Printing roller transferring trolley

A technology of trolleys and version rollers, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of difficult packaging, bruises and damage of version rollers, and achieve the effect of strong versatility and large loading quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

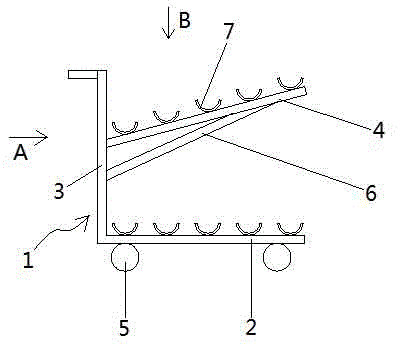

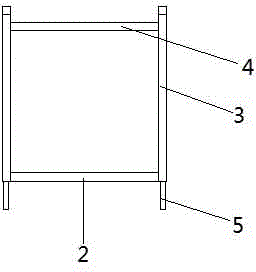

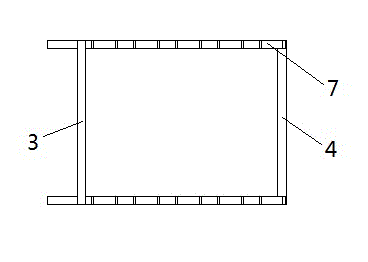

[0015] combine figure 1 with figure 2 , the present invention includes a vehicle frame 1 provided with wheels 5, the vehicle frame 1 includes a rectangular underframe 2, and one side of the underframe 2 is provided with a vertical rectangular bracket 3. An upper frame 4 is also provided above the underframe 2, such as image 3 As shown, the top view projection of the upper frame 4 and the bottom frame 2 coincides.

[0016] One side of the upper frame 3 is fixedly connected with the support 3, and an inclined support frame 6 is provided below the upper frame 4. One end of the support frame 6 is connected to the support 3, and the other end is fixedly connected with the side of the upper frame 4.

[0017] In this embodiment, the upper frame 4 is inclined upward. The angle of inclination between upper shelf 4 and the horizontal plane is 15°. The upper shelf 4 is tilted upwards. One is to make the center of gravity of the plate rollers placed on the upper shelf 4 backward, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com