Steel strip reeling machine

A steel strip coil and reel technology, applied in the direction of electromechanical devices, mechanical energy control, electrical components, etc., can solve the problems of poor transmission stability, small application range, single transmission structure, etc., achieve adjustable coiling width, and reduce maintenance difficulty , good transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

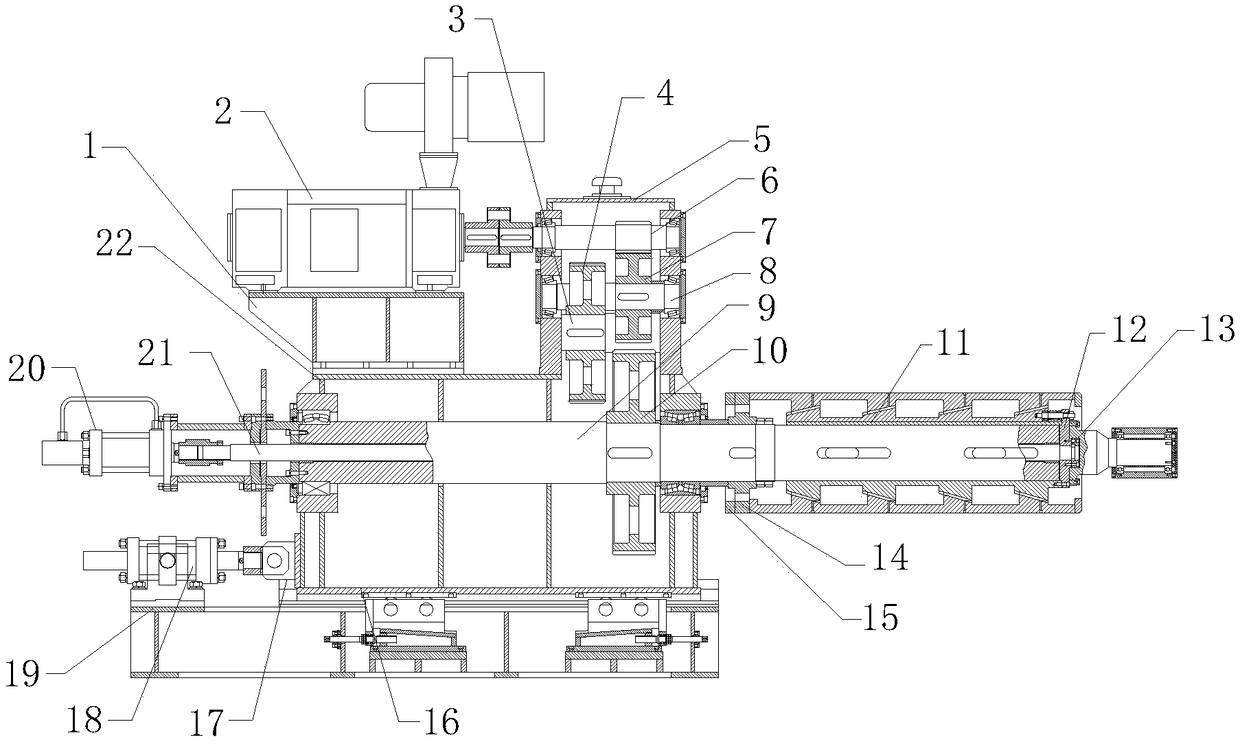

[0024] Specific implementation method: when in use, the staff runs the DC motor 2, and then the DC motor 2 drives the gear shaft 2 6 to rotate in the gearbox 5, the gear shaft 2 6 drives the gear 2 7 to rotate, and the gear 2 7 drives the gear shaft 3 8 Rotate, gear shaft three 8 drives gear one 4 to rotate, gear one 4 drives gear shaft one 3 to rotate, gear shaft one 3 drives gear three 10 to rotate, gear three 10 drives main shaft 9 to rotate, thereby realizes the purpose of main shaft 9 independent rotations.

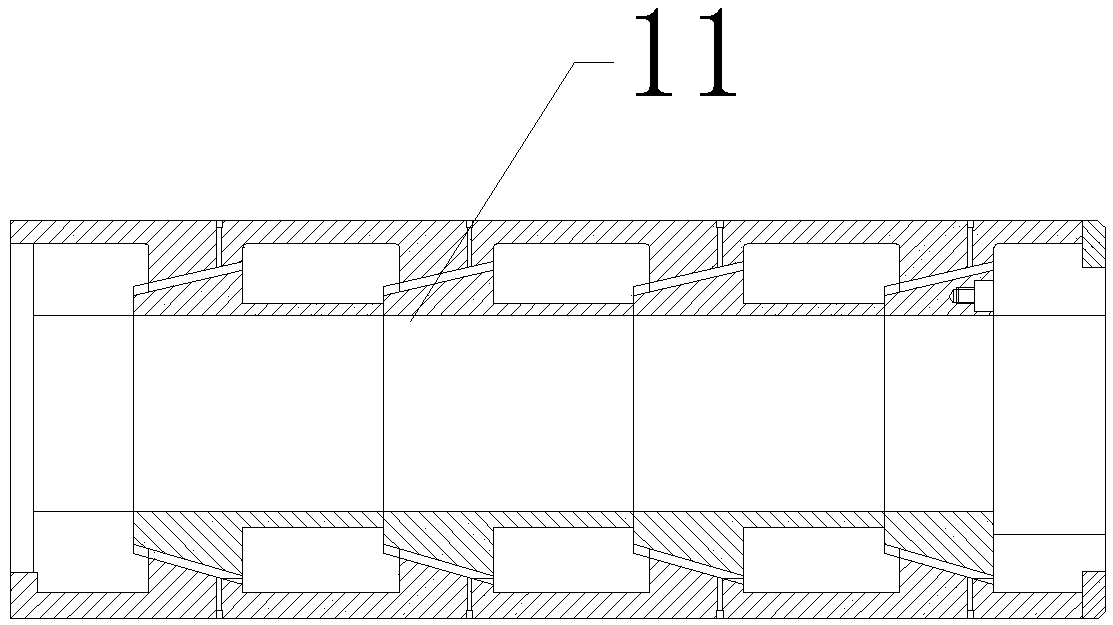

[0025] When the length of the telescopic sleeve 11 needs to be shortened, the staff makes the hydraulic cylinder one 21 shrink, and then the hydraulic cylinder one 21 shrinks to drive the push-pull rod 22 to move to the left in the main shaft 9, and then the push-pull rod 22 drives the retaining sleeve 13 to move to the left. The sleeve 13 squeezes the telescopic sleeve 11 through the baffle plate 12, because the baffle plate 15 is installed on the annular side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com