High voltage lead angle error influence testing device and testing method thereof

A high-voltage lead wire and angle error technology, which is applied in the direction of measuring devices, instruments, and measuring electrical variables, can solve problems such as difficulties in on-site verification, poor response characteristics of transformers, and difficulty in satisfying fast and accurate actions of relay protection, etc. Difficulty, operability improvement effect

Inactive Publication Date: 2016-05-25

STATE GRID CORP OF CHINA +1

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Electric field simulation shows that for a 1000kV CVT, the capacitive current flowing from the high-voltage arm of the voltage divider into the ground can reach 20mA, causing significant measurement errors

Measures are usually taken to increase the main capacitance of the voltage divider to reduce the influence of stray currents, but even if the capacitance is increased to 10000pf, the accuracy level of UHV CVT is still difficult t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

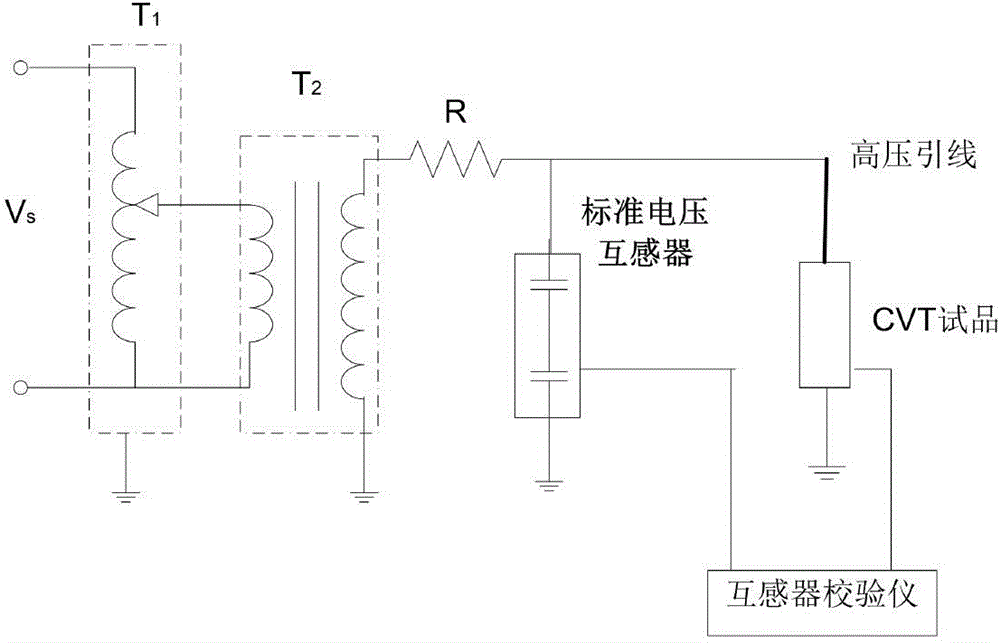

The invention relates to a high voltage lead angle error influence testing device and a testing method thereof. The device comprises a voltage regulator, a test transformer, a standard transformer, an equipotential shielded capacitor voltage transformer (CVT) test sample and a high voltage lead, wherein the primary side of the test transformer is connected with the voltage regulator, one end of the secondary side is grounded, and the other end of the secondary side is connected with one end of a current limiting resistor R; the other end of the current limiting resistor R is respectively connected with the primary side of the standard voltage transformer and the primary side of the equipotential shielded capacitor voltage transformer test sample; the secondary side of the standard voltage transformer and the secondary side of the equipotential shielded capacitor voltage transformer test sample are both connected with a transformer calibrator; and an angle is formed between the high voltage lead and the axis of the equipotential shielded capacitor voltage transformer test sample. Conditions of different high voltage lead connection modes can be simulated successfully, the accuracy of the CVT in the conditions is verified to still achieve requirements of a high-precision accuracy grade, and in the above conditions, the generated error changes are smaller than those of a CVT with a traditional structure.

Description

technical field [0001] The invention relates to a power system transformer device and a method thereof, in particular to a high-voltage lead wire angle error influence test device and a test method thereof. Background technique [0002] With the engineering application of UHV (AC 1000kV and above) transmission technology, the accurate measurement of UHV grid voltage has become a key technical problem to be studied and solved. The power frequency high voltage measurement devices widely used in the power system mainly include electromagnetic voltage transformers and capacitive voltage transformers (both of which are passive voltage measurement systems), which can basically meet the requirements of 500kV and below voltage level voltage measurement and Requirements for relay protection. Photoelectric voltage transformers and electronic voltage transformers (both of which are active voltage measurement systems) are still in the process of research and development and trial opera...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R35/02

Inventor 查鲲鹏董巍李志麒高冲

Owner STATE GRID CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com