Earthquake-resistant building support connecting structure and method

A technology for connecting structures and connecting flanges, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of connection failure, inconvenient disassembly and assembly, and easy cracks, etc., to achieve convenient installation and fixing, good seismic performance, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

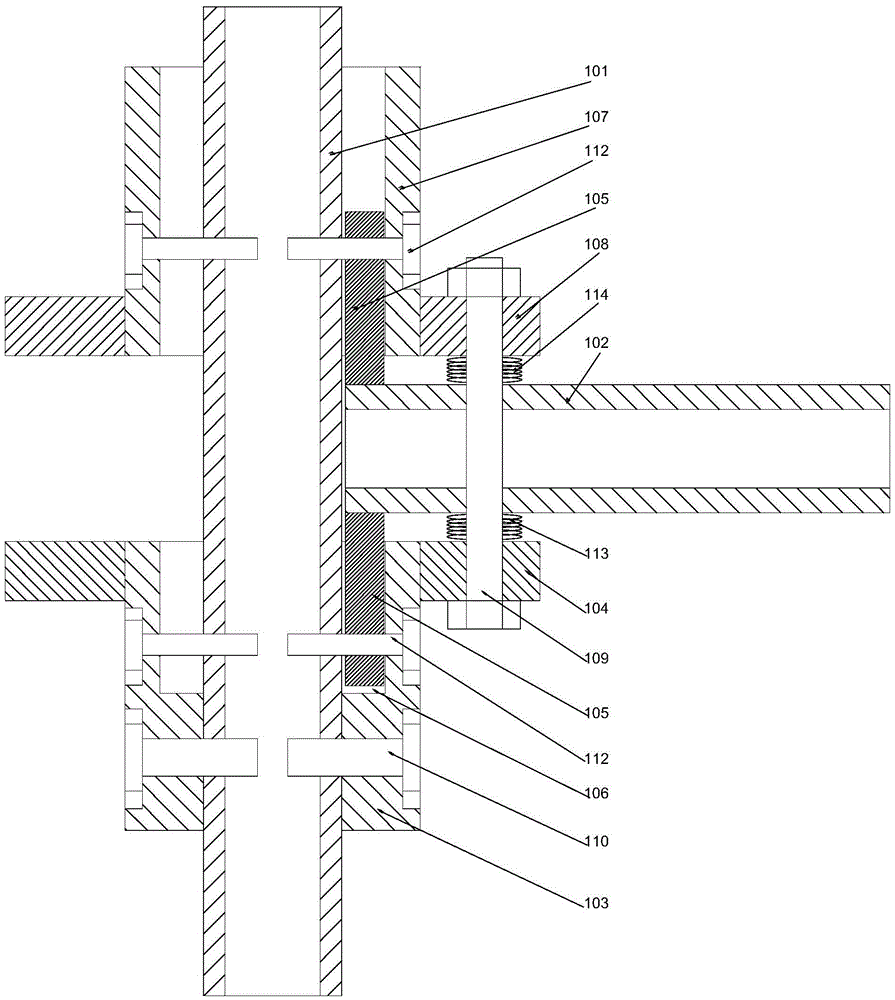

[0026] like figure 1 As shown, a connection structure for an earthquake-resistant building support includes a longitudinal steel pipe 101 and a transverse steel pipe 102 made of square steel. A supporting flange 104 is provided, a stepped groove 106 is provided on the inner wall of the upper end of the fixed sleeve 103, and snap-in parts 105 are respectively provided on the upper and lower ends of the end of the horizontal steel pipe 102, and the snap-in part 105 and the transverse steel pipe 102 are perpendicular to each other, the clamping part 105 at the lower part can be embedded in the stepped groove 106, and a through hole is provided on the transverse steel pipe 102, and the through hole The axis of the hole is parallel to the line connecting the two clamping parts 105, the support flange 104 is provided with a fixing hole, and the longitudinal steel pipe 101 is fitted with a moving sleeve 107, and the The fixed sleeve 103 can slide up and down along the longitudinal s...

Embodiment 2

[0032] On the basis of Embodiment 1, this embodiment also discloses a method for connecting earthquake-resistant building supports, including the following steps:

[0033] S1: Set the fixing sleeve 103 on the longitudinal steel pipe 101 so that it is fixed relative to the longitudinal steel pipe 101 and cannot move longitudinally;

[0034] S2: Put the fixing bolt 109 through the fixing hole on the support flange 104, and put the damping spring 113 on the fixing bolt 109;

[0035] S3: Connect the clamping part 105 at the lower end of the transverse steel pipe 102 into the stepped groove 106 inside the fixed sleeve 103, make the lower end surface of the transverse steel pipe 102 fit on the upper end surface of the lower damping spring 113, and make the lower end surface The clamping part 105 is clamped in the cavity between the stepped groove 106 and the outer wall of the longitudinal steel pipe 101;

[0036] S4: Put the upper damping spring 114 on the fixing bolt 109, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com