A vibration isolation system with controllable stiffness damping and inertia force and its control method

A vibration isolation system, inertial force technology, applied in inertial force compensation, vibration suppression adjustment, non-rotation vibration suppression and other directions, can solve problems such as unsatisfactory vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

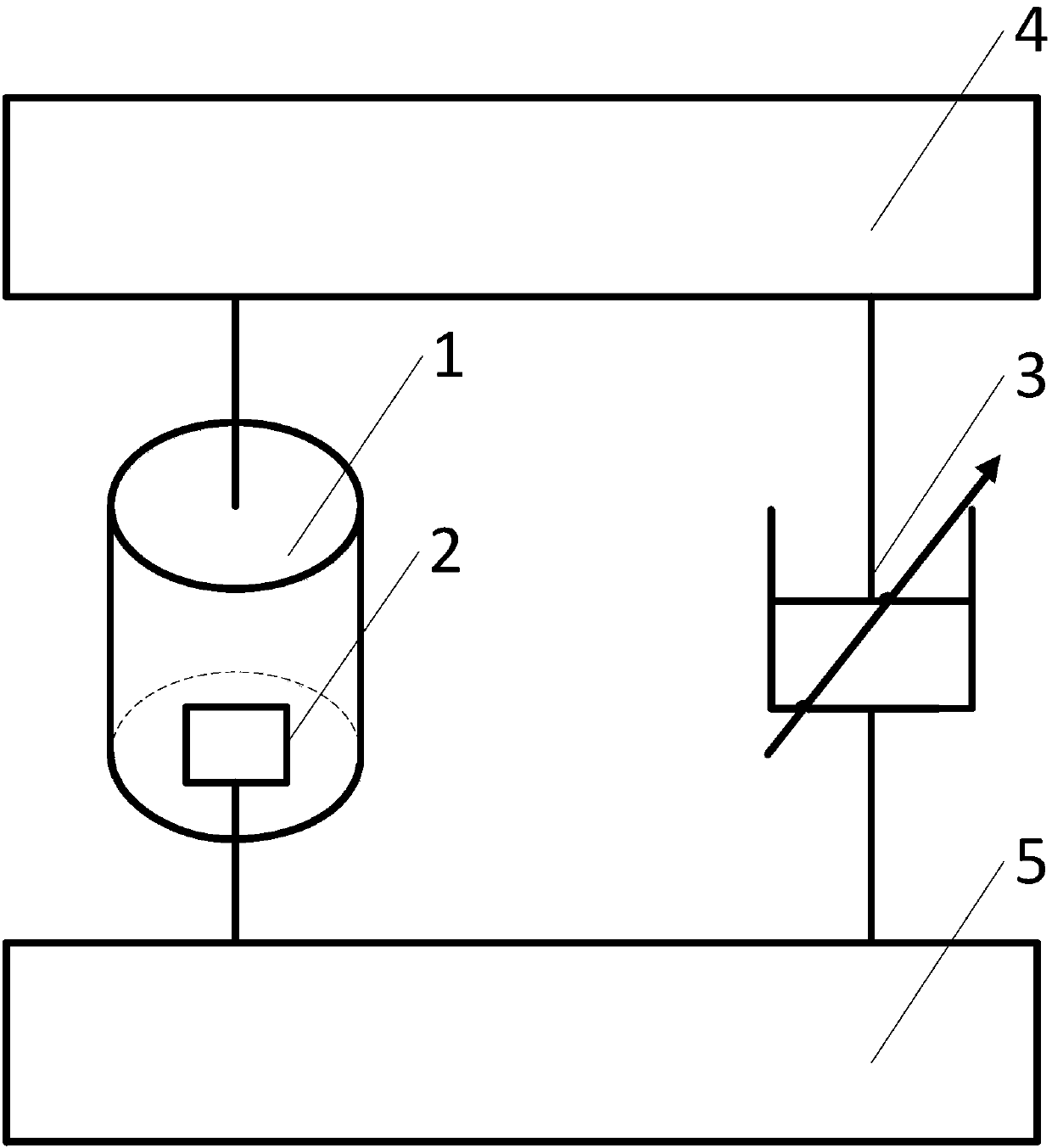

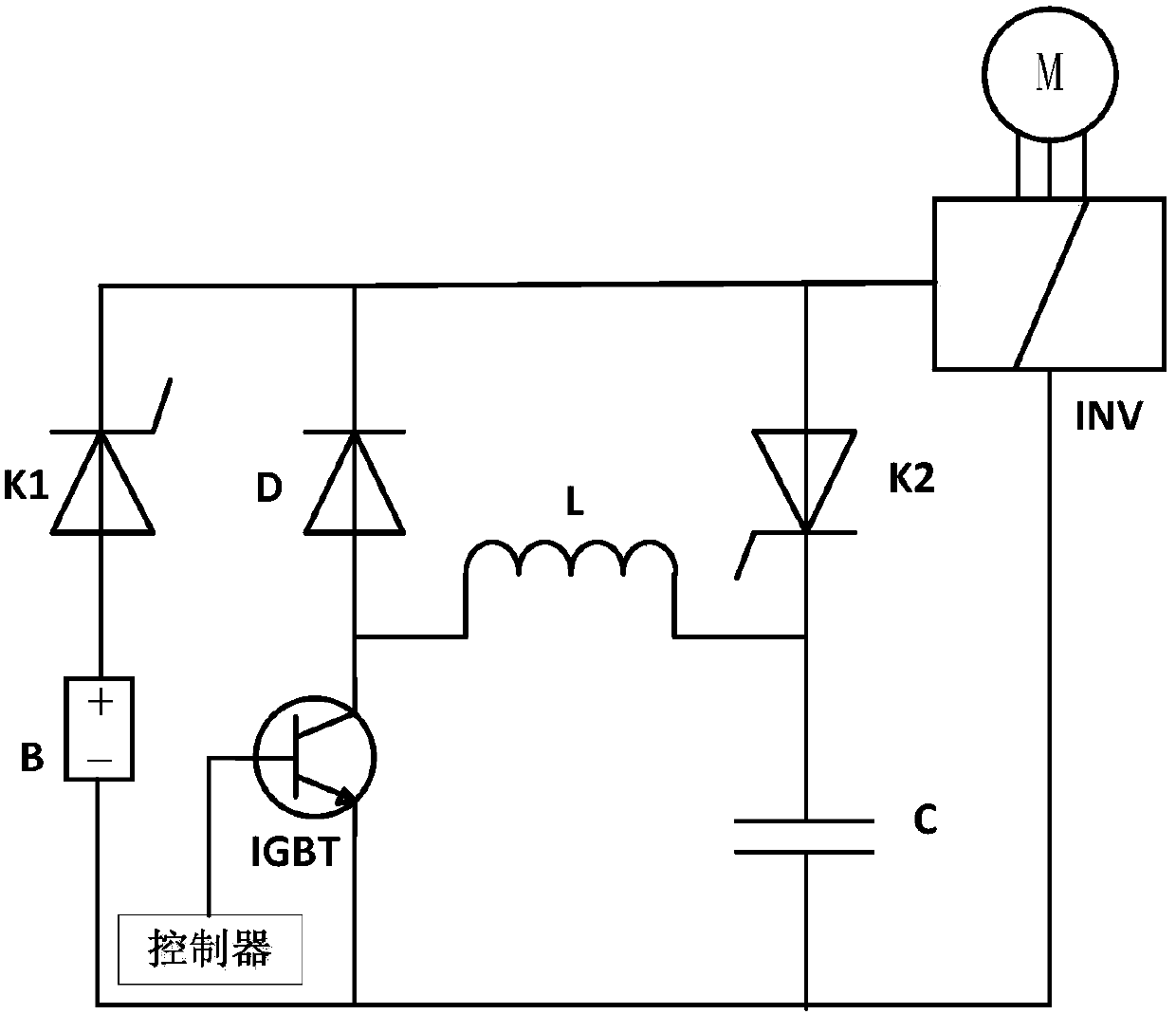

[0040] A vibration isolation system with controllable stiffness damping and inertia force, including a vibration isolation device and a control module;

[0041] In the vibration isolation device, an air spring 1, an inertial force generator 2, and a magnetorheological damper 3 are included; the inertial force generator 2 is placed in the air spring 1;

[0042] The air spring 1 is connected in parallel with the magneto-rheological damper 3; one end of the air spring 1 is connected to the vibrating mechanical equipment 4, and the other end of the air spring 1 is connected to the fixture 5; the magneto-rheological damper 3 One end is connected to the vibrating mechanical equipment 4, and the other end of the magneto-rheological damper 3 is connected to the fixture 5;

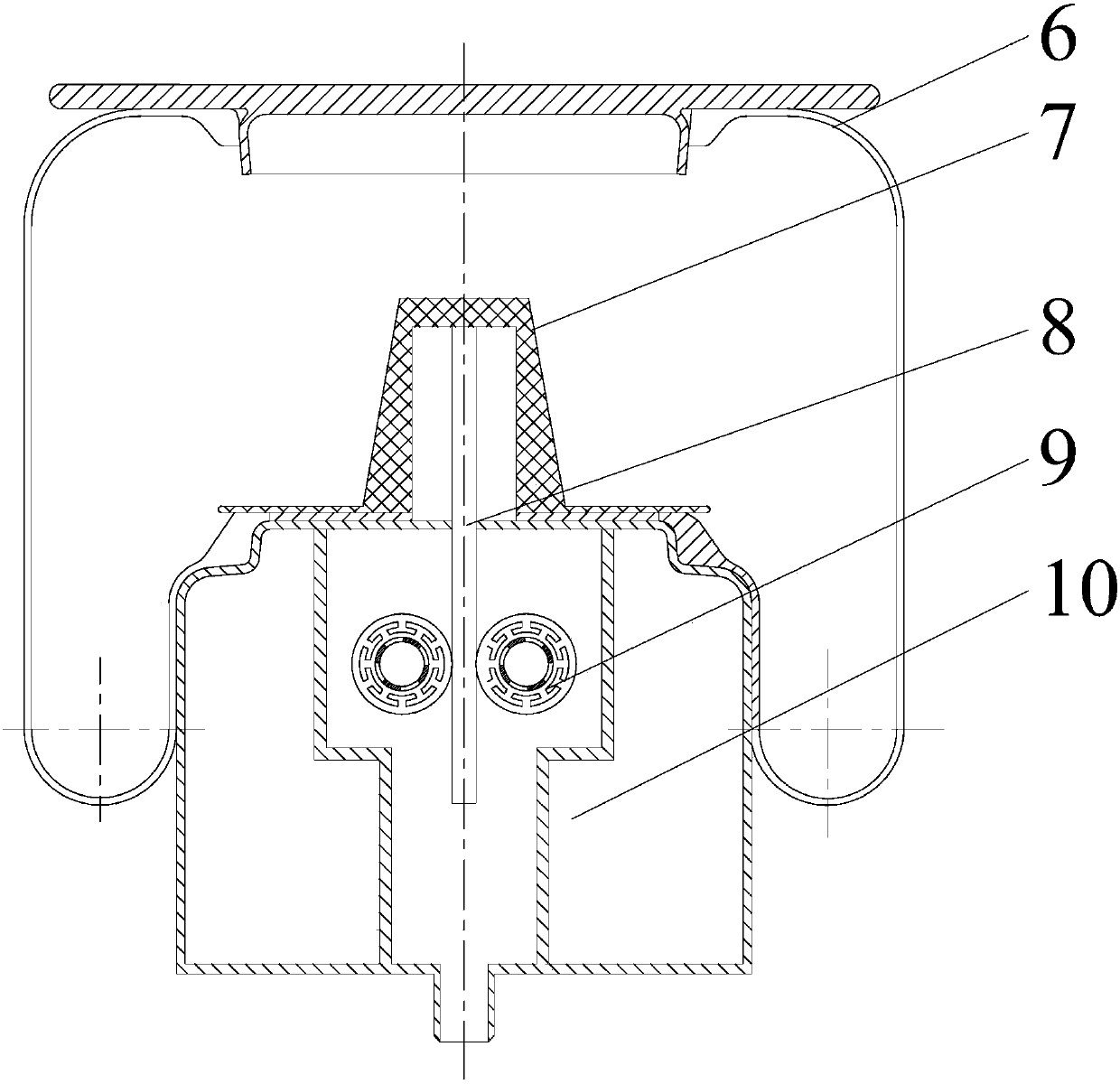

[0043] The air spring 1 includes an air spring body 6 and an air spring base 10; the air spring base 10 is placed in the center of the lower end of the air spring body 6, and the air spring body 6 and the air sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com