Sewing machine

A sewing machine and sewing technology, applied in the field of sewing machines, can solve the problems of finger pricking, difficult promotion, work-related injuries, etc., and achieve the effect of ensuring smooth progress and preventing overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

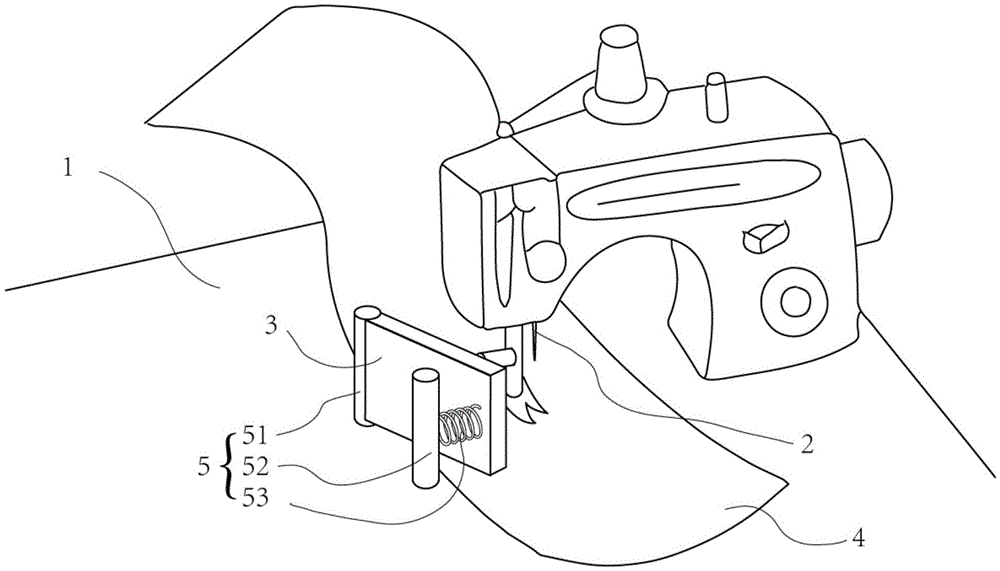

[0028] The first embodiment of the present invention provides a sewing machine, see figure 1 As shown, it includes a sewing table and a sewing needle arranged on the sewing table, and the sewing needle can reciprocate in the height direction to perform sewing work. The sewing machine also includes a blocking plate positioned on one side of the sewing needle and a supporting device connecting the blocking plate and the sewing table. The blocking plate is arranged on the sewing table through the supporting device, and the blocking plate can move radially along the table top of the sewing table, and there is a gap reserved between the blocking plate and the sewing table for passing the fabric to be sewn.

[0029] Wherein, the supporting device includes a rotating shaft fixedly connected with the sewing table, the rotating shaft can rotate along its own axis, one side of the blocking plate is connected with the rotating shaft, and the blocking plate can rotate with the rotating sh...

Embodiment approach 2

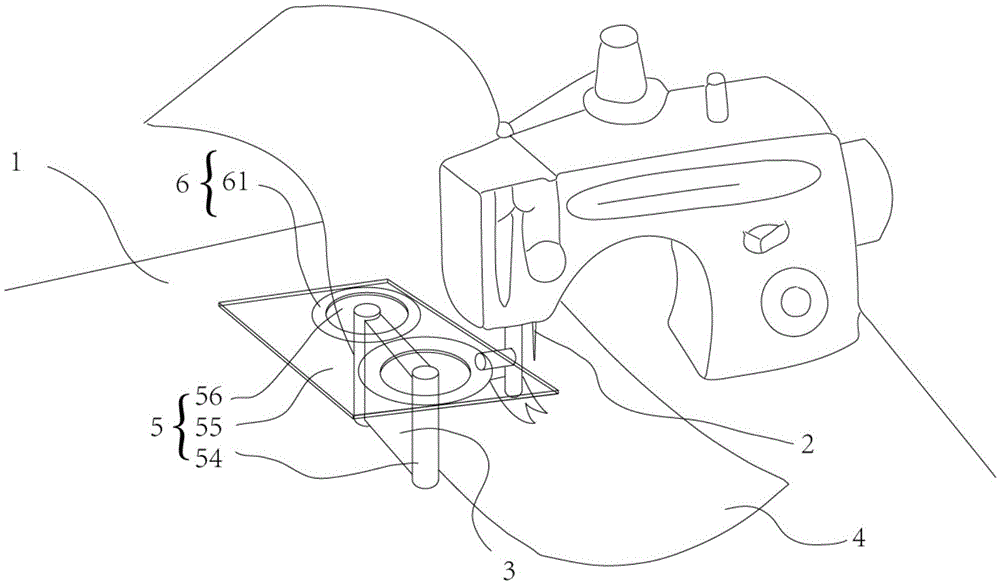

[0033] A second embodiment of the present invention provides a sewing machine, see figure 2 and image 3 As shown, it includes a sewing table and a sewing needle arranged on the sewing table, and the sewing needle can reciprocate in the height direction to perform sewing work. The sewing machine also includes a blocking plate positioned on one side of the sewing needle and a supporting device connecting the blocking plate and the sewing table. The blocking plate is arranged on the sewing table through the supporting device, and the blocking plate can move radially along the table top of the sewing table, and there is a gap reserved between the blocking plate and the sewing table for passing the fabric to be sewn.

[0034]In this embodiment, the supporting device includes at least two translation shafts connected to the blocking plate, a limit assembly connected to the translation shafts, and a first fixing plate arranged at intervals above the sewing table. Wherein, the fir...

Embodiment approach 3

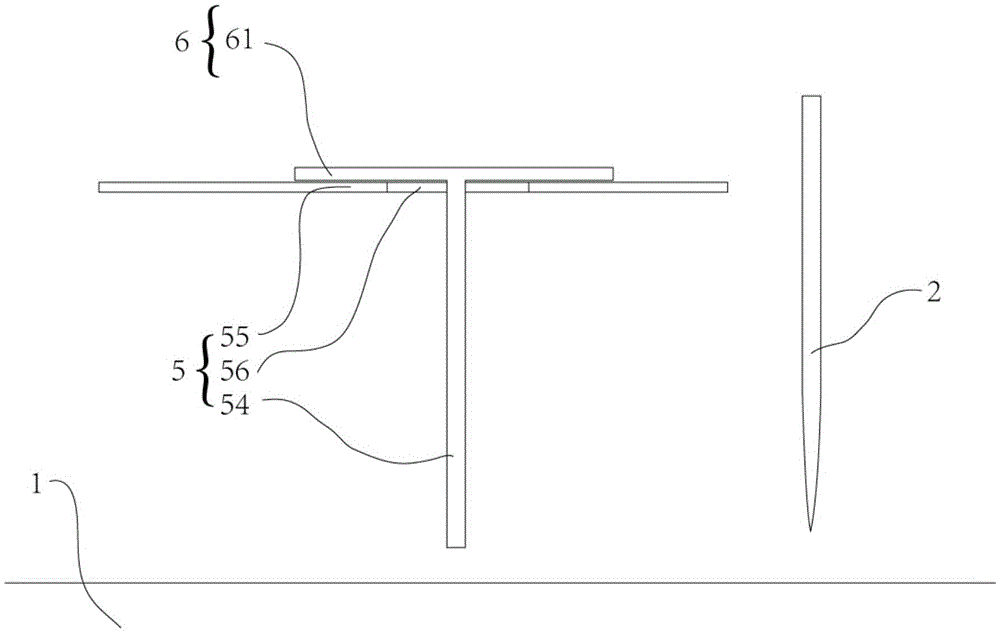

[0038] The third embodiment of the present invention provides a sewing machine, the third embodiment is a further improvement of the second embodiment, the main improvement is that, in the third embodiment of the present invention, see Figure 5 As shown, the supporting device further includes a second fixing plate arranged at intervals above the first fixing plate, and the second fixing plate is provided with second through holes having the same number as the first through holes and one-to-one correspondence. The support device also includes a second positioning piece arranged at any end of the second through hole, the diameter of the second positioning piece is larger than the diameter of the second through hole, and the translation axis passes through the second through hole and is connected with the second positioning piece. The double through holes arranged at intervals and multiple sets of positioning pieces can stabilize the center of gravity of the blocking plate, furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com