A cleaning method for sugar evaporation tank

A technology for evaporating tanks and sugar, which is applied in the cleaning field of sugar evaporating tanks, and can solve the problems of chemical cleaning agents polluting the environment, evaporating tank cleaning equipment, complex methods, and high cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

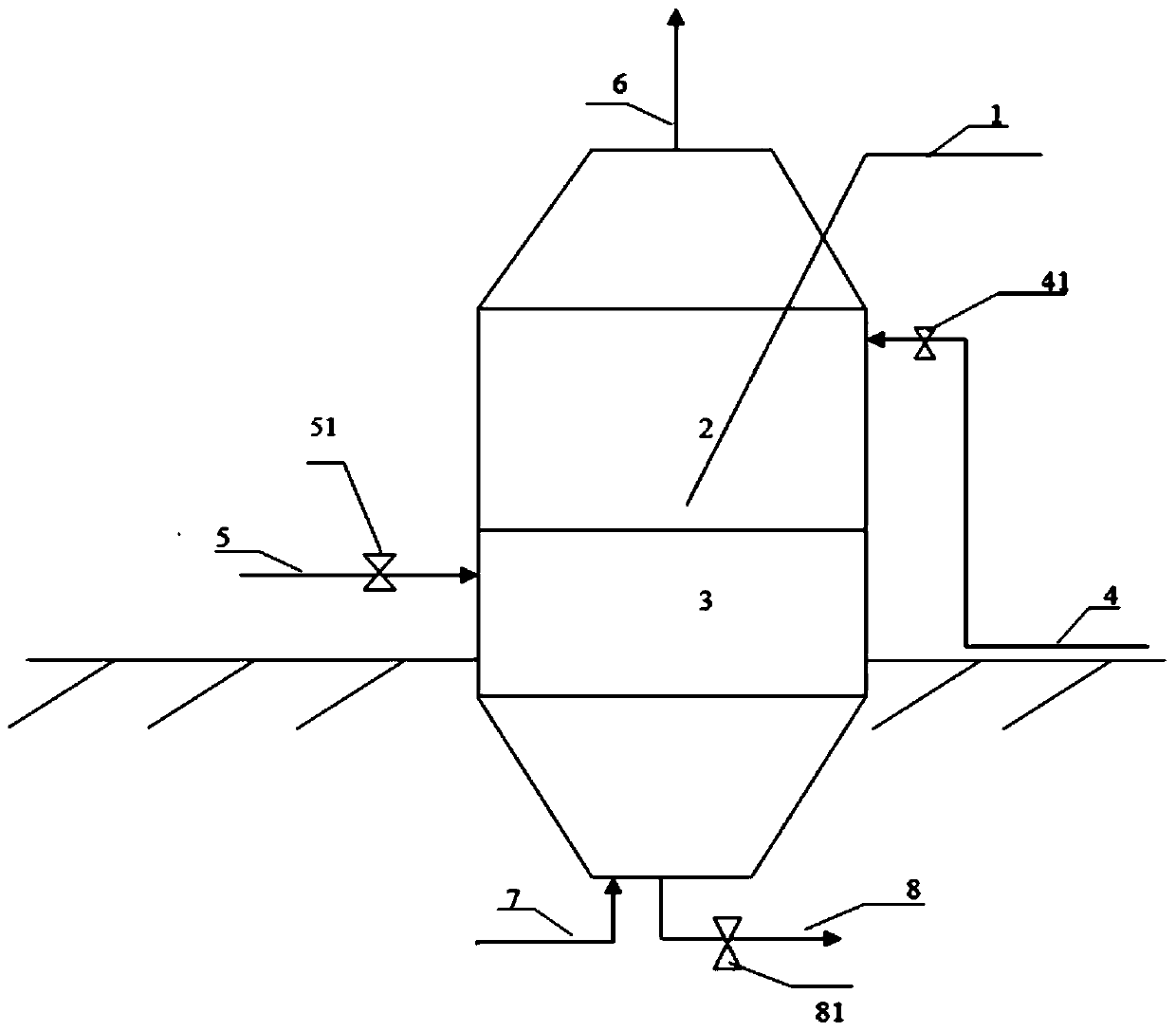

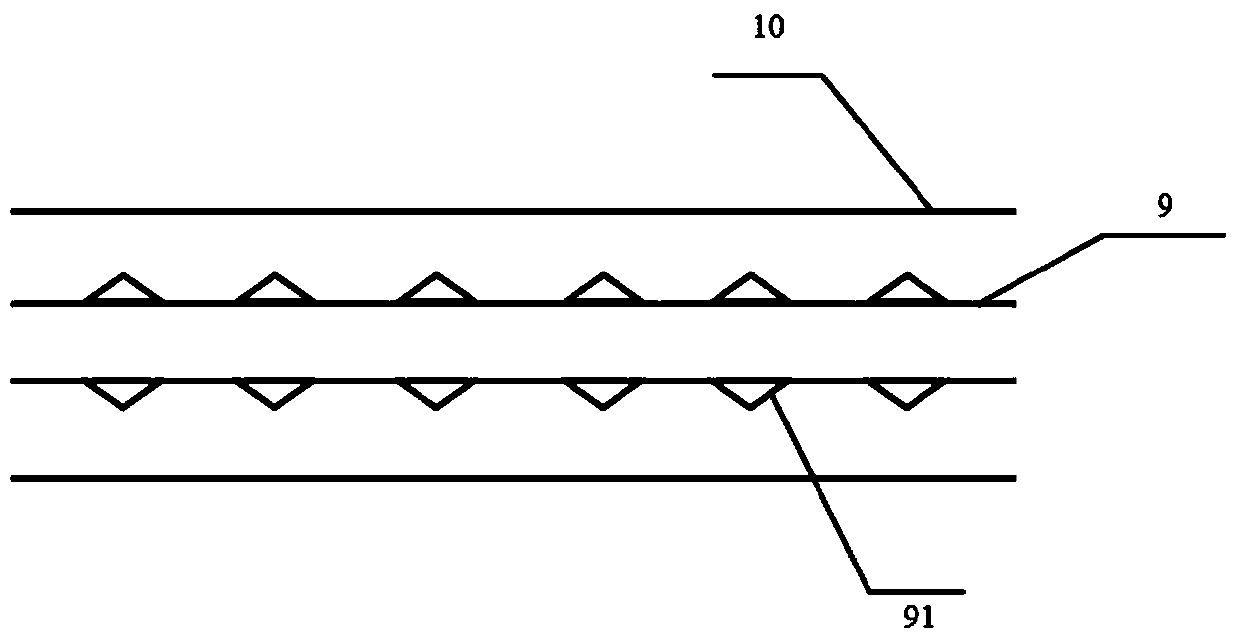

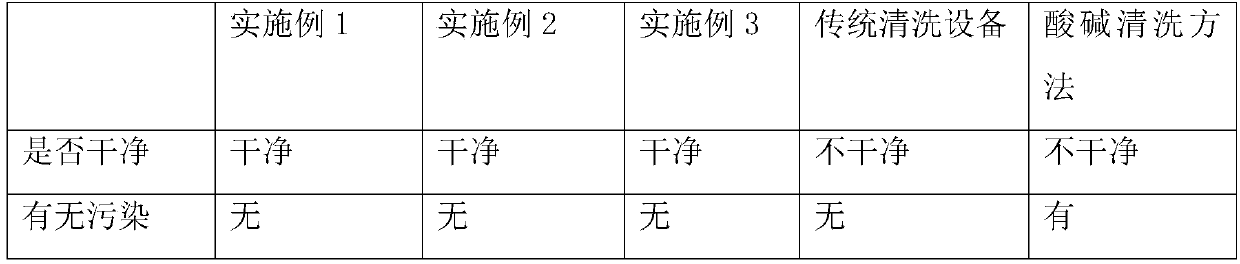

[0020] After 5 days of use, the 1# evaporator tank was switched out for cleaning. During the cleaning and descaling process of the evaporator tank, each component of the figure 1 and figure 2 Processed and assembled, open the cold water valve (41), rinse the residual juice with clean water for 5 minutes, and open the sewage valve (81), the residual juice that is easier to clean is cleaned, then close the cold water valve (41), and then open Exhaust gas valve (51), let the exhaust gas dry for 7 hours, control the temperature in the evaporation tank at about 120°C, and open the cold water valve (41) to pour cold water for 3 minutes when the drying time is 1.5, 3, 4.5, and 6 hours respectively , clean up the stubborn residual juice on the wall of the evaporating tank until 7 hours later, close the waste gas valve (51), let the evaporating tank cool down to normal temperature naturally, make the scale easily fall off through thermal expansion and contraction, and use a 60MPa hig...

Embodiment 2

[0022] The 4# evaporating tank is used for 3 days and then the tank is switched out for general cleaning. During the cleaning and descaling process of the evaporating tank, each component of the evaporating tank is figure 1 and figure 2 Processed and assembled, open the cold water valve (41), rinse the residual juice with clean water for 8 minutes, and open the sewage valve (81), the residual juice that is easier to clean is cleaned, then close the cold water valve (41), and then open Exhaust gas valve (51), let the exhaust gas dry the tank for 7.5 hours, control the temperature at about 135 ° C, and open the cold water valve (41) to pour cold water for 1 minute when the drying tank is 1, 3, 4.5, 6, and 7.5 hours respectively, Clean up the stubborn residual juice on the wall of the evaporating tank. After 7.5 hours, close the waste gas valve (51), let the evaporating tank cool down to normal temperature naturally, and make the scale easily fall off through thermal expansion a...

Embodiment 3

[0024] The 5# evaporating tank is used for 3 days and then the tank is switched out for general cleaning. During the cleaning and descaling process of the evaporating tank, each component of the evaporating tank is figure 1 and figure 2 Processed and assembled, open the cold water valve (41), rinse the residual juice with clean water for 10 minutes, and open the sewage valve (81), the residual juice that is easier to clean is cleaned, then close the cold water valve (41), and then open Exhaust gas valve (51), let the exhaust gas dry the tank for 8 hours, control the temperature at about 150°C, and respectively open the cold water valve (41) and pour cold water for 5 minutes when the tank is dried for 2, 4, 6, and 8 hours to clean and evaporate For the stubborn residual juice on the tank wall, after 8 hours, close the waste gas valve (51), let the evaporation tank cool down to normal temperature naturally, and make the scale easily fall off through thermal expansion and contra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap