Lifting appliance for lifting tundishes

A technology of tundish and spreader, which is applied in the field of metallurgy, can solve problems such as rollover and easy overflow of molten steel, and achieve the effects of convenient operation, small uncoupling space, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below.

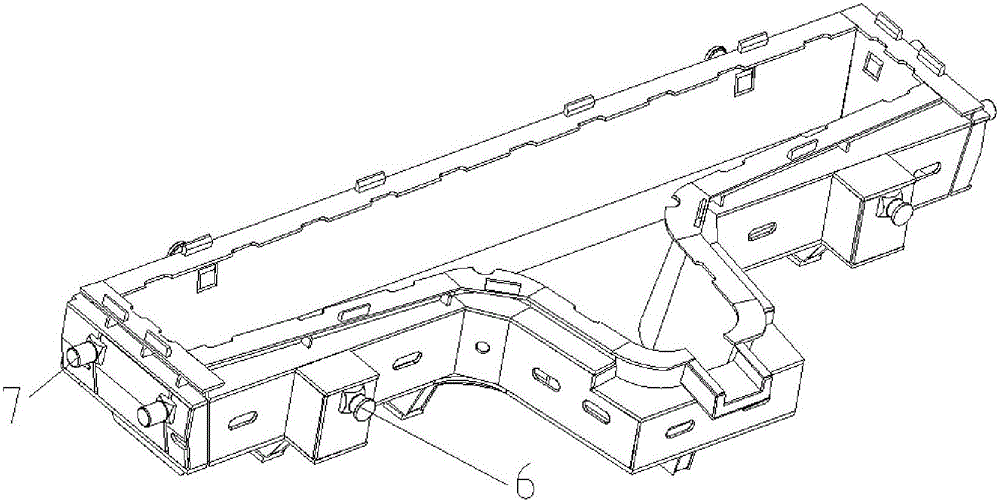

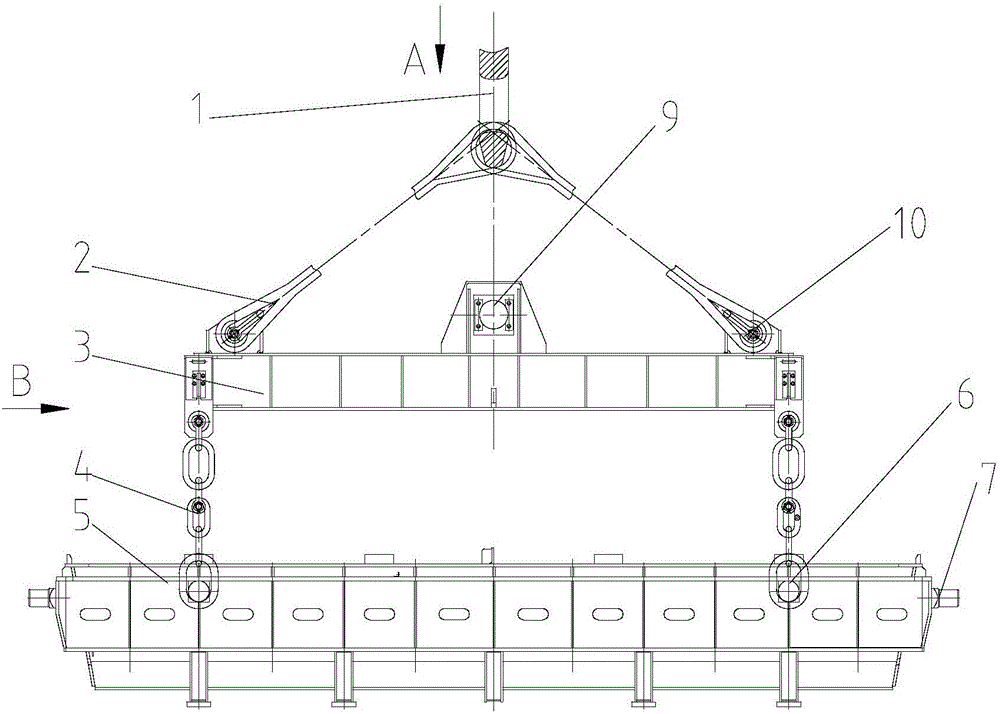

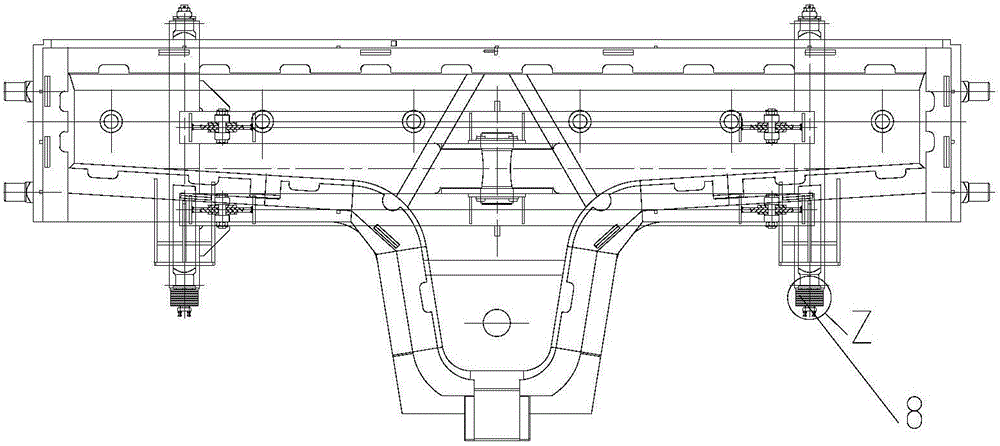

[0039] Such as Figure 1-7 As shown, a spreader for lifting a tundish includes a sling 2, a spreader beam 3, a long lifting ring 4, a counterweight 8, a main shaft 9 for lifting an empty bag and lifting lugs 10 for lifting a full bag,

[0040] The four corners of the lifting lug 10 and the upper surface of the spreader beam 3 are welded with full package,

[0041] The middle part of the spreader beam 3 is provided with a through hole, and the empty bag lifting main shaft 9 is fixedly connected with the through hole through a transition fit mode, and the shaft end of the empty bag lifting main shaft 9 is provided with a shaft end baffle,

[0042] One end of the sling 2 is fixedly connected with the full bag lifting lug 10 or the empty bag lifting main shaft 9 through a shackle,

[0043] The four corners of the bottom side of the spreader beam 3 are respectively provided with a through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com