Cigarette packing box provided with inner package having adhesive cover plate structure, and blank used for constructing inner package

A technology of inner packaging and packaging box, which is applied in the field of blanks for constructing the inner packaging, can solve the problems of complicated operation, increased production cost, complicated production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

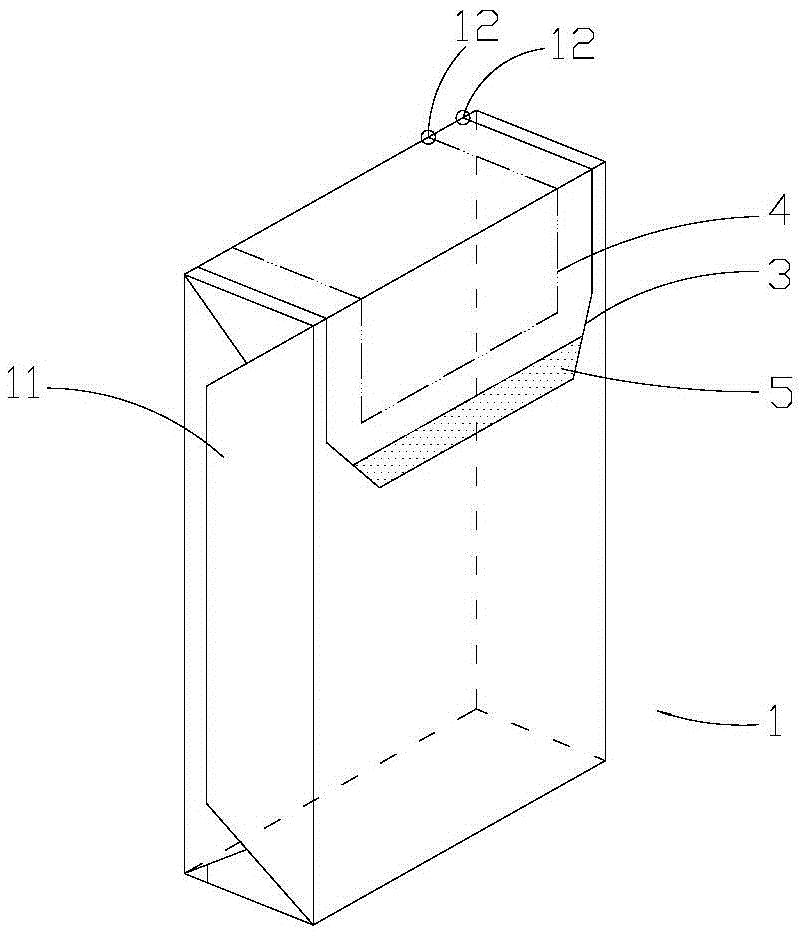

[0052] Cigarette packing box, including inner frame 2, inner packing 1 and outer packing box.

[0053] inner frame such as Figure 5 As shown, a piece of cardboard blank is folded to form a box-like structure, which has a front wall, left and right side walls and a lower end surface, wherein the front wall has an extraction opening 21 .

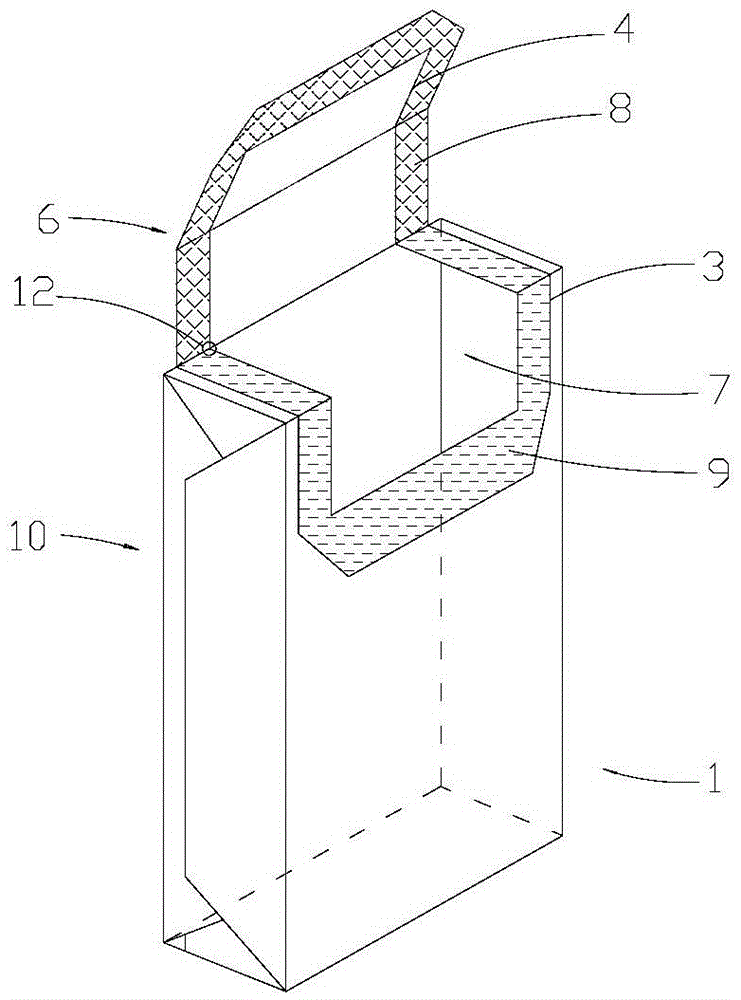

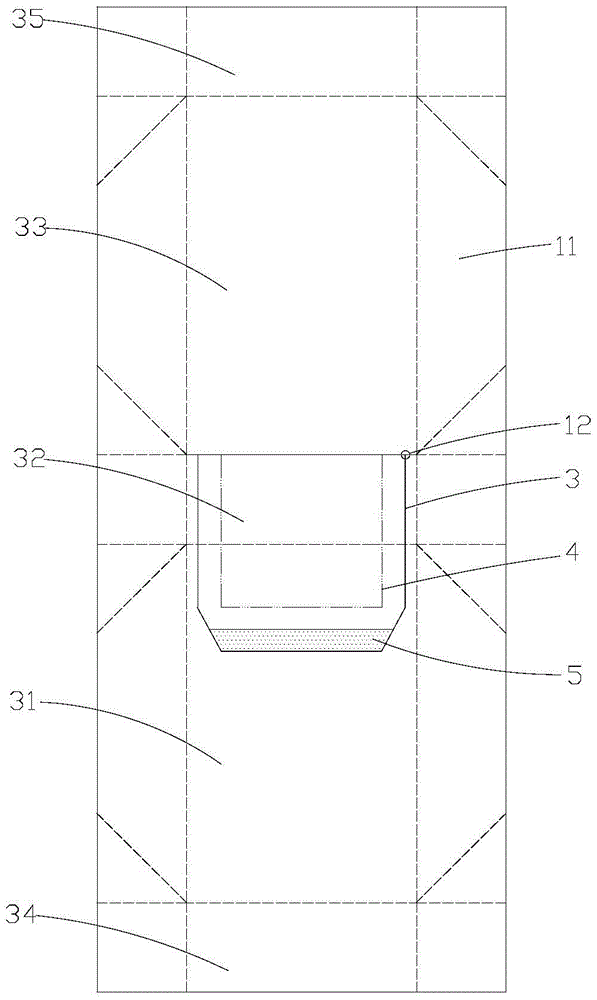

[0054] A piece of blank is wrapped and sealed on the outside of the box-shaped inner frame, and the unfolded structure of the blank is as follows: image 3 shown. The blank has a front lower edge piece 34, a front wall piece 31, an upper end piece 32, a rear wall piece 33 and a rear lower edge piece 35, which are sequentially arranged along the middle (not shown in the figure) and connected by folding lines. It is folded along the folding line into a box-like structure matching the size of the inner frame, and constitutes the front and rear walls, left and right side walls, upper and lower end surfaces of the inner package, and the overlapp...

Embodiment 2

[0063] Similar to the structure of Embodiment 1, the difference is that by adjusting the respective cutting depths of the weakened line 3 of the cover sheet and the weakened line of the take-out port 4, the exposed adhesive layer area 8' is located on the outer surface of the inner package body 10, and the cover The corresponding position of the sheet 6 is the exposed upper substrate layer 13 . like Figure 10 shown.

[0064] This is by adjusting the cutting depth of the weakening line, so that the cover sheet weakening line 3 cuts the upper substrate layer of the blank, and the take-out port weakening line 4 cuts the adhesive layer and the base substrate layer of the blank.

[0065] In addition, deformations were made to the inner frame, such as Image 6 shown. The rear wall of the inner frame is composed of a pair of rear flaps 22 respectively connected with the left and right side walls to increase the stability of the inner frame.

Embodiment 3

[0067] In order to further increase the stability of the inner frame, it is also possible to construct such as Figure 7 The inner frame shown, which has a complete rear wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com