Wine jar leak detection apparatus

A detection device and leak detection technology, which is applied to the measuring device, detects the appearance of fluid at the leak point, the direction of the instrument, etc., can solve the problems of low efficiency and cumbersome procedures, and achieve high efficiency, simple and reasonable structural design, and good reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

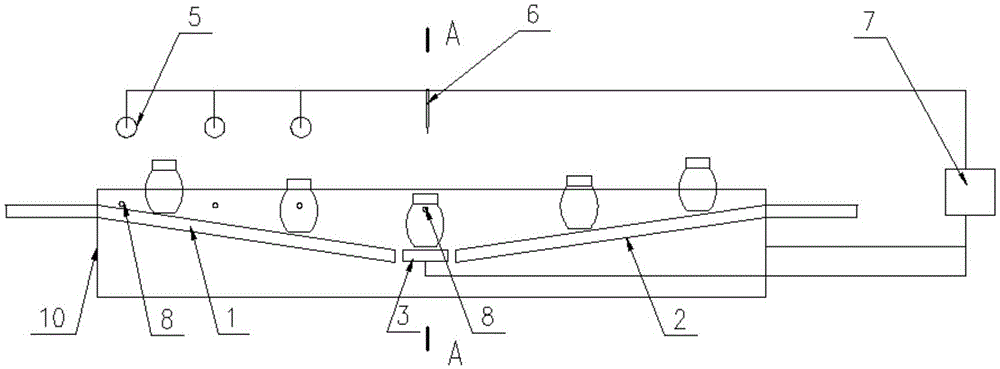

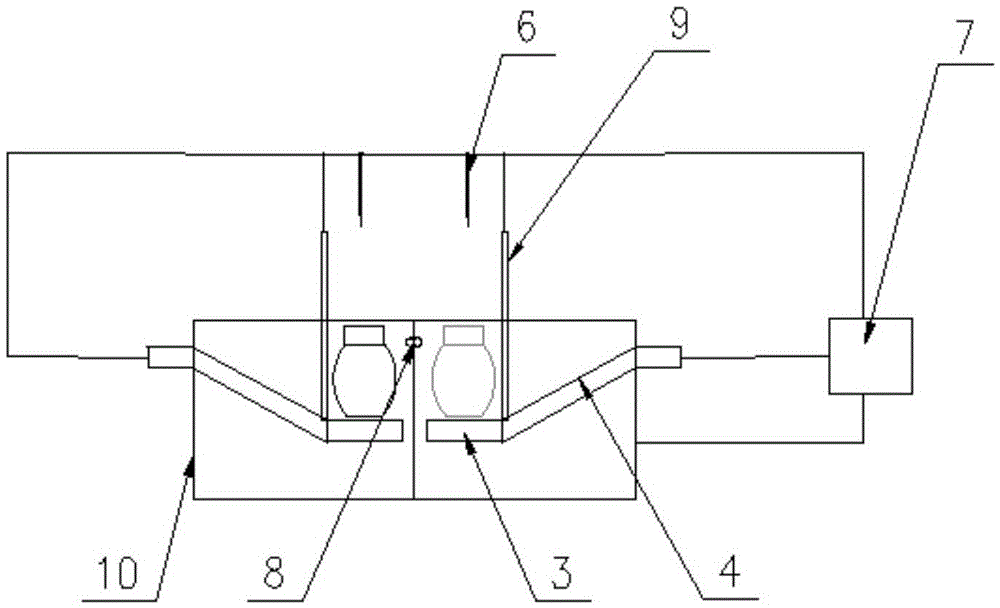

[0022] Such as figure 1 and 2 As shown, a wine jar leak detection device includes a water tank 10, and the tank 10 is provided with an inlet conveying device 1, a genuine product conveying device 2 and a defective product conveying device 4, and several water spray devices are arranged above the altar conveying device 1 5. The water spray device 5 is connected with the control system 7, and a sensor 8 is set near the corresponding altar-incoming conveying device 1. Through the sensor 8, the control system 7 controls the water-spraying device 5 to spray water; The inspection platform 3 is at the intersection of the defective product conveying device 4, the altar feeding conveying device 1, the genuine product conveying device 2 and the defective product conveying device 4 all adopt a conveyor belt conveying device, and the detecting platform 3 and the defective product detecting device 4 are integrated into a conveyor belt for conveying device, the detection platform 3 and the...

Embodiment 2

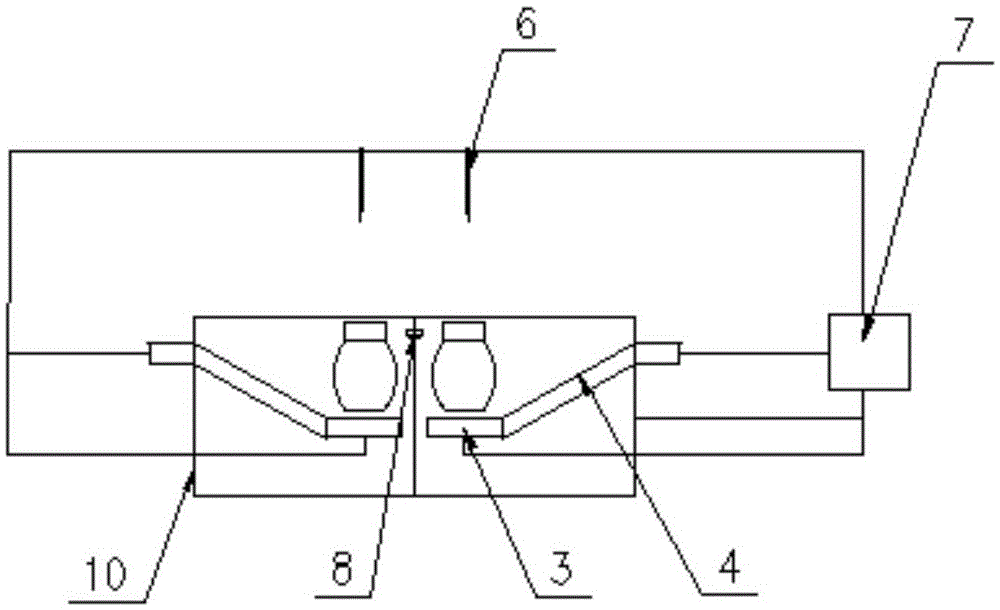

[0025] Such as figure 1 and 3 As shown in and 4, compared with embodiment 1, a baffle device is not provided at the junction of the detection platform 3 and the defective product conveying device 4; Roller device, the arrangement direction of several horizontal rollers is consistent with the 4 directions of the defective product conveying device, and the arrangement direction of several vertical rollers is consistent with the 2 directions of the genuine product conveying device; there is a link transmission device between the horizontal rollers, controlled by the control system 7 control, so that the detection platform 3 can be controlled by the control system 7 to transport the upper wine jar to the defective product conveying device 4.

[0026] Working principle: Place the wine jar on the conveying device 1 for entering the jar. During the conveying process, the sensor 8 is triggered, the water spray device 5 injects water into the wine jar, and the wine jar is transported ...

Embodiment 3

[0028] Compared with Embodiment 2, the horizontal roller of the detection platform 3 is connected with the defective product conveying device 4 through a link transmission device, and the control system 7 can control the simultaneous operation of the defective product conveying device 4 and the horizontal roller of the detection platform 3; the detection platform The vertical rollers of 3 are connected to the authentic conveying device 2 through a link transmission device, and the control system 7 can control the authentic conveying device 2 and the vertical rollers of the detection platform 3 to operate simultaneously.

[0029] Working principle: Place the wine jar on the conveying device 1 for entering the jar. During the conveying process, the sensor 8 is triggered, the water spray device 5 injects water into the wine jar, and the wine jar is transported to the detection platform 3. Through the sensor 8, the control system 7 The electrode detection needle of the control dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com