Transverse vibration clamp adjustable in gravity center and angle

A lateral vibration, arbitrary angle technology, used in manufacturing tools, workpiece clamping devices, measuring devices, etc., can solve the problems of low test frequency, high cost, and overall bulky equipment, and achieve convenient torque control, versatility and stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited thereto.

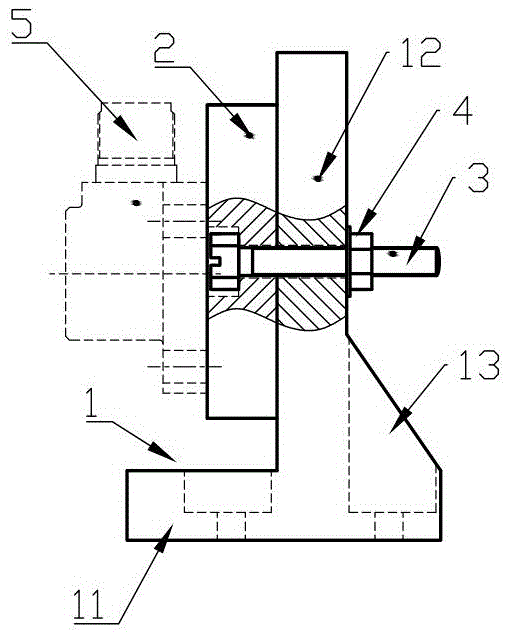

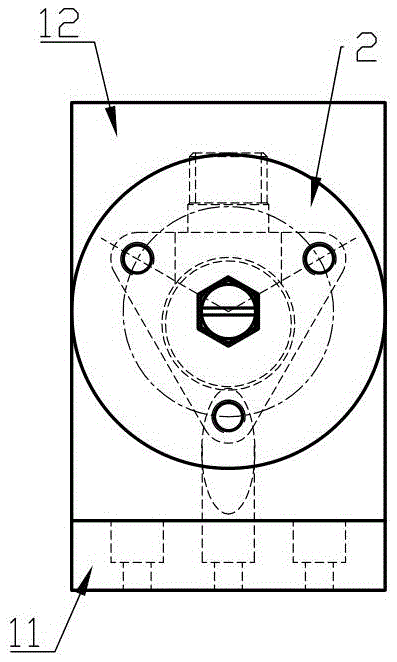

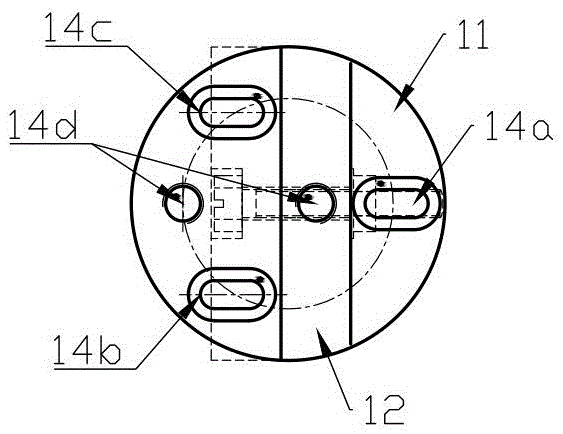

[0014] like Figure 1 to Figure 3 As shown, the transverse vibration fixture can be seen in general: it is composed of a base 1, an adapter plate 2, and matching bolts 3 and nuts 4. The base 1 is an inverted T-shaped structure in side view and the round bottom surface 1 of the base There are sensor mounting holes 14d and three parallel vibrating table mounting waist holes (14a, 14b, 14c) distributed in a triangular shape, the vertical wall surface 12 of the base 1 is perpendicular to the circular bottom surface 11, and the adapter plate 2 is passed through the bolt 3. The nut 4 is connected to the vertical wall surface 12 and can be rotated and adjusted by 360° (through the tightness of the elastic bolt and the nut), and the measured sensor 5 is fixedly connected to the surface of the connecting plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com