Ship energy management system based on hot redundancy controllers

An energy management system and controller technology, applied in the field of ship energy management system, can solve the problems of low reliability, complex configuration of ship power station, and inability to achieve non-stop maintenance and replacement, and achieve wide applicability, convenient operation, high performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

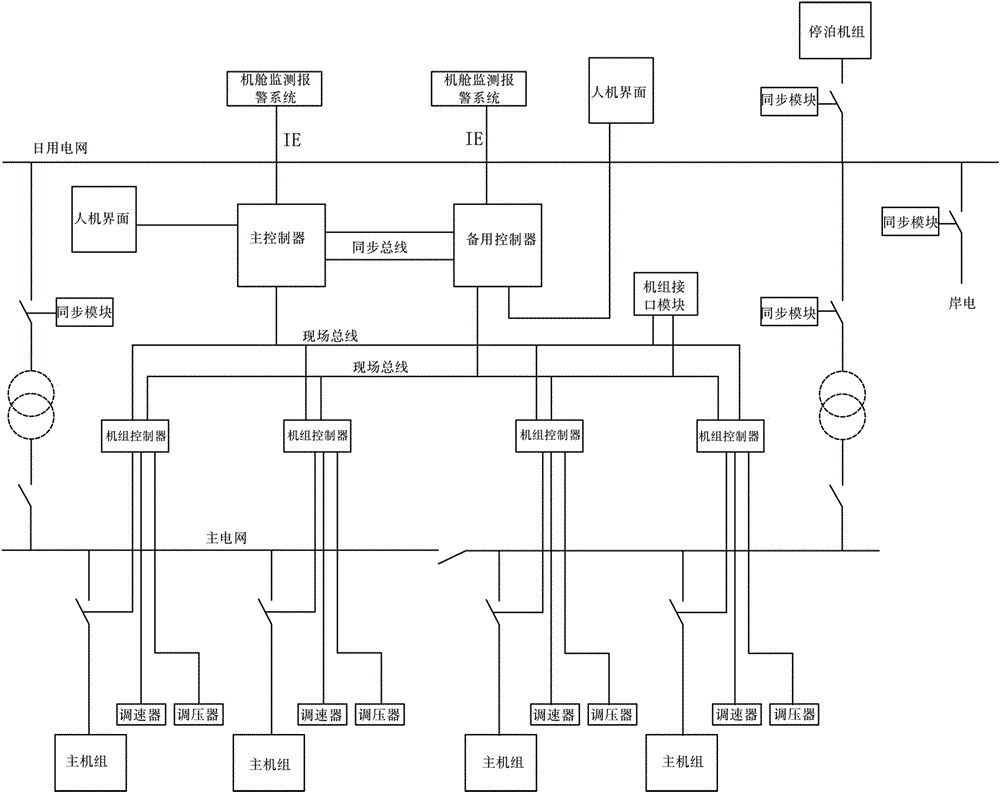

[0015] figure 1 Shown is a typical application schematic diagram of the present invention, which is an energy management system of a ship power station composed of four main units and one parking unit, including a main controller used as a main control station, and a backup control station One set of controllers will play the role of the main control station in the ship energy management system, and the other set will run in the state of the standby control station. The two sets of controllers are connected in parallel and run independently on the daily power grid. Mutual standby, in order to ensure the continuity of power supply and system reliability, the main controller and the standby controller both adopt hot redundant controllers and carry out real-time synchronous communication through the synchronization bus. Multiple unit controllers and unit interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com