A centrifugal spiral spinning device

A technology of spinning device and spiral, which is applied in the field of centrifugal spiral spinning device, can solve problems such as complex centrifugal spinning structure, poor uniformity, poor sealing, etc., to achieve stability, simple equipment structure, and reduce viscosity changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

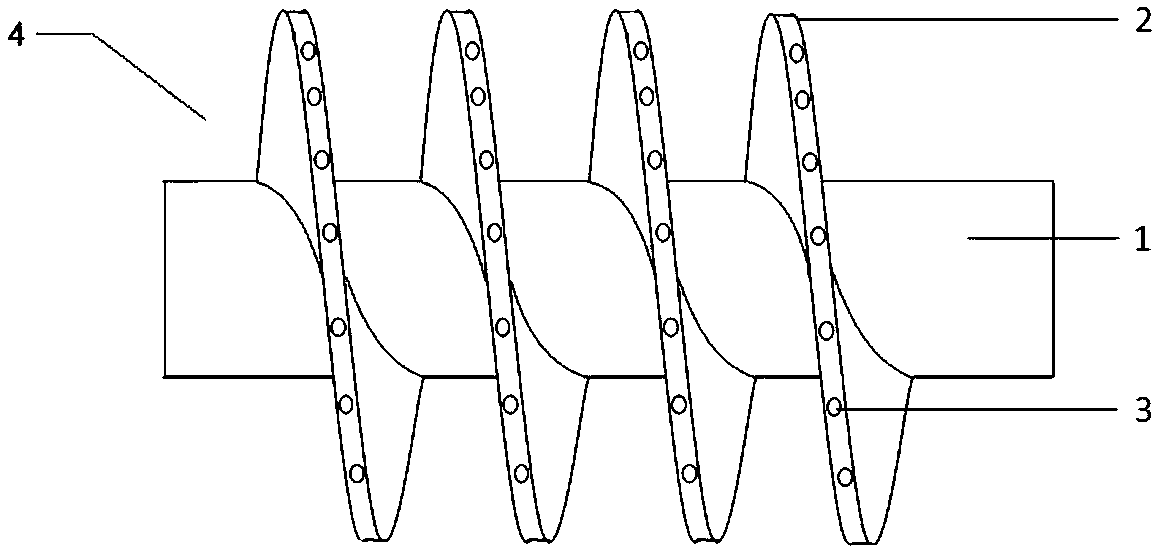

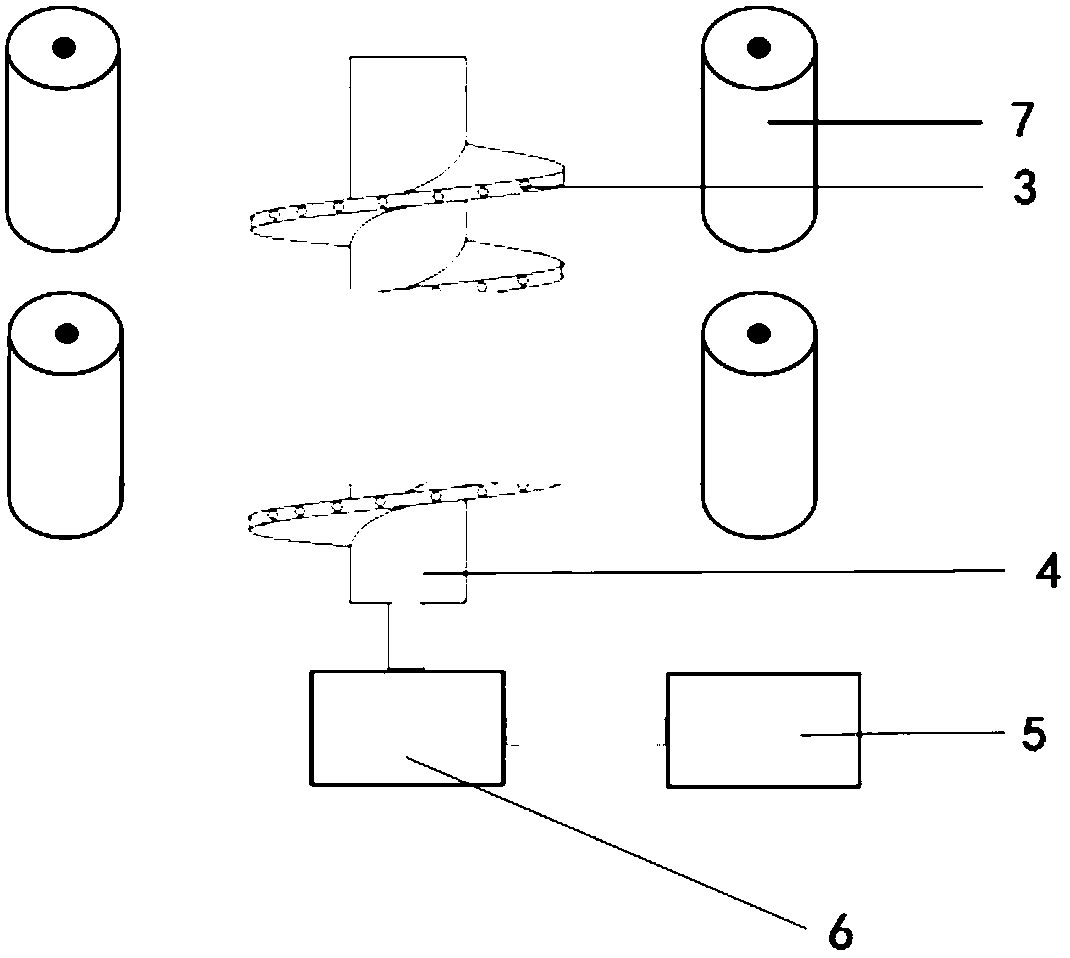

[0032] A centrifugal spiral spinning device, mainly used for processing polymer solution or melt into nanofibers. The centrifugal spiral spinning device comprises the above-mentioned centrifugal spiral spinning head 4, a power system 6, a feed liquid tank 5 and a continuous receiving device 7; Hole 3. The diameter of the hollow screw 1 of the centrifugal spiral spinning head 4 is 30mm, the diameter of the spiral blade 2 is 200mm, the pitch is 100mm, the diameter of the spinneret hole 3 is 0.2mm, and the total length of the centrifugal spiral spinning head 4 is 1200mm.

[0033] The continuous receiving device 7 is two groups of winders parallel to each other. The width of the winders is 1000mm, the distance from the centrifugal spiral spinning head 4 is 480mm, and the speed of the winders is 20m / min.

[0034] Polyvinyl alcohol PVA1799 is used for spinning, PVA1799 powder is added into hot water at 85° C., stirred and dissolved, and a spinning solution having a spinning solutio...

Embodiment 2

[0037] A centrifugal spiral spinning device, mainly used for processing polymer solution or melt into nanofibers. This centrifugal spiral spinning device comprises above-mentioned centrifugal spiral spinning head 4, power system 6, feed liquid tank 5, continuous receiving device 7 and applied electric field device (not shown in the figure); The screw blade 2 of centrifugal spiral spinning head 4 Spinning holes 3 are evenly distributed on the outer end surface perpendicular to the axial direction. The applied electric field device is located between the continuous receiving device 7 and the centrifugal spiral spinning head 4 .

[0038] The diameter of the hollow screw 1 of the centrifugal spiral spinning head 4 is 50 mm, the diameter of the spiral blade 2 is 200 mm, the pitch is 500 mm, the diameter of the spinneret hole 3 is 0.1 mm, and the total length of the centrifugal spiral spinning head 4 is 800 mm.

[0039] The continuous receiving device 7 is two groups of winders par...

Embodiment 3

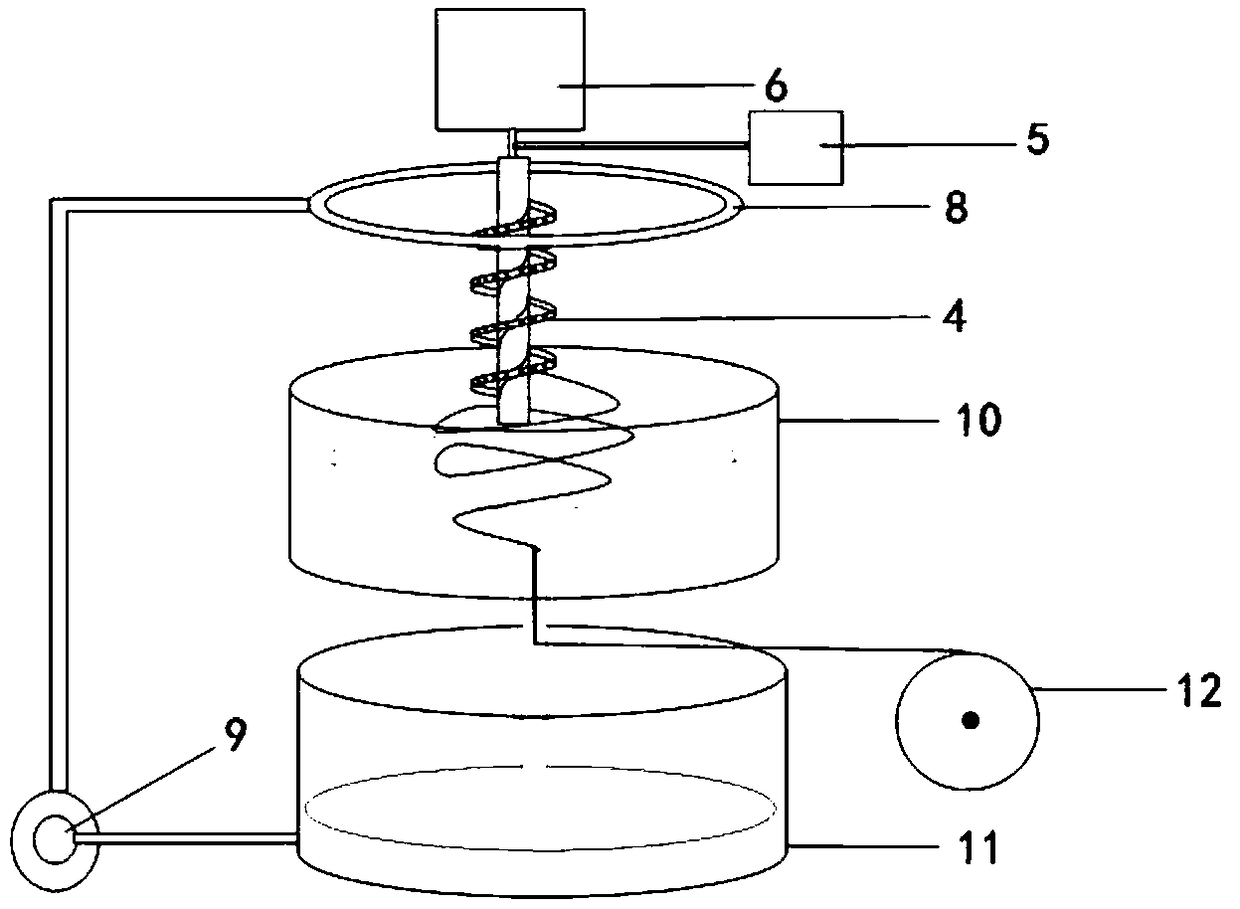

[0042] A centrifugal spiral spinning device, mainly used for processing polymer solution or melt into nanofibers. This centrifugal spiral spinning device comprises above-mentioned centrifugal spiral spinning head 4, power system 6, feed liquid tank 5, continuous receiving device 7 and induction heater (not shown in the figure); Spinning holes 3 are evenly distributed on the outer end surface perpendicular to the axial direction. The continuous receiving device 7 is a vortex solidification receiving device, including four parts: an annular water injection device 8, a vortex pool 10, a liquid collection pool 11, a circulating water pump 9 and a winding device 12. The circulating water pump 9 pumps the liquid from the liquid collection pool 11 into the The annular water injection device 8 forms a water curtain and surrounds the centrifugal spiral spinning head 4, and forms a vortex in the vortex pool 10, and the fibers form fiber bundles under the action of the vortex and are col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com