Test fixture used for three-directional vibration test of thin and long elbow pipe and test method of test fixture

A test fixture and vibration test technology, used in vibration testing, machine/structural component testing, measuring devices, etc., can solve the problems of inability to conduct tests, reduce the utilization rate of shaking tables, etc., to save test costs, improve work efficiency, Eliminate the effect of extra load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

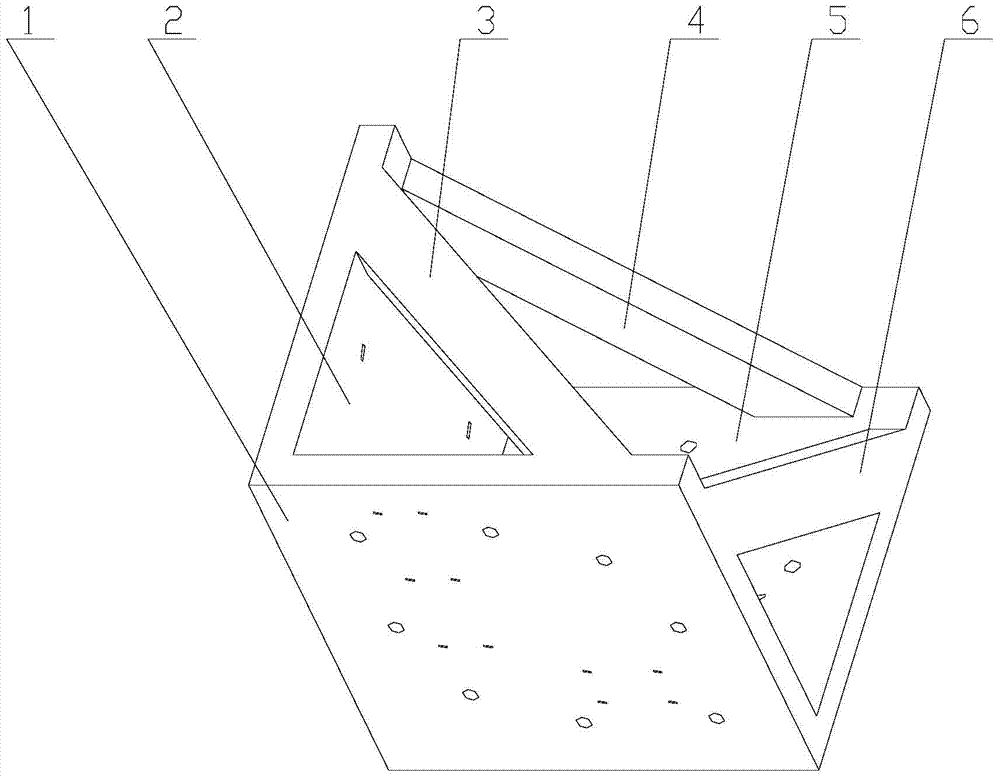

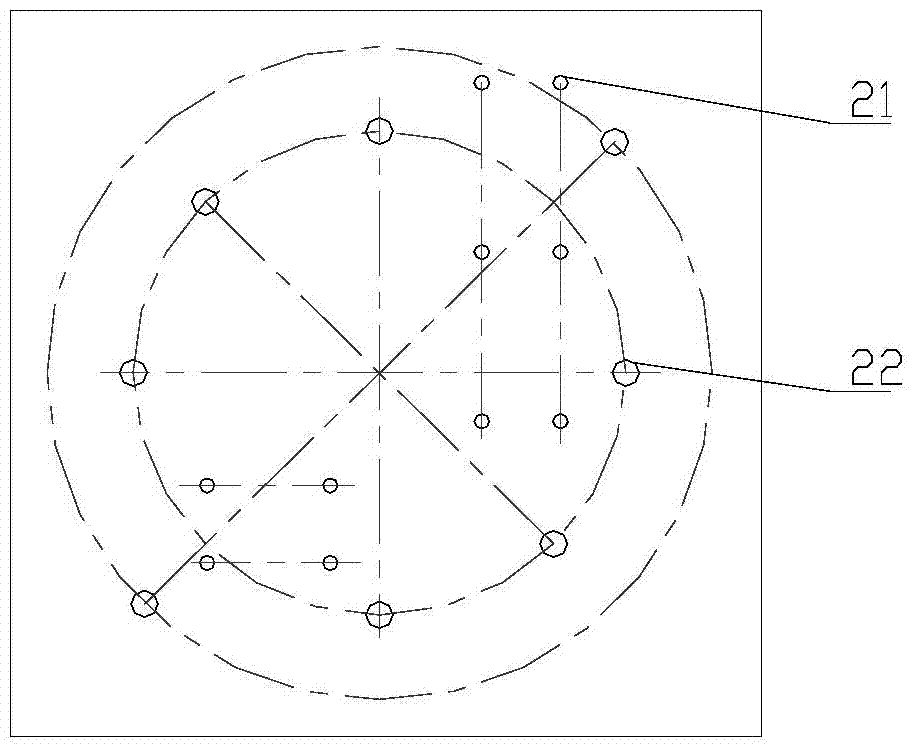

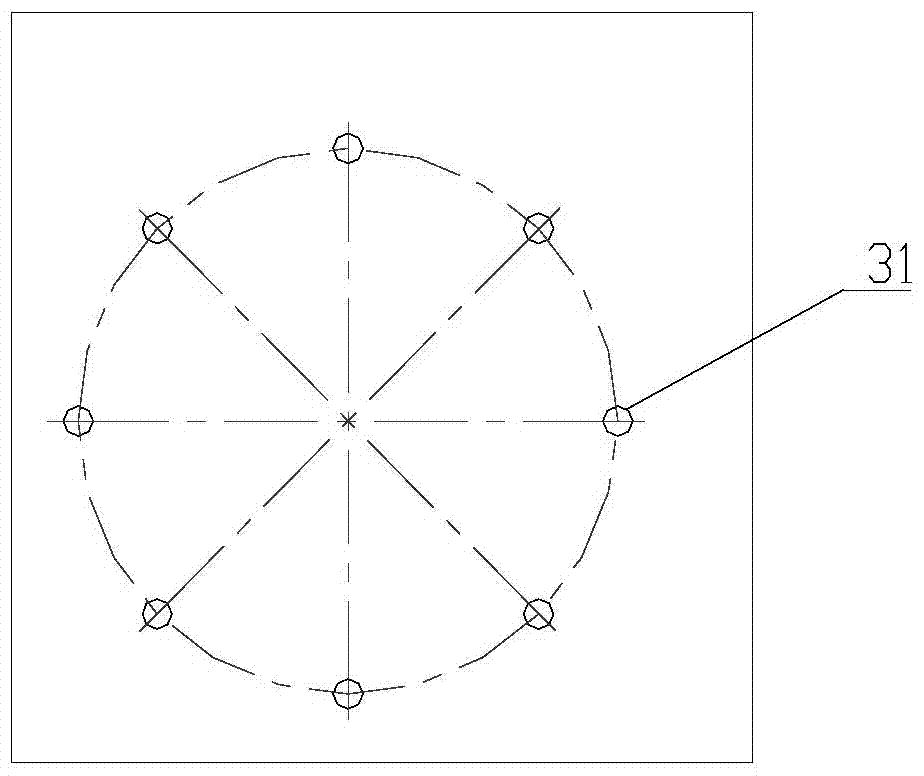

[0029] Please also see Figure 1 to Figure 5 .

[0030] This embodiment provides a test fixture for the three-way vibration test of a slender bent pipe, including an X-direction mounting plate, a Y-direction mounting plate and a Z-direction mounting plate, and the X-direction mounting plate, Y-direction mounting plate and Z-direction mounting plate Two of the mounting plates are vertically connected to each other to form three orthogonal planes; between the X-direction mounting plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com