High-speed cotton-guiding device for carding machine

A carding machine and cotton guiding technology, which is applied in the direction of deburring device, textile and papermaking, fiber processing, etc. The effect of less frequency, less vibration and impact, and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

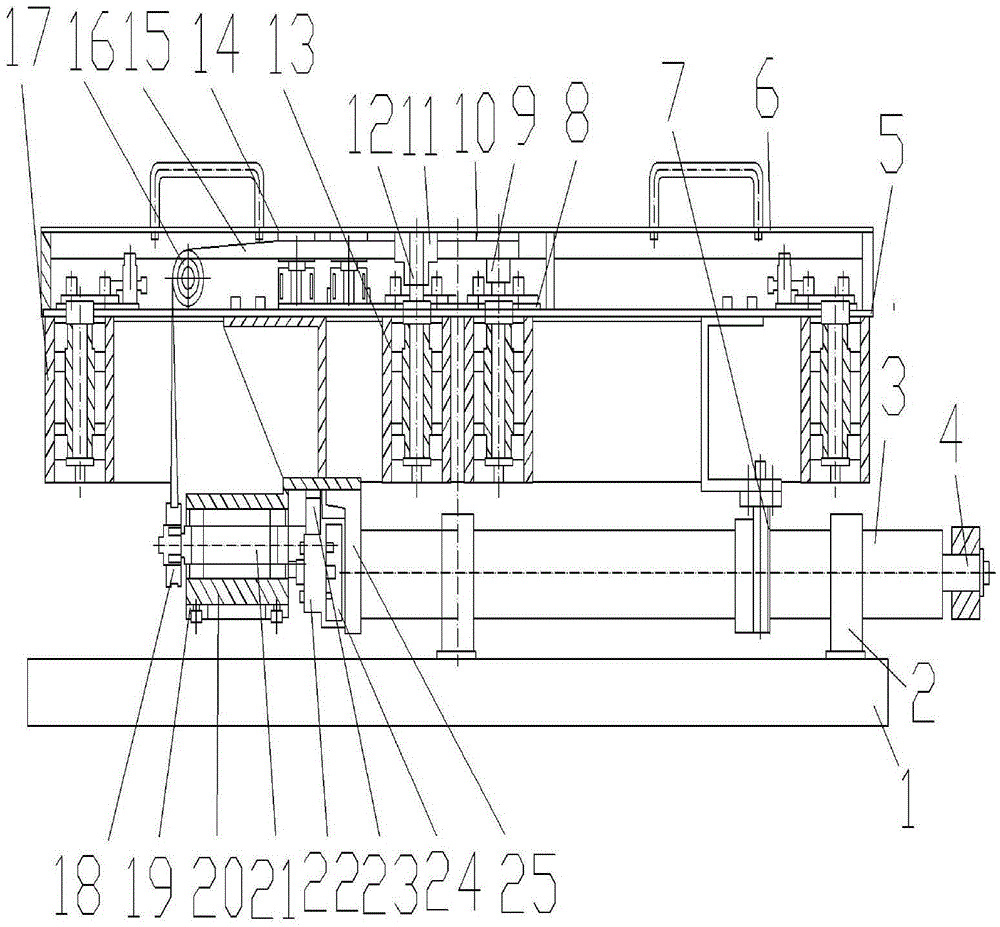

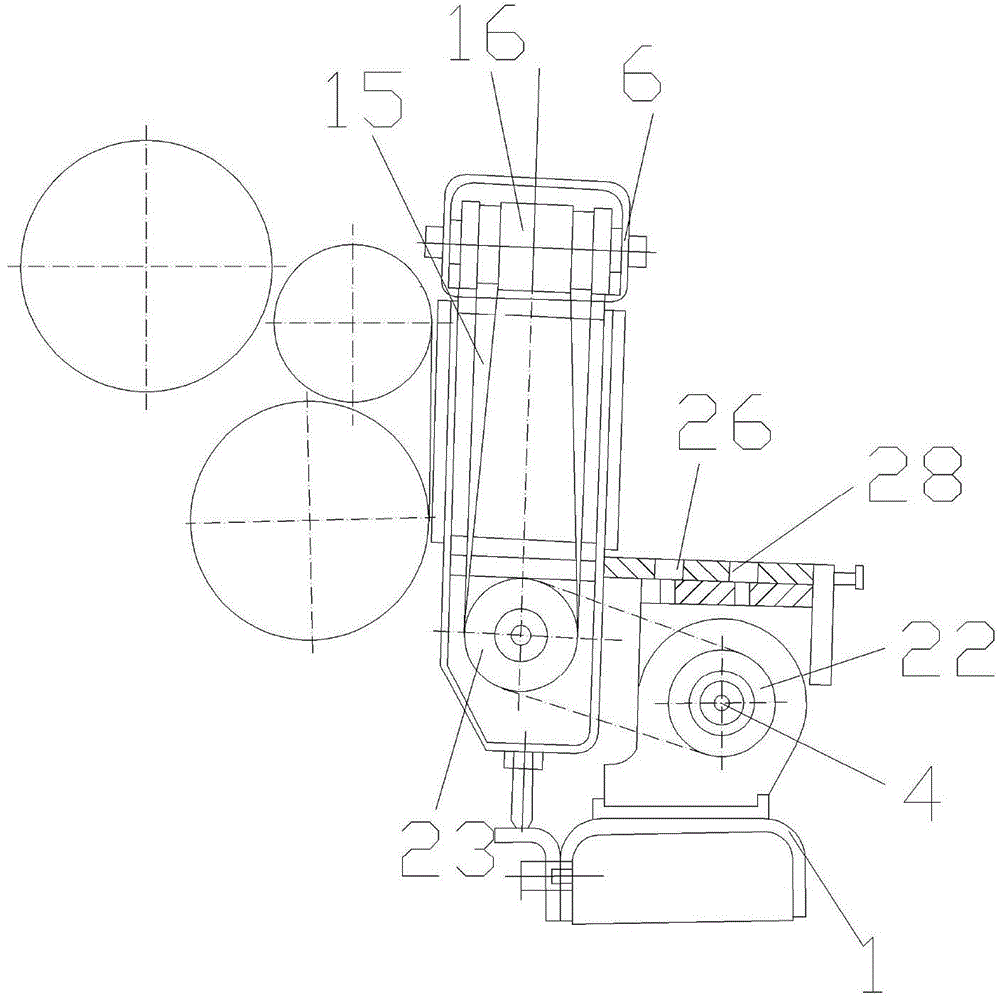

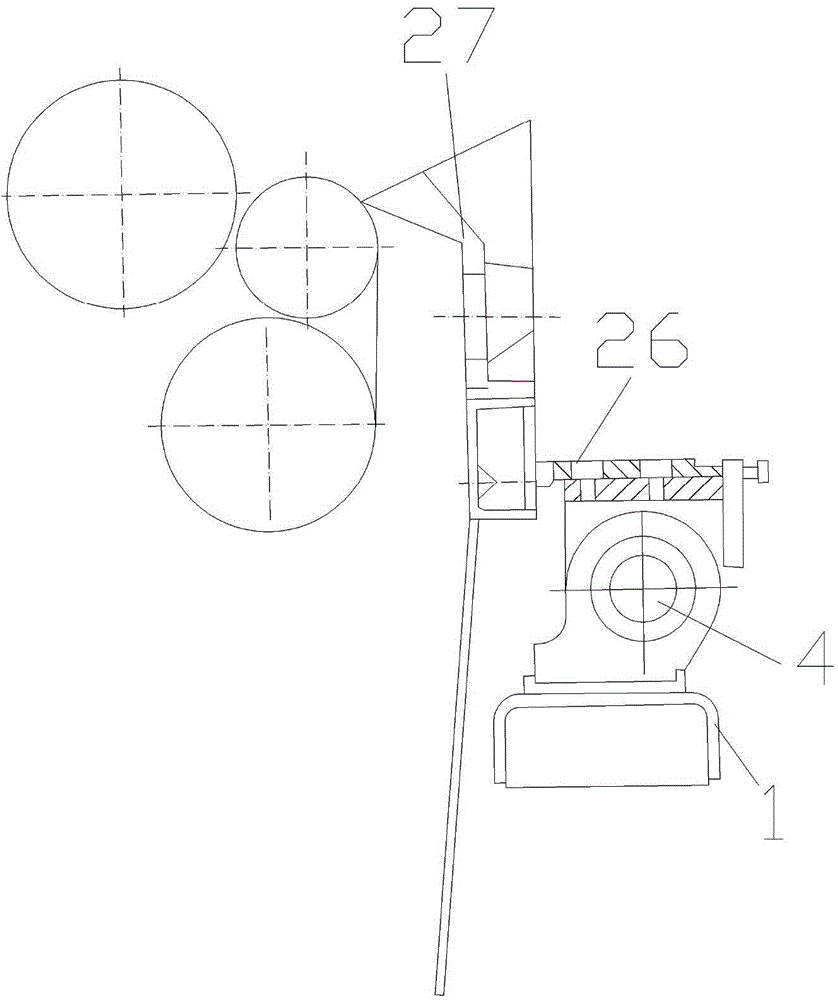

[0016] Such as figure 1 As shown, a high-speed cotton guiding device for a carding machine includes a beam 1, a first support 2, a shaft sleeve 3, a main shaft 4, a first apron 5, a casing 6, a second support 7, and a first apron Guide wheel 8, first shaft 9, first pulley 10, second pulley 11, second shaft 12, second apron guide wheel 13, tension pulley 14, belt 15, steering wheel 16, second apron 17, Bearing 19, bearing seat 20, third support 25, screw 26 and timing belt 27, the first support 2 is installed on the beam 1, the shaft sleeve 3 is connected to the first support 2, and the main shaft 4 is connected to the shaft sleeve 3 , the casing 6 is fixed above the second support 7 by screws 26, the first apron guide wheel 8 and the second apron guide wheel 13 are respectively equipped with the first apron 5 and the second apron 17, the first shaft 9 and the second shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com