Lifting device

A lifting device and lifting bracket technology, which is applied to furniture parts, household appliances, furniture accessories, etc., can solve problems such as unfavorable disassembly and maintenance, unstable positioning, and short service life, and achieve simplification of the overall structure and easy disassembly and assembly. With the effect of convenient maintenance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

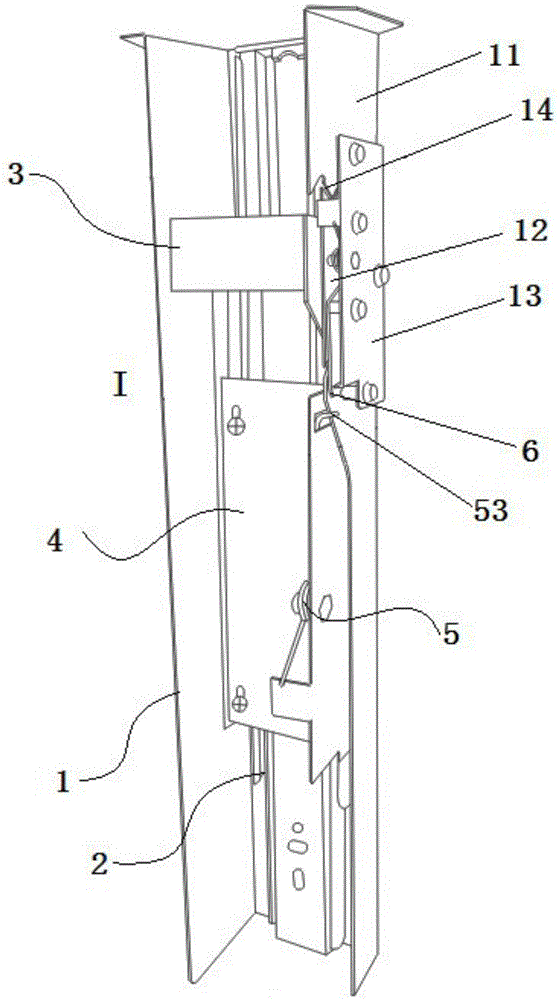

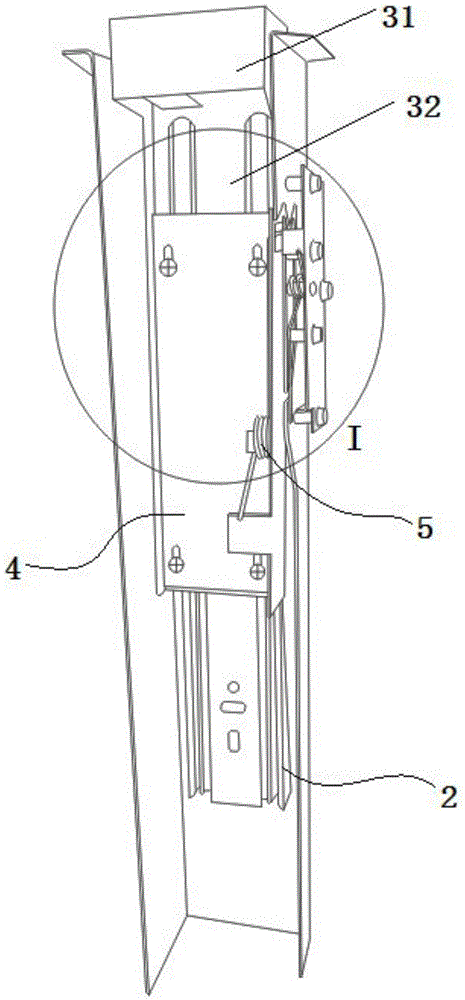

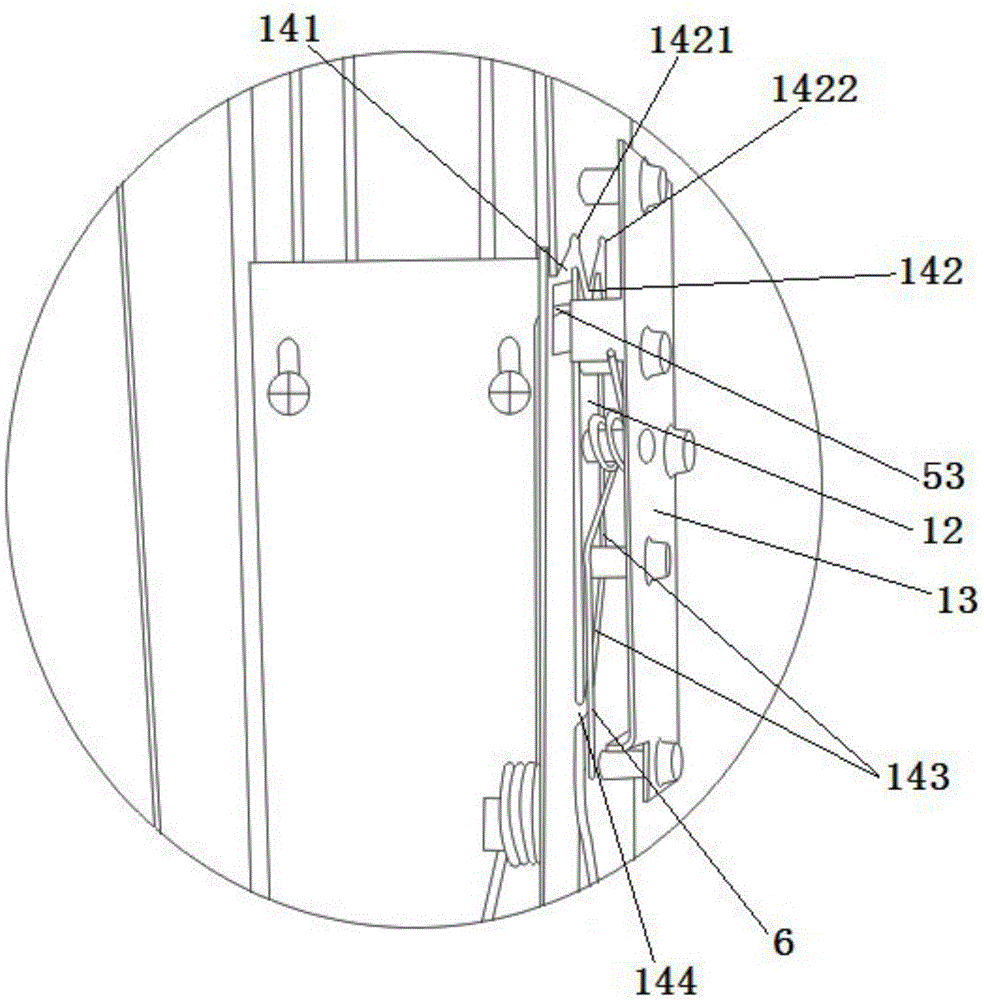

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated, and the direction of the present invention is based on figure 1 prevail.

[0026] combine Figure 1 to Figure 5 As shown, a lifting device includes a support base 1, a slide rail assembly 2, and a lifting bracket 3. The slide rail assembly 2 is fixed on the support base 1, and the lifting bracket 3 is arranged on the slide rail assembly 2 to move up and down with the slide rail assembly 2. slide.

[0027] The support seat 1 is a C-shaped channel steel, one side of which includes a side plate 11, a splicing plate 12 and a fixed plate 13, the side plate 11 has an inclined section 111, the transition from the bottom of the side plate 11 to the top through the inclined section 111, and the upper side of the side plate 11 is set There is a gap, the splicing plate 12 is combined with the side plate 11 in a non-contact manner through the gap, and the fixing plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com