Tool for manufacturing intersecting line opening of circular tube

A technology for manufacturing tooling and intersecting lines, which is applied to the field of manufacturing tooling for the opening of intersecting lines of circular pipes, can solve the problems of complicated calculation process, low hole-making efficiency, long manufacturing period, etc. The effect of simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

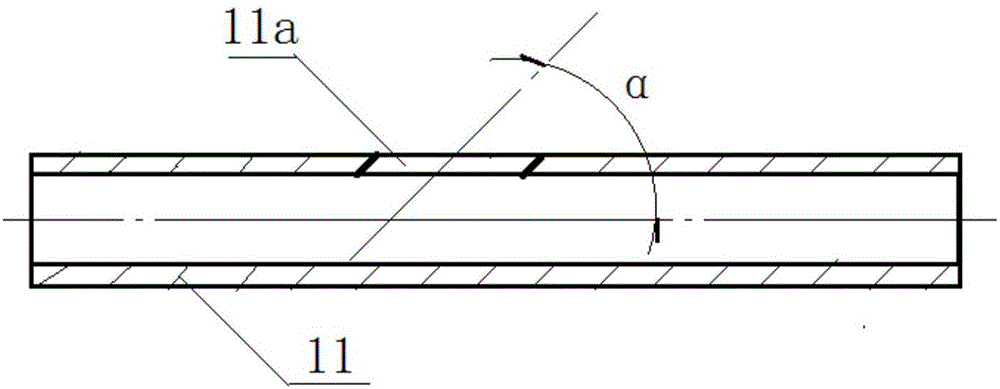

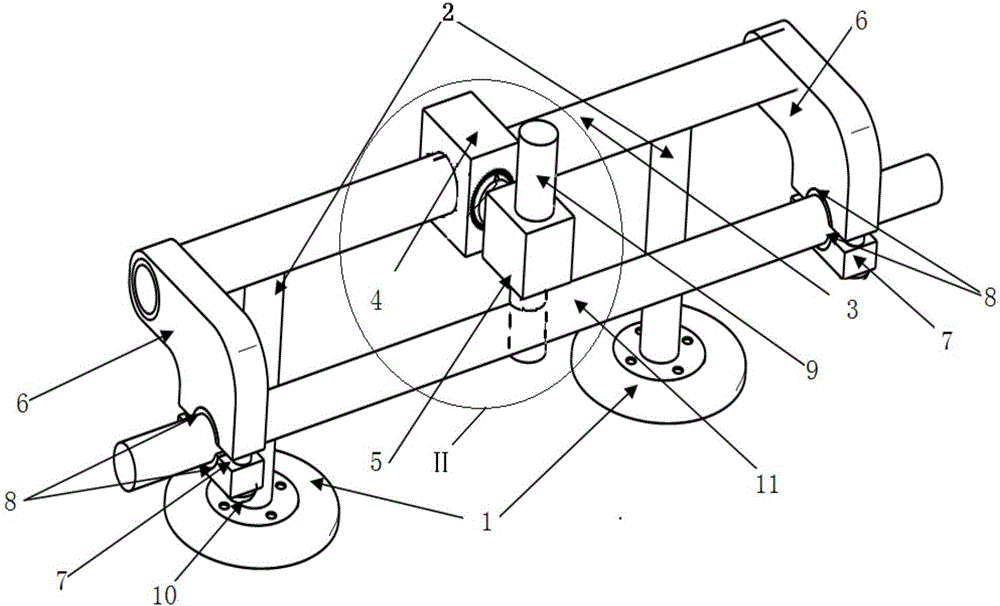

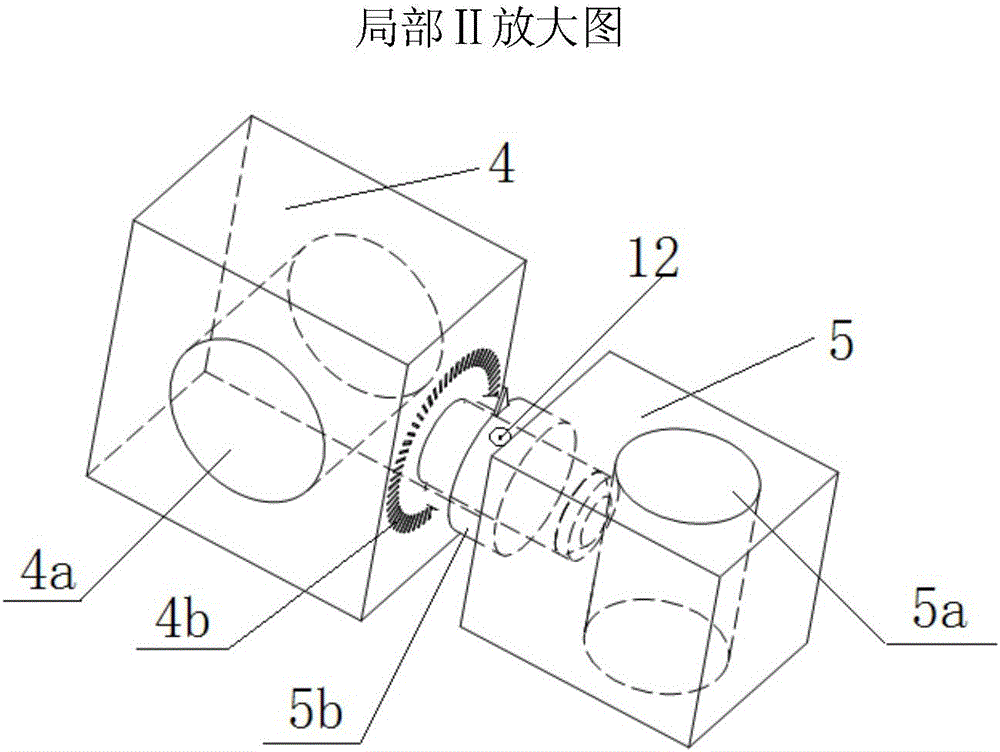

[0009] The present invention will be described in further detail below. see Figure 1 to Figure 3 , a round tube intersecting line opening manufacturing tooling needs to process an intersecting hole 11a on the processed round tube 11, and the included angle between the axis of the round tube 11 and the axis of the intersecting hole 11a is α=30°~150° , characterized in that: it includes a bracket assembly and a tool guide assembly; the bracket assembly consists of 2 bases 1 with vacuum suction cups, 2 columns 2, beams 3, indexing seats 4, 2 upper splints 6, and 2 lower splints 7. Composed of four semicircular bushings 8 and compression screws 10; the lower end of the column 2 is welded to the upper surface of the base 1 as a whole, the beam 3 is made of a circular or rectangular cross-section, and the upper end of the column 2 is connected to the beam 3 is welded as a whole, the indexing seat 4 is a cuboid, and there is a through hole 4a between the left surface and the right ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com