Lifting unit for lifting and lowering a container in a container treatment assembly

A lifting unit, processing equipment technology, applied in liquid handling, transportation and packaging, packaging, etc., can solve problems such as high energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] A preferred exemplary embodiment is subsequently described with reference to the drawings. Identical, similar or identically acting components are identified here with the same reference symbols. In order to avoid redundant description, repeated descriptions of these components are partially omitted in the following description.

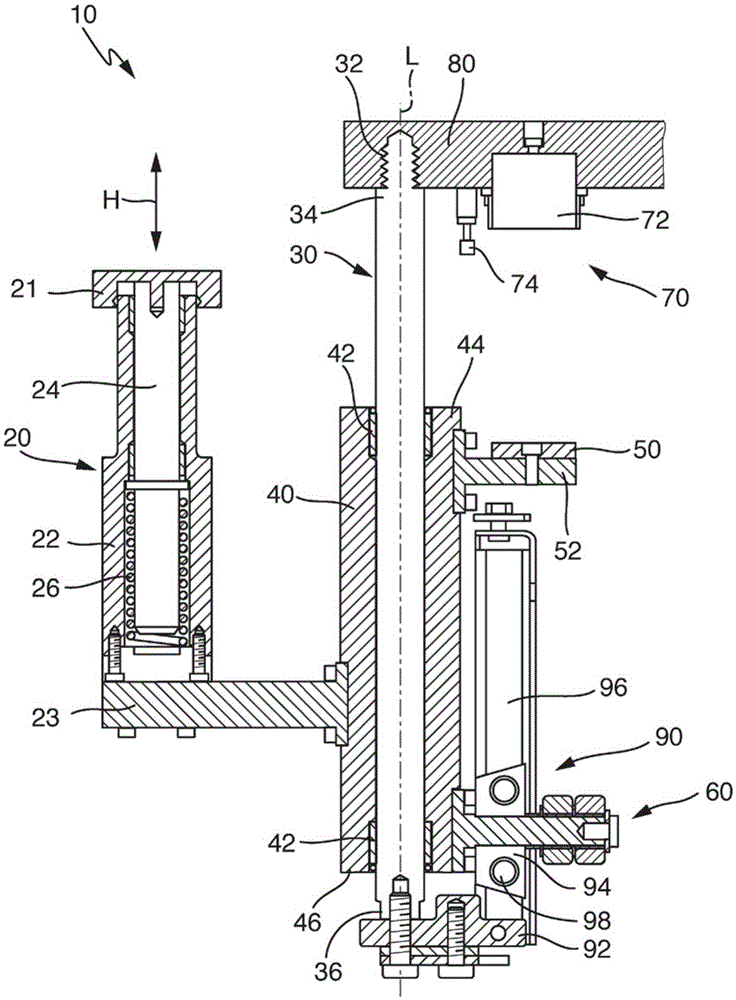

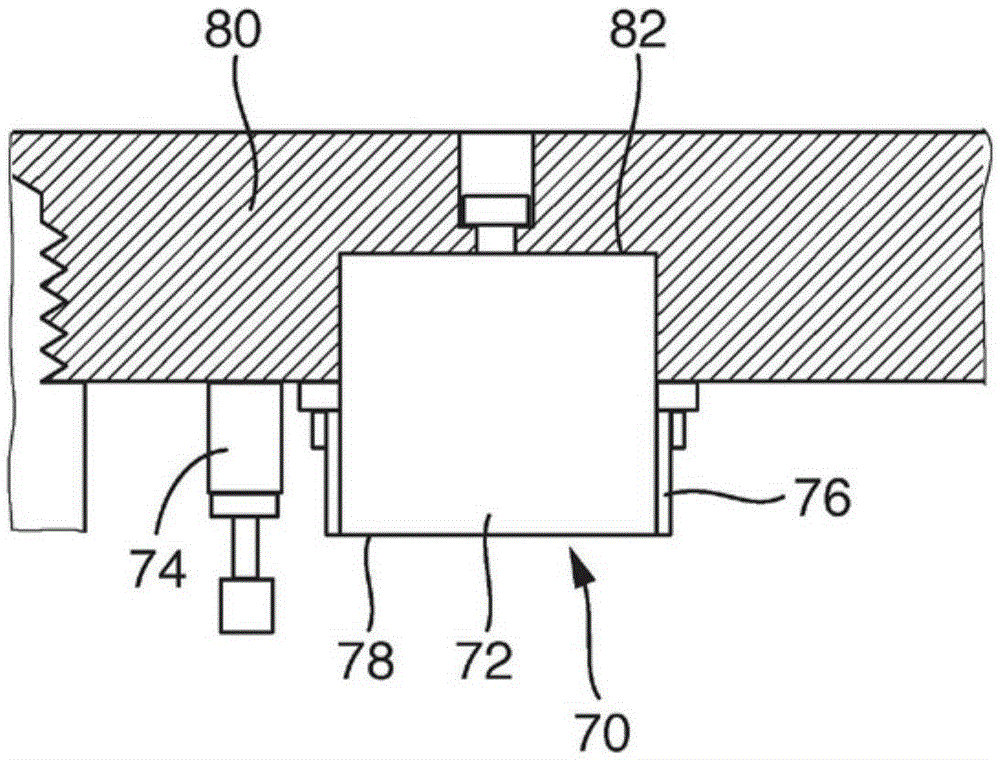

[0052] figure 1 A lifting unit 10 is shown, which can lift and lower containers in a container processing plant. For this purpose, the lifting unit 10 has a container holder 20 on which the containers can be arranged. The container holder 20 is guided via a bearing 40 onto the first guide 30 and can be raised and lowered via a lifting device 60 . For the corresponding container handling, a locking device 70 is provided on the support plate 80 of the swivel part, which locks the armature 50 arranged on the bearing 40 so that the container holding device 20 is held in a predetermined position.

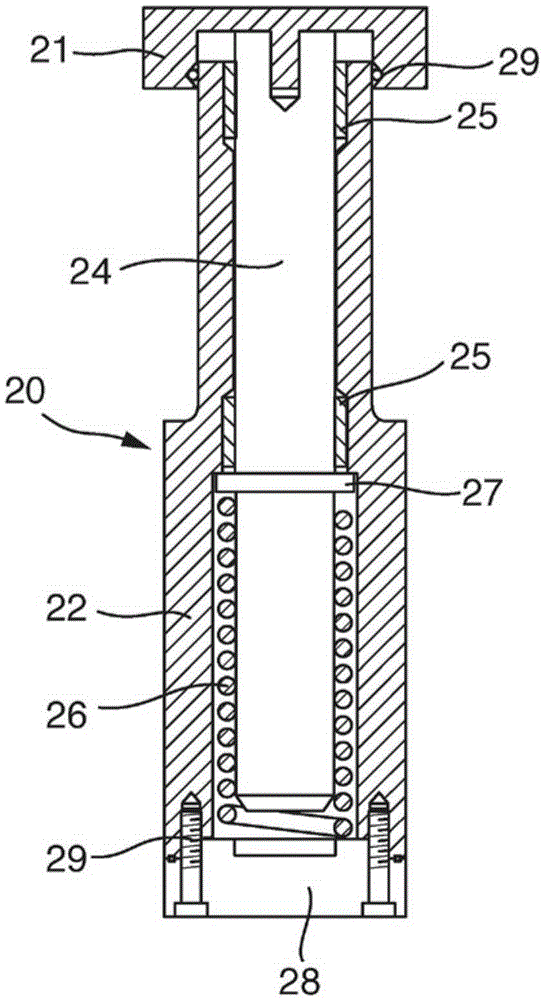

[0053] figure 1 and 3 The container holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com