A fuel control method and system applied to a circulating fluidized bed boiler

A circulating fluidized bed and fuel control technology, which is applied to fluidized bed combustion equipment, fuel for combustion in a molten state, and combustion methods, etc. Advanced problems, to achieve the effect of maintaining bed temperature balance and optimal control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

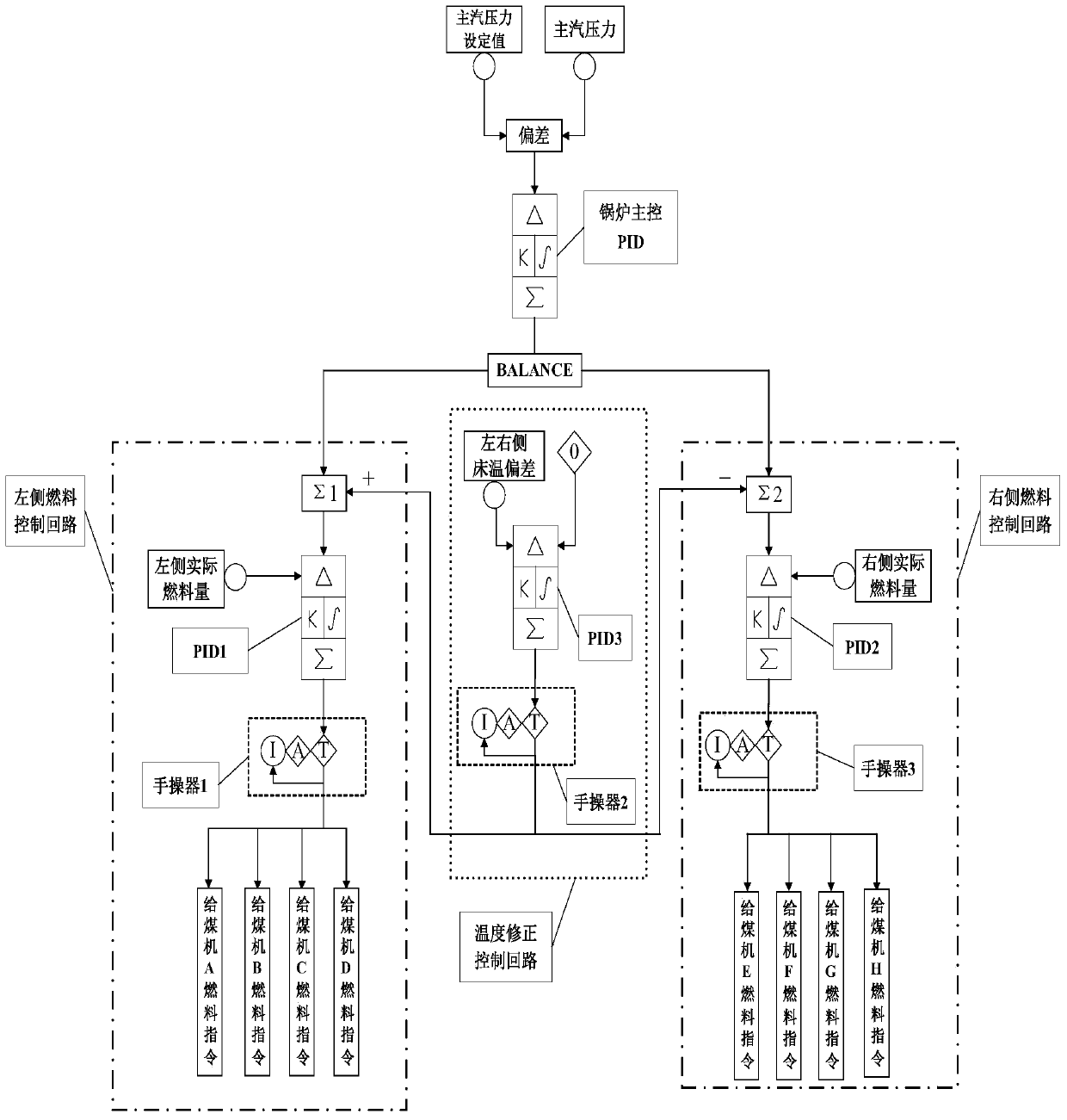

[0041] As a preferred implementation, the composition of the right fuel control loop:

[0042] It consists of adding block Σ2, proportional-integral-differential controller PID2, and hand-operated device 2 connected in sequence.

[0043] The addition block Σ2 adds the output of the balance controller and the output of the temperature balance loop into the proportional integral differential controller PID2, and completes the adjustment of the fuel quantity on the right side through the calculation function of PID2, and the calculation output of PID2 enters the right Each coal feeder corresponding to the side fuel control circuit completes the fuel adjustment process through the change of the coal feed amount of the coal feeder.

[0044] As a preferred embodiment, the present invention also adds a temperature correction control loop for correcting the left / right temperature deviation. The composition of the temperature balance control loop:

[0045] The left and right side tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com