Foldable support mechanism

A technology of folding supports and lugs, which is applied in the direction of supporting machines, mechanical equipment, machine tables/brackets, etc., can solve the problems of small supporting force of supporting equipment, heavy supporting force, and difficulty in supporting large-tonnage mechanical parts, etc., to achieve Convenient packing and carrying, stable and reliable support, fast and stable recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

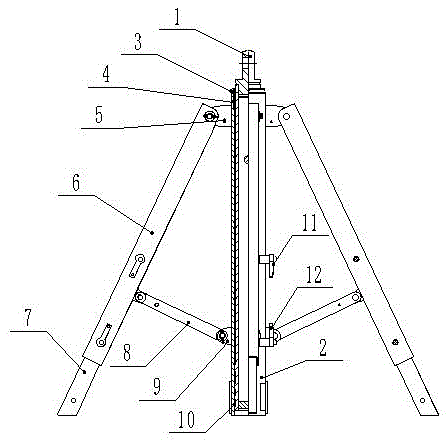

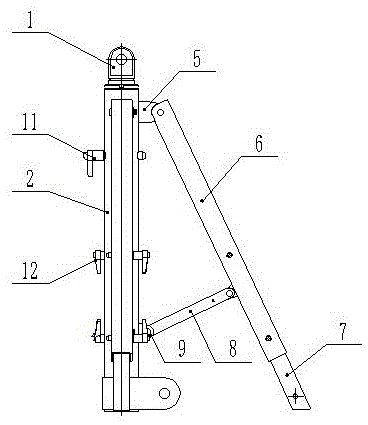

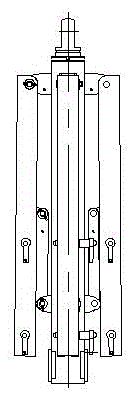

[0023] Such as Figure 1-Figure 4 As shown, the foldable support mechanism includes a telescopic rod 1, a fixed rod 2, an end cover 3, a composite bearing 4, at least three hollow outriggers 6, at least three movable outriggers 7, a pull rod 8, a support ring 10, a first L Type quick-release pin 11, the second L-shaped quick-release pin 12, the telescopic rod 1 and the fixed rod 2 are vertically arranged, and the fixed rod 2 with the upper end open and the lower end closed is set on the outside of the telescopic rod 1, and the support The ring 8 is arranged at the lower end of the telescopic rod 1, the composite bearing 4 and the end cap 3 are arranged at the upper end of the telescopic rod 1, and the end cap 3 is arranged above the composite bearing 4 and below the head of the telescopic rod 1 to close the upper end of the fixed rod 2 A plurality of upper lugs 5 corresponding to the legs 6 are evenly arranged on the upper part of the outer wall of the fixed rod 2, a plurality...

Embodiment 2

[0030] Such as Figure 1-Figure 4 As shown, the foldable support mechanism includes a telescopic rod 1, a fixed rod 2, an end cover 3, a composite bearing 4, at least three hollow outriggers 6, at least three movable outriggers 7, a pull rod 8, a support ring 10, a first L Type quick-release pin 11, the second L-shaped quick-release pin 12, the telescopic rod 1 and the fixed rod 2 are vertically arranged, and the fixed rod 2 with the upper end open and the lower end closed is set on the outside of the telescopic rod 1, and the support The ring 8 is arranged at the lower end of the telescopic rod 1, the composite bearing 4 and the end cap 3 are arranged at the upper end of the telescopic rod 1, and the end cap 3 is arranged above the composite bearing 4 and below the head of the telescopic rod 1 to close the upper end of the fixed rod 2 A plurality of upper lugs 5 corresponding to the legs 6 are evenly arranged on the upper part of the outer wall of the fixed rod 2, a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com