A method for surface modification of hot work die steel materials based on cim process

A technology for surface modification of hot work die steel, applied in the field of surface modification of hot work die steel materials, can solve the problems of high cost, short service life, low bonding strength, etc., achieve low production cost, improve service life, and solve service life low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

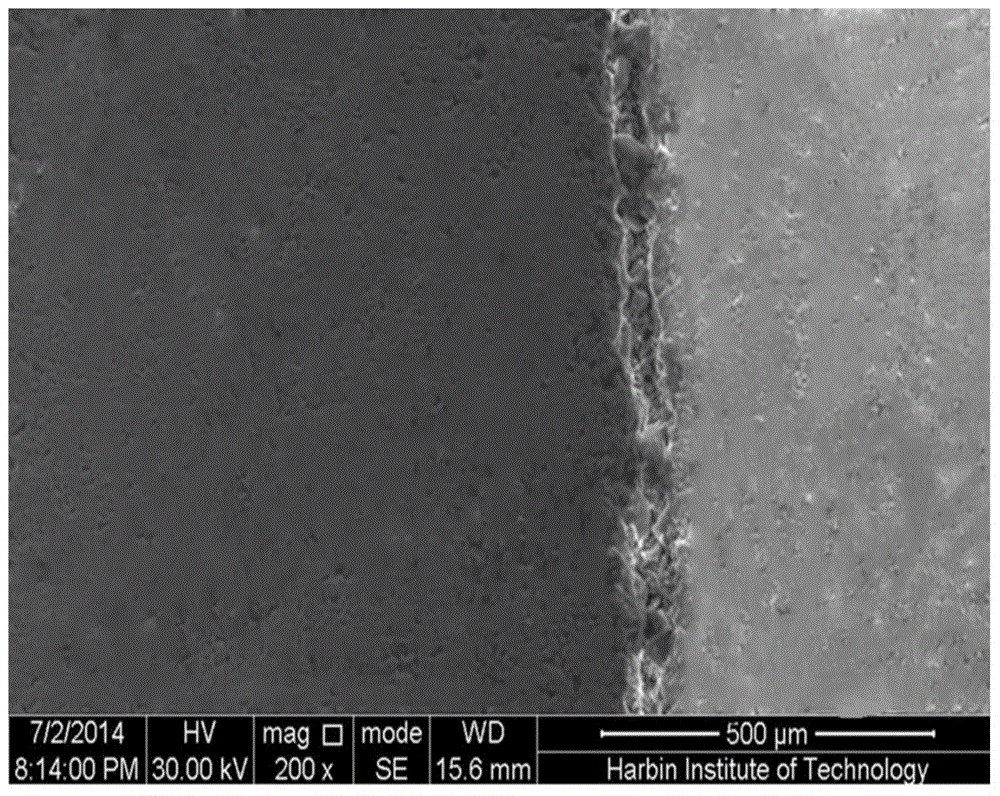

Image

Examples

specific Embodiment approach 1

[0032] Embodiment 1: This embodiment is a method for surface modification of hot work die steel materials based on CIM technology, which is specifically completed according to the following steps:

[0033] 1. For Y 2 o 3 Stabilized zirconia powders were modified: the Y 2 o 3 The stable zirconia powder is sintered at a temperature of 900°C to 1100°C for 1h to 2h, and then cooled to room temperature with the furnace, and then to Y 2 o 3 Add modifiers and grinding aids to the stable zirconia powder, then use zirconia ceramic balls to perform wet ball milling for 20h-24h, then dry at a temperature of 40°C-60°C for 8h-10h, and then sieve to obtain Modified Y with a particle size of 0.8 μm to 1.0 μm 2 o 3 Stabilized zirconia powder;

[0034] The zirconia ceramic ball and Y described in step one 2 o 3 The mass ratio of stable zirconia powder is 4:1;

[0035] Y as described in Step 1 2 o 3 The mass ratio of stable zirconia powder to grinding aid is 1:1;

[0036] Y as desc...

specific Embodiment approach 2

[0055] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the hot work die steel material in step 3 is 5CrNiMo, 5CrNiTi, 5CrMnMoSiV, 4CrW2Si, 4Cr5MoSiV1 or 3Cr2W8V. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0056] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the modifying agent described in step 1 is stearic acid. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com