High-reliability S-shaped quick metal connecting buckle

A metal connection and reliability technology, applied in the direction of connection components, detachable fasteners for friction clamping, mechanical equipment, etc., can solve the problems of complex metal buckle structure, difficult to manufacture, etc., achieve good finish, low cost, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

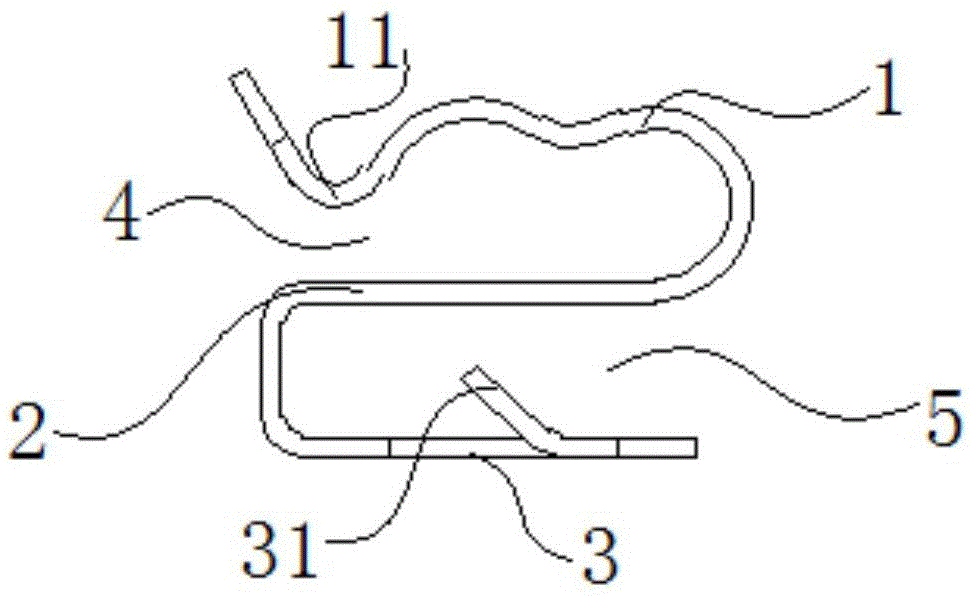

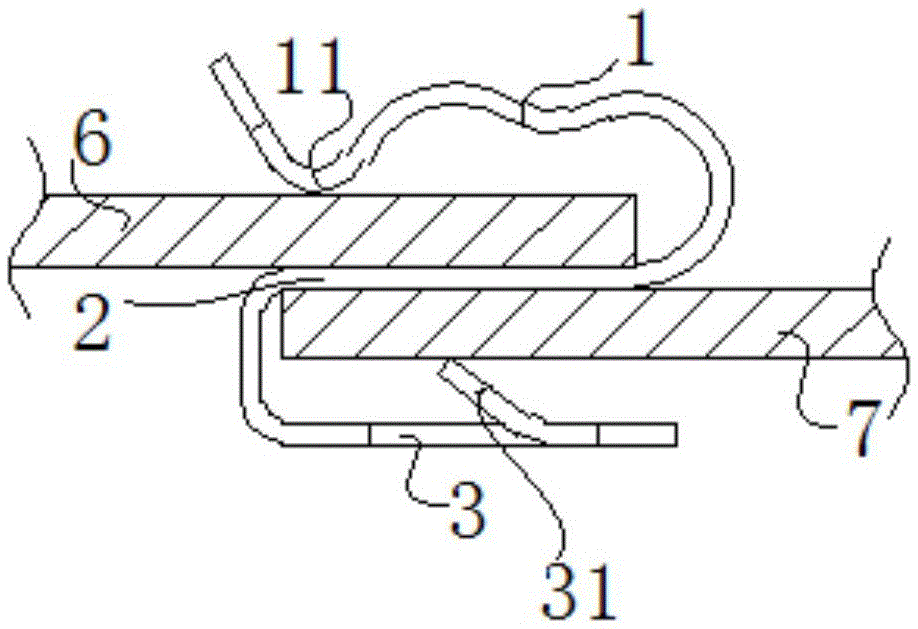

[0030] A high-reliability S-type fast metal connection buckle, such as figure 1 , figure 2 As shown, it is used to connect two assemblies together. The metal connection buckle is an S-shaped elastic metal part. Between the side plate 1 and the middle plate 2 is formed an upper side card slot 4 for clamping the upper side assembly 6, and between the lower side plate 3 and the middle plate 2 is formed a lower side card slot for clamping the lower side assembly 7 5. The opening directions of the upper card slot 4 and the lower card slot 5 are opposite. The open end of the upper side plate 1 is tilted upwards. The middle plate 2 is a horizontal plate, and the upper surface and the lower surface of the middle plate 2 are both horizontal planes. The lower side plate 3 is a horizontal plate. The upper side plate 1 is provided with a V-shaped protrusion 11 facing the middle plate 2. The V-shaped protrusion 11 and the middle plate 2 are used to apply pressure to the upper assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com