Detection type purification type particle covered wire optical cable joint box

A technology for leather optical cables and splice boxes, which is applied in the field of purification devices for optical cable joints, and can solve problems such as low efficiency, incomplete removal, and unsimple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment, content of the invention will be further described:

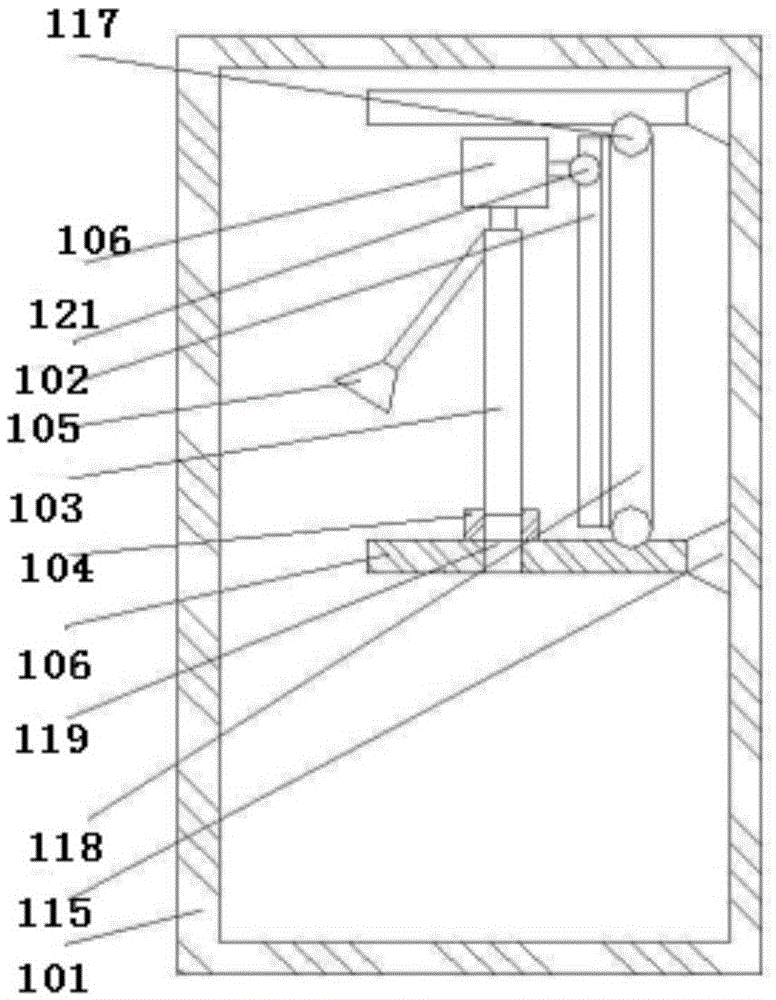

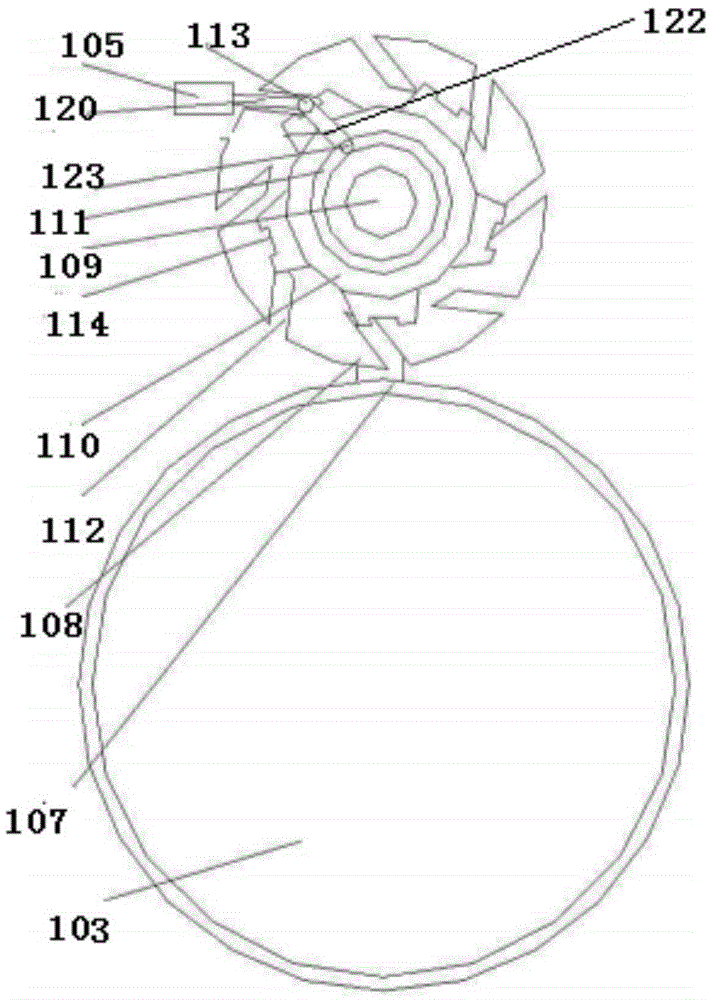

[0011] Detectable purification type particles are used for leather cable joint boxes, such as Figure 1-Figure 3 As shown, the splice box for the detection-type purification type of particulate matter used for leather cables includes a splice box body 11, a guide rail 12, a screw 13, a thread nut 14, a sheet body 15 and a motor 16, and the thread nut 14 passes through the base The seat is connected with the joint box body 11, the screw nut 14 is sleeved on the lead screw 13 adapted thereto, and one end of the lead screw 13 is connected with the motor 16, and the screw nut 14 is The other end of the bar 13 is connected to the sheet body 15 via the adjustment part, the motor 16 is connected to the guide rail 12 via the guide wheel 121, and the guide rail 12 is connected to the base; The adjustment part includes a positioning ring 17, and the positioning ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com