A two-axis rotating gluing head

A gluing head and gluing technology, which is applied in the field of gluing heads, can solve problems such as the inability to solve the problem of gluing head rotation, and achieve the effects of improving efficiency, expanding the scope of use, and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

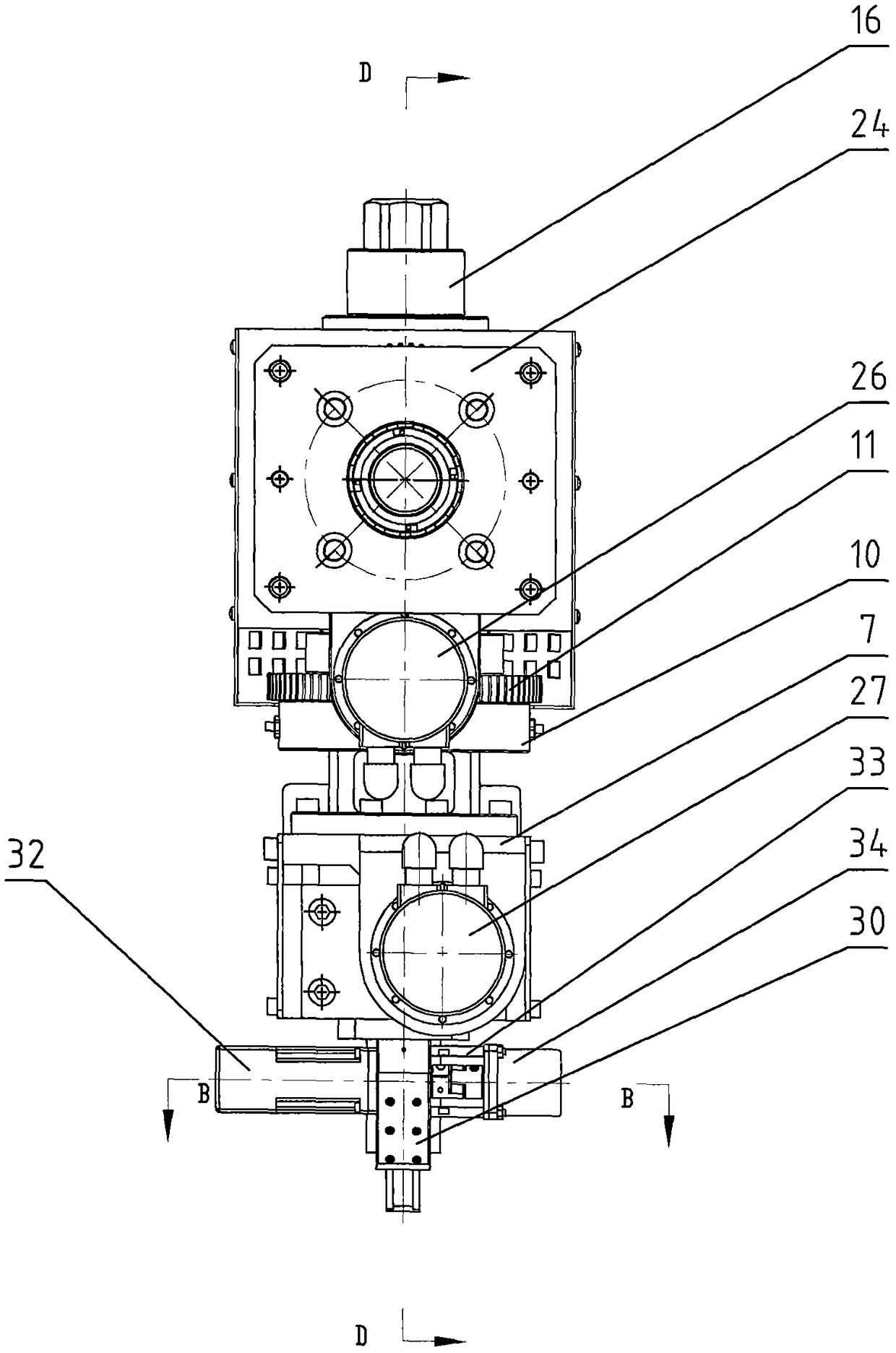

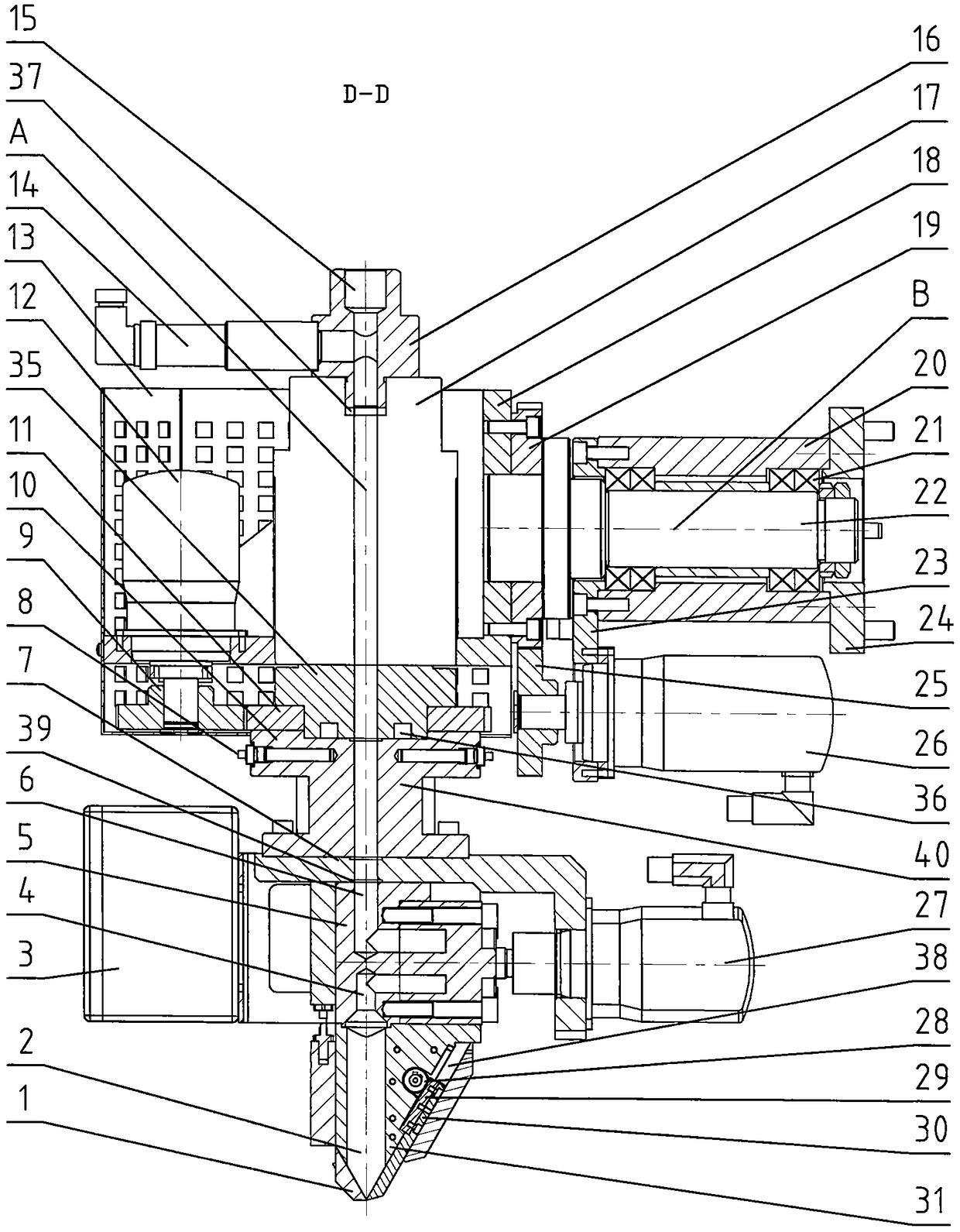

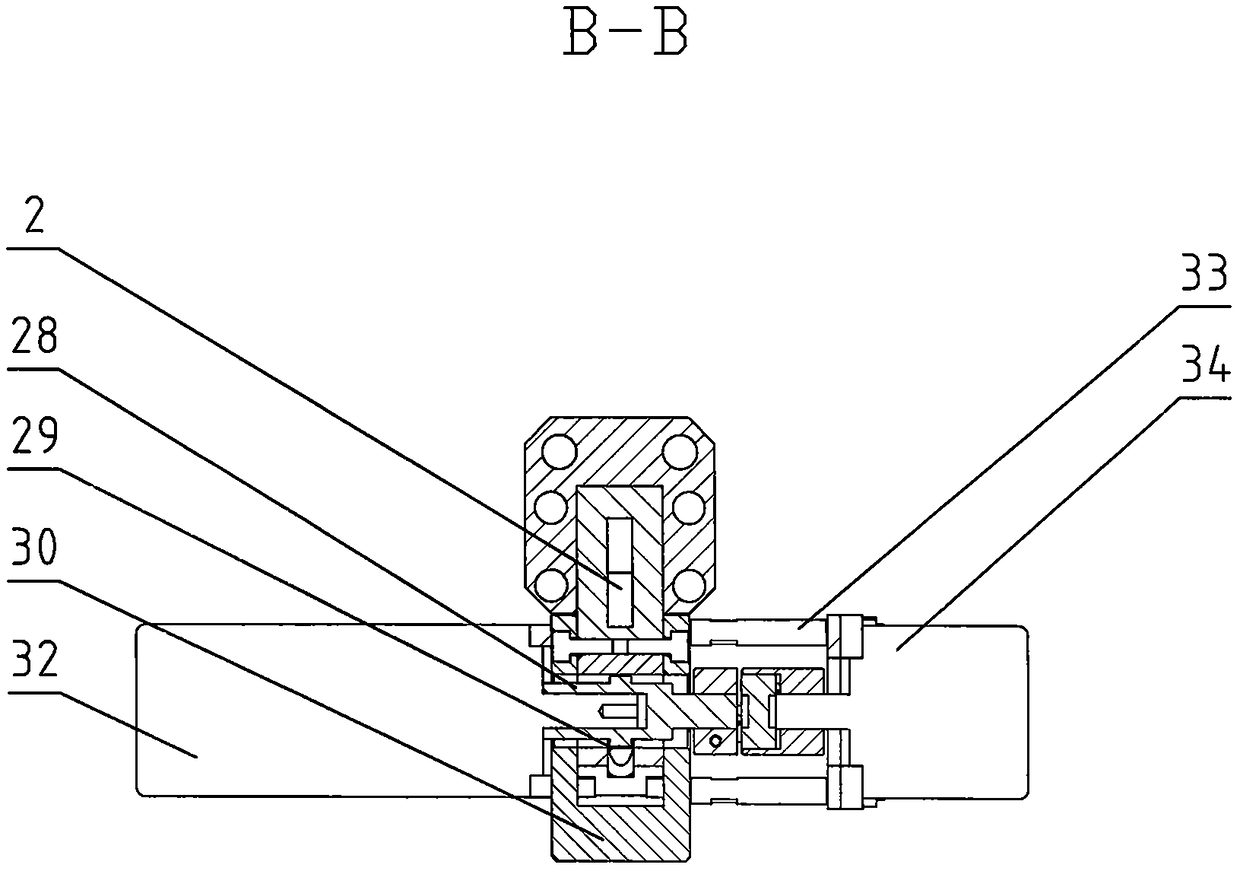

[0031] Embodiment 1: as Figure 1~3 Shown, further illustrate the present invention below in conjunction with accompanying drawing. A two-axis rotating gluing head, used for gluing one-component glue, is characterized in that it includes a gear C19, a gear D25, and a motor B26 that enable the gluing unit 1 to rotate in a vertical plane around the horizontal centerline B , and the gear A9, gear B11, and motor A12 that can make the gluing unit 1 rotate in the horizontal plane around the vertical center line A;

[0032] The connecting plate 24 is fixedly installed on the base of the gluing equipment, the fixed plate B23 and the connecting plate 24 are fixedly connected to the left side and the right side of the bearing seat 20 respectively, and a group of bearings 21 and the rotating shaft 22 are installed in the bearing seat 20, and the rotating shaft 22 The left end passes through the inner hole of the gear C19 and the housing 18 which are fixed together, the housing 18 and th...

Embodiment 2

[0043] Embodiment 2: as Figure 1~3 As shown, what is different from Embodiment 1 is that the gear C19, the gear D25, and the motor B26 do not rotate.

[0044] The motor A12 drives the gear B11 to rotate around the head body 35, and the gluing unit 1 rotates around the vertical centerline A.

Embodiment 3

[0045] Embodiment 3: as Figure 1~3 As shown, what is different from Embodiment 1 is that the gluing unit 1 only includes the gear A9, the gear B11, and the motor A12 that can make the gluing unit 1 rotate in the horizontal plane around the vertical centerline A; The glue unit 1 is a gear C19, a gear D25, a motor B26, a bearing 21, a rotating shaft 22, etc. that rotate in a vertical plane around the horizontal center line B.

[0046] The motor A12 drives the gear B11 to rotate around the head body 35, and the gluing unit 1 rotates around the vertical centerline A.

[0047] The gluing head of embodiment 2 and embodiment 3 is suitable for coating track is planar, and the cross-sectional shape of glue strip is the workpiece of square, rectangle, ellipse or steamed bun shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com