Three-dimensional vector beam and generation method and apparatus thereof

A three-dimensional vector and light beam technology, which is applied in optics, optical components, instruments, etc., can solve the problems of increased inconvenience and fixed vector beam polarization distribution, and achieves the effects of simple structure, convenient operation and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

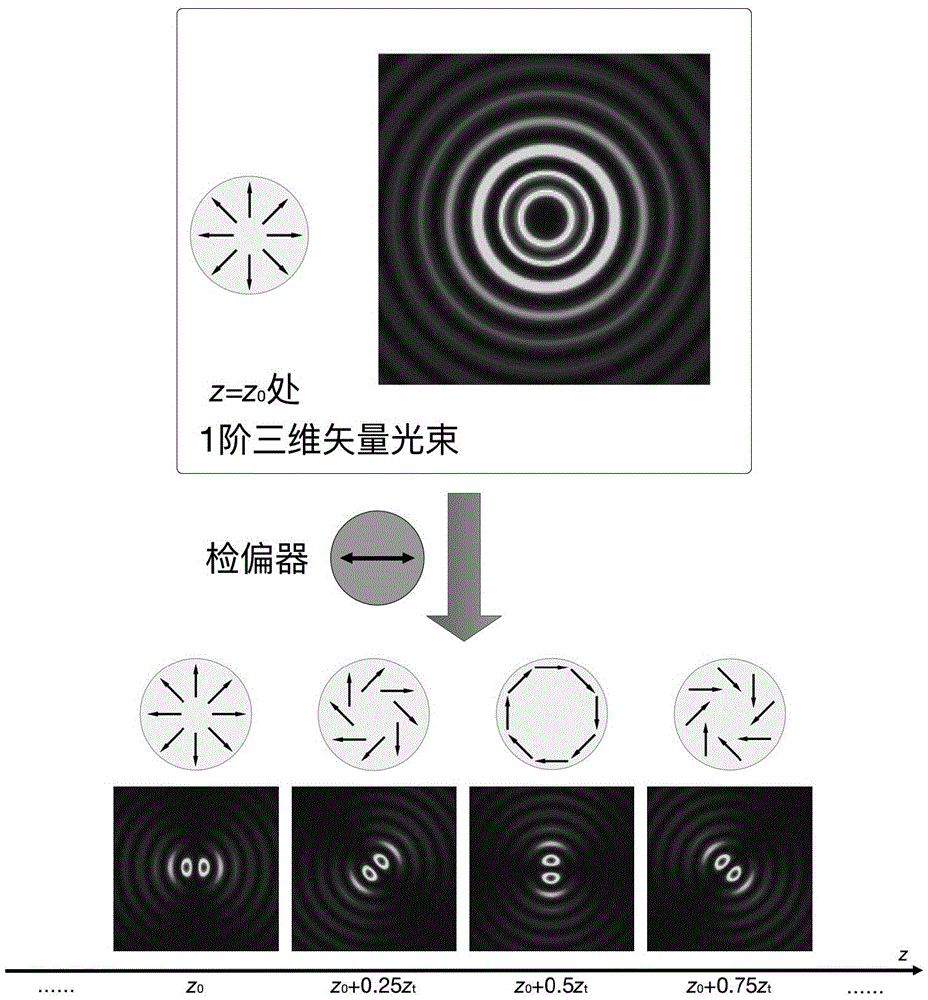

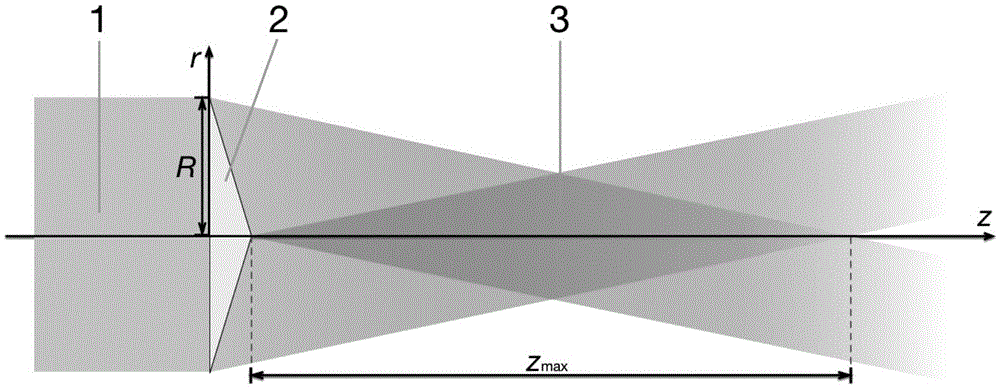

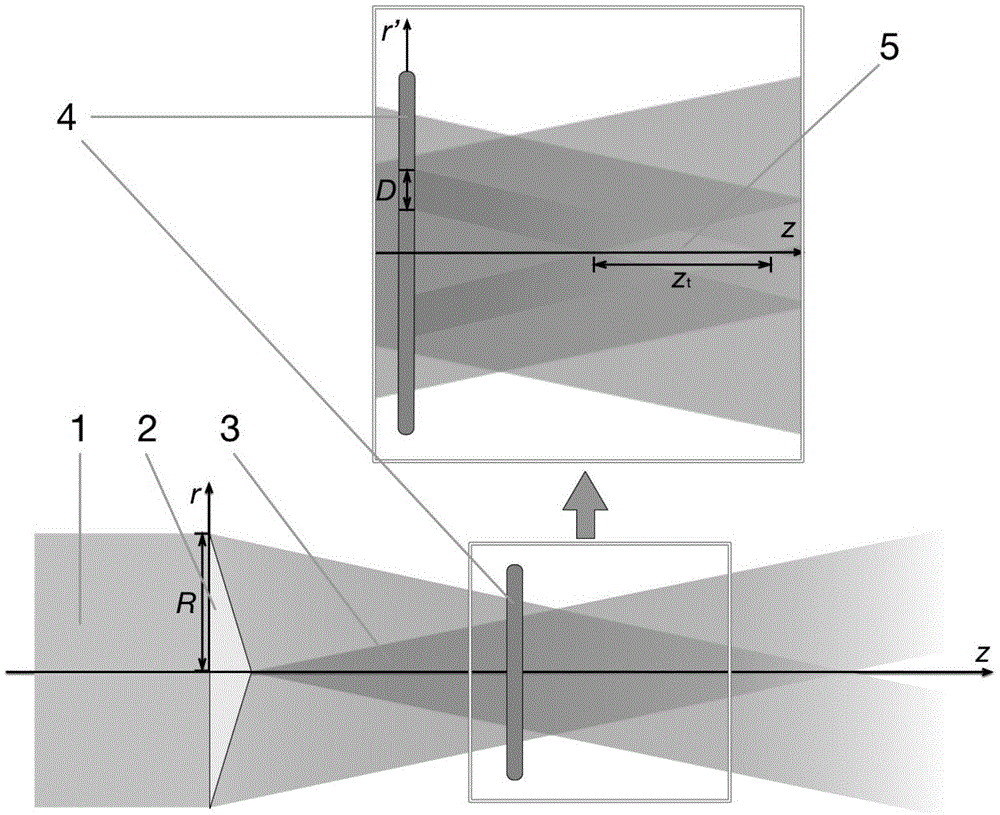

[0042] Embodiment 1: Generation of first-order three-dimensional vector beams.

[0043] will be like Figure 4 The shown holographic grating after superimposing the axicon and the first-order spiral phase plate, and the holographic grating after superimposing the radial periodic phase and the second-order spiral phase plate are respectively loaded on the image 3 Two liquid crystal spatial light modulators in the shown setup. Turn on the laser light source, fix the CCD camera on the optical rail placed along the optical axis, and measure the three-dimensional vector beam at the initial position, 1 / 4 space period, 1 / 2 space period and 3 / 4 space period Such as Figure 5 shown in column 1. A rotatable polarizer is added in front of the CCD camera to detect the polarization state of the three-dimensional vector beam. When the polarizer is placed horizontally, 45° and vertically, the light spots received by the CCD camera are as follows: Figure 5 As shown in the last three co...

Embodiment 2

[0044] Embodiment 2: Generation of second-order three-dimensional vector beams.

[0045] will be like Image 6 The shown holographic grating after superimposing the axicon and the 2nd-order spiral phase plate, and the holographic grating after superimposing the radial periodic phase and the 4th-order spiral phase plate are respectively loaded on the image 3 Two liquid crystal spatial light modulators in the shown setup. Turn on the laser light source, fix the CCD camera on the optical rail placed along the optical axis, and measure the three-dimensional vector beam at the initial position, 1 / 4 space period, 1 / 2 space period and 3 / 4 space period Such as Figure 7 shown in column 1. A rotatable polarizer is added in front of the CCD camera to detect the polarization state of the three-dimensional vector beam. When the polarizer is placed horizontally, 45° and vertically, the light spots received by the CCD camera are as follows: Figure 7 As shown in the last three columns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com