Product production system and method

A production system and product technology, applied in general control system, control/adjustment system, comprehensive factory control, etc., can solve problems affecting product production efficiency, production quality, abnormal important process parameters, manual operation of process parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiment of the present application provides a product production system and method, which are used to improve the production efficiency and production quality of the product.

[0036] The technical solutions provided in the embodiments of the present application can be applied to the production process of any product, for example, can be used to produce TFT-LCD.

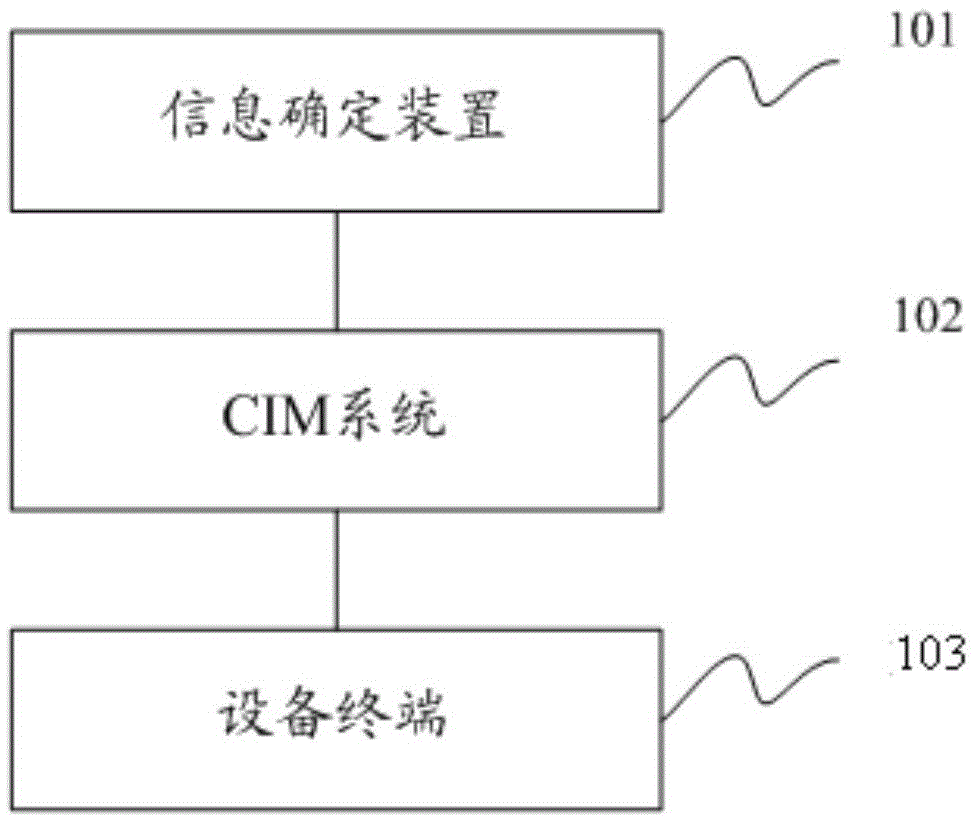

[0037] The technical solution provided by the embodiment of the present application can be used in the TFT-LCD binding process to realize the automatic generation of process parameters, see figure 1 , the system includes:

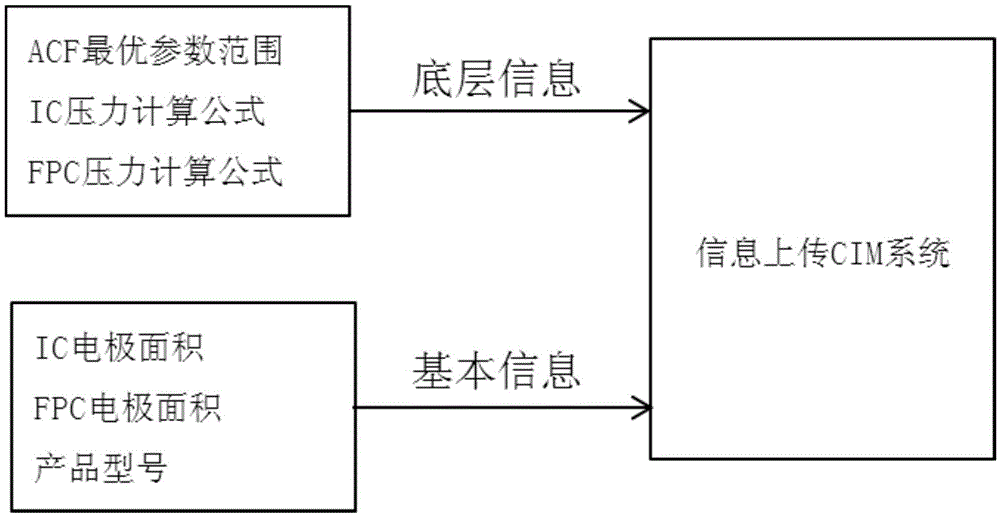

[0038] The information determination device 101 is used to determine the optimal parameter range of the anisotropic conductive adhesive (ACF); and send the underlying information including the optimal parameter range of the ACF and the basic information to the production intelligent collection CIM system;

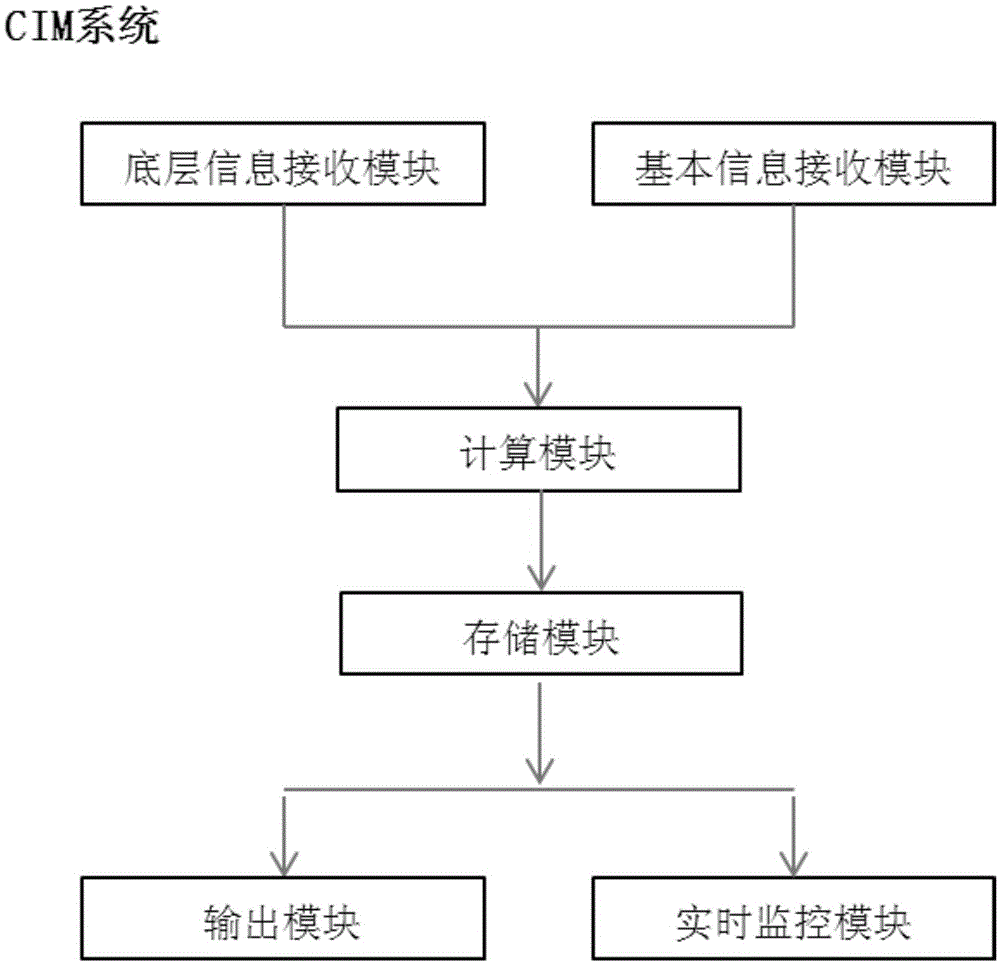

[0039] The CIM system 102 is configured to receive the underlying informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com