Tooling for cable pulling or replacing of ship

A technology for cables and ships, which is applied in the field of tooling for pulling or replacing cables on ships. It can solve the problems of ship cable size and weight, inconvenient construction, hidden safety hazards, etc., and achieve good stability and improve fluency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

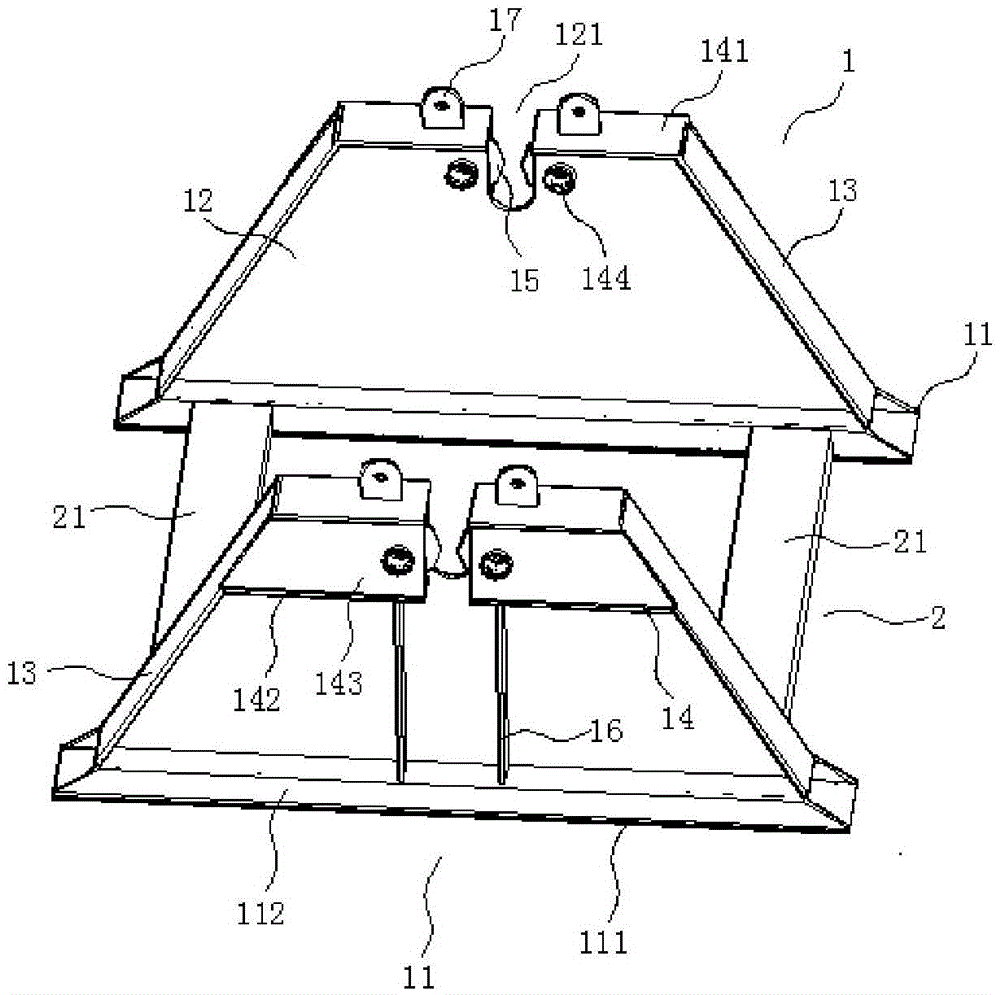

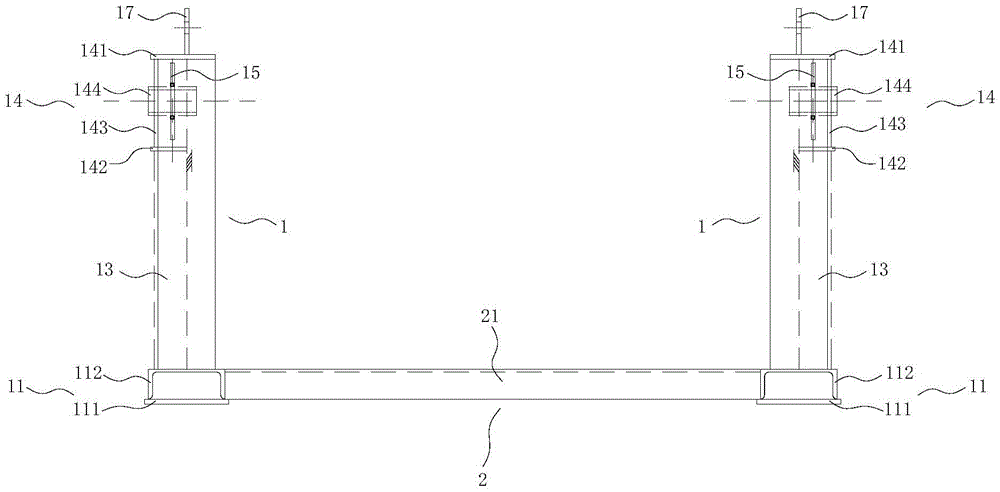

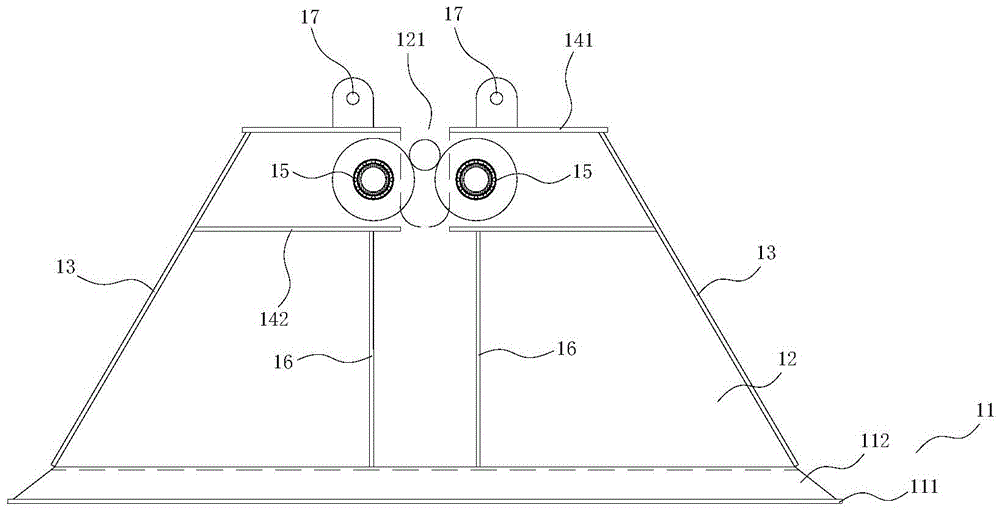

[0024] The invention provides a tool for pulling or replacing cables on ships, such as Figure 1-3 As shown, it includes two brackets 1 for placing the cable reel, and under the action of the winch, the cable is released. Specifically, the cable reel is placed on the two brackets 1 through the reel shaft; in the two brackets 1 A fixing frame 2 is fixedly connected therebetween to strengthen the connection between the two brackets 1 and make the two brackets 1 more stable.

[0025] The above-mentioned bracket 1 includes a base 11, a web 12, a side plate 13, a bearing seat 14 and a bearing 15, wherein:

[0026] Such as figure 2 as well as image 3 As shown, the base 11 is affixed to the fixed frame 2, which includes a base cover 111 and a first channel steel 112 fixed on the base cover 111, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com