Function and test integrated driving wheel torque calibration method

A calibration method and the technology of the driving wheel, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problem that the torque of the driving wheel cannot be accurately and reliably tested, and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Function and test integrated drive wheel torque calibration method, the method utilizes function and test integrated drive wheel,

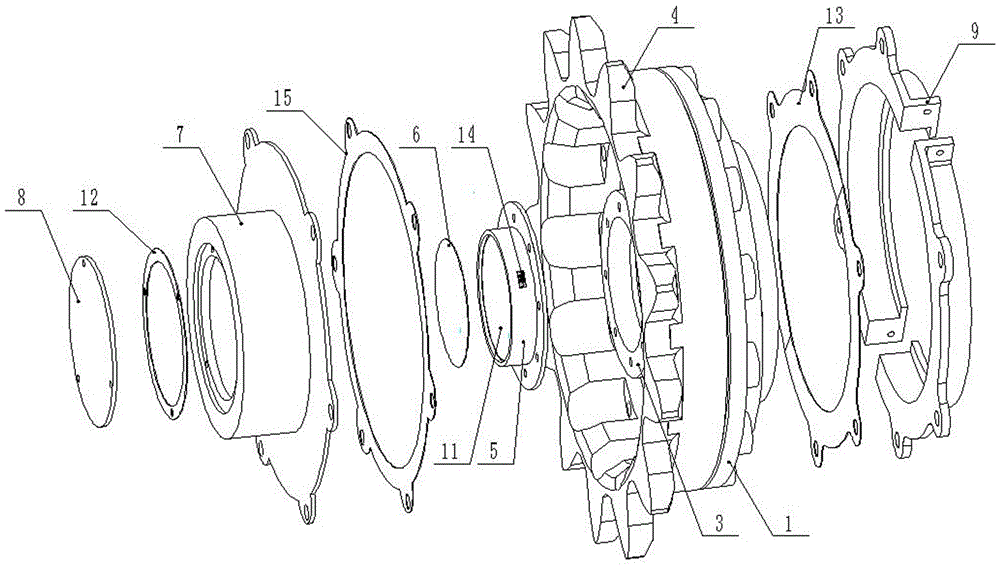

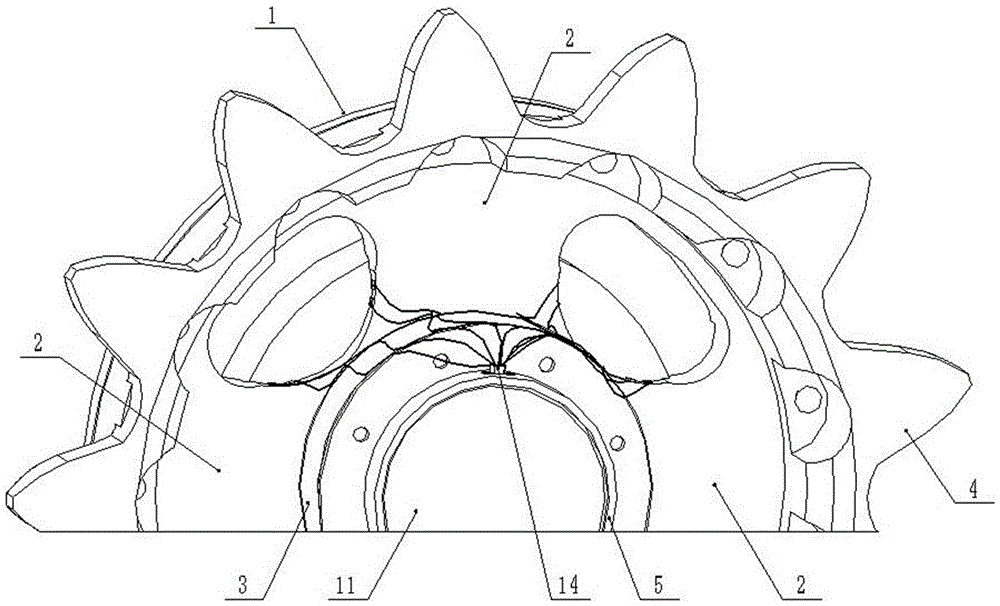

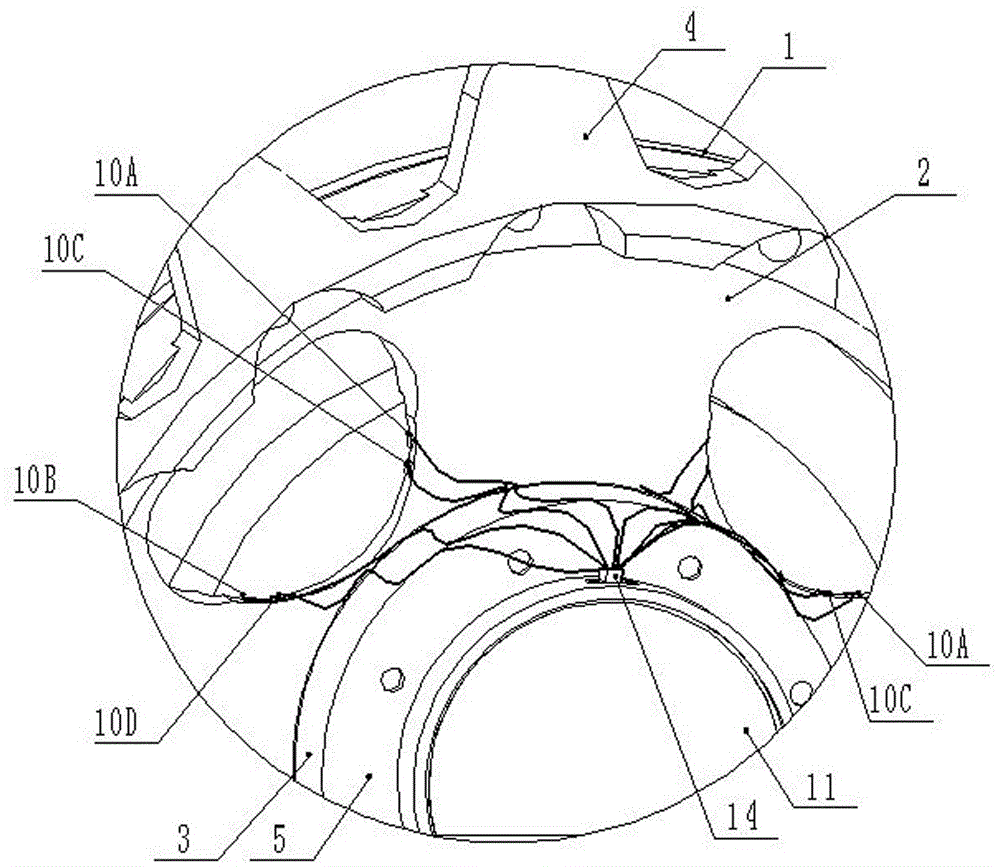

[0030] The function and test integrated driving wheel includes a hub formed by connecting a flange 1, a number of spokes 2, and a connecting disc 3 from the outside to the inside, and the outer edge of the flange 1 close to the outer side of the vehicle is connected with a driving wheel chainring 4 , there are at least m spokes 2 evenly distributed on the hub, where m is a natural number and ≧3, and one end of the connecting plate 3 close to the outside of the vehicle is sequentially provided with a cylinder 5 and a cylinder cover 6 for closing the inner circle of the cylinder 5 One end of the flange 1 close to the outside of the vehicle is sequentially provided with a front metal cover ring 7 for covering the cylinder body 5 and a front metal end cap 8 for closing the inner circle of the front metal cover ring 7 from inside to outside, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com