forming a laminated board with a closed cavity;

[0055] S40, drilling the plywood, and performing post-drilling treatment;

[0056] S50, performing electroless copper deposition and electroplating treatment on the laminated board to realize hole metallizat...

Embodiment 2

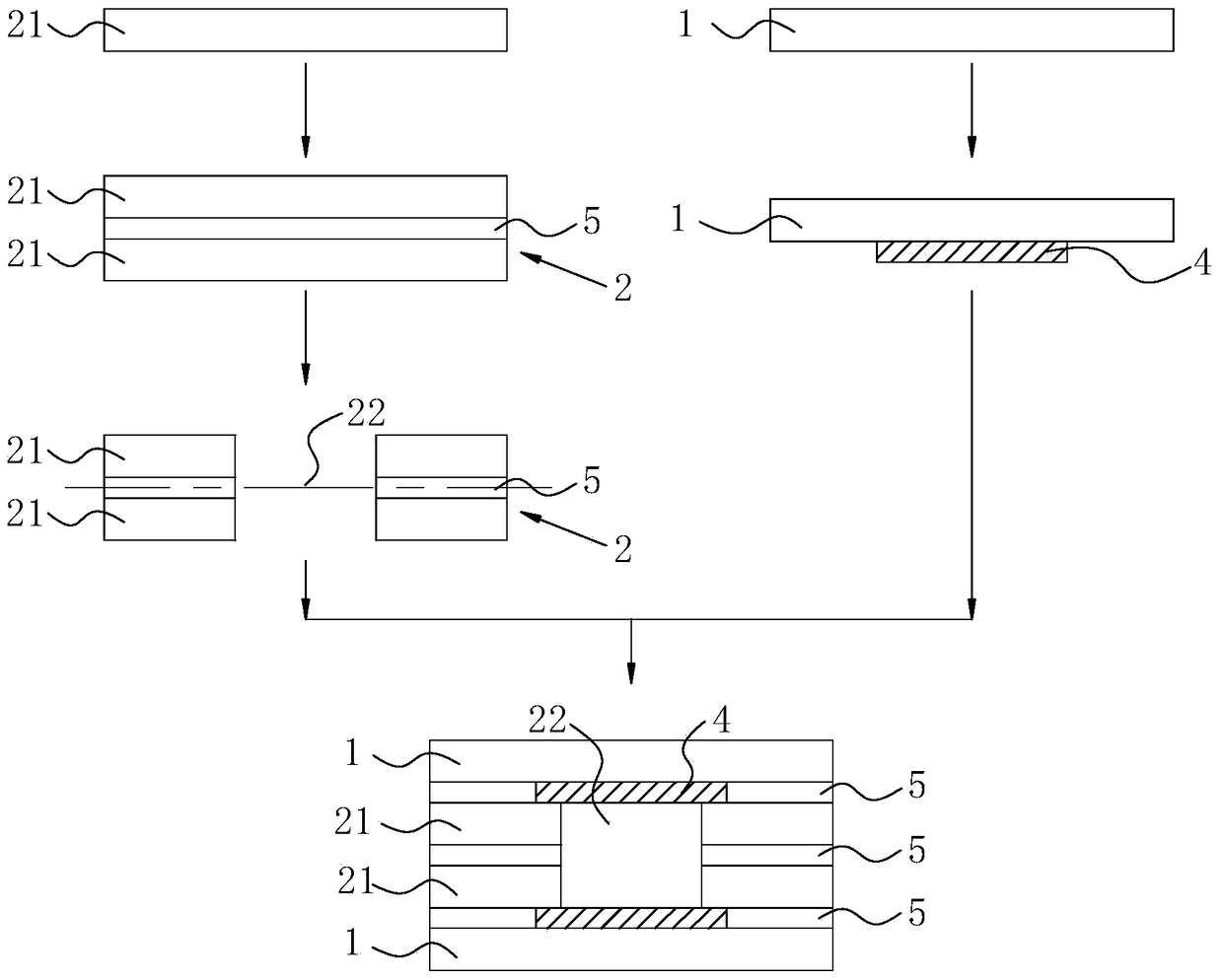

[0072] Such as figure 1 and image 3 Shown, a kind of manufacturing method of PCB comprises the following steps:

[0073] S10. Open a relief hole 22 on the sub-board 2;

[0074] S20. Provide a non-perforated core board, and make glue-resistant protrusions 4 on the end surface of the non-perforated core board adjacent to the sub-board 2 close to the sub-board 2;

[0075] S25. Baking the non-perforated core board with the glue-resistant protrusions 4, so that the glue-resistant protrusions 4 are cured on the non-perforated core board;

[0076] S30, providing a prepreg 5, pressing the non-perforated core board, the prepreg 5 and the sub-board 2, so that the glue-resisting protrusion 4 covers the end of the relief hole 22, forming a laminated board with a closed cavity;

[0077] S40, drilling the plywood, and performing post-drilling treatment;

[0078] S50, performing electroless copper deposition and electroplating treatment on the laminated board to realize hole metallizati...

Embodiment 3

[0094] Such as figure 1 and Figure 4 Shown, a kind of manufacturing method of PCB comprises the following steps:

[0095] S10. Open a relief hole 22 on the sub-board 2;

[0096] S20. Provide a non-perforated core board, and make glue-resistant protrusions 4 on the end surface of the non-perforated core board adjacent to the sub-board 2 close to the sub-board 2;

[0097] S25. Baking the non-perforated core board with the glue-resistant protrusions 4, so that the glue-resistant protrusions 4 are cured on the non-perforated core board;

[0098] S30, providing a prepreg 5, pressing the non-perforated core board, the prepreg 5 and the sub-board 2, so that the glue-resisting protrusion 4 covers the end of the relief hole 22, forming a laminated board with a closed cavity;

[0099] S40, drilling the plywood, and performing post-drilling treatment;

[0100] S50, performing electroless copper deposition and electroplating treatment on the laminated board to realize hole metallizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com