Printed wiring board and method of producing the same

A printed circuit board, one-sided technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the problems that hinder the miniaturization of the unit unit, and achieve the effect of reducing high-frequency noise current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

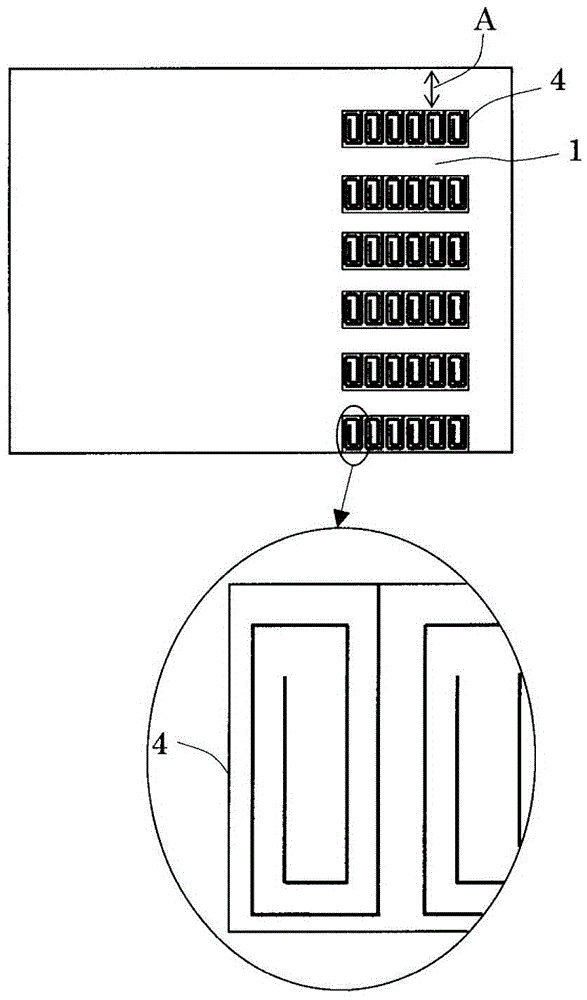

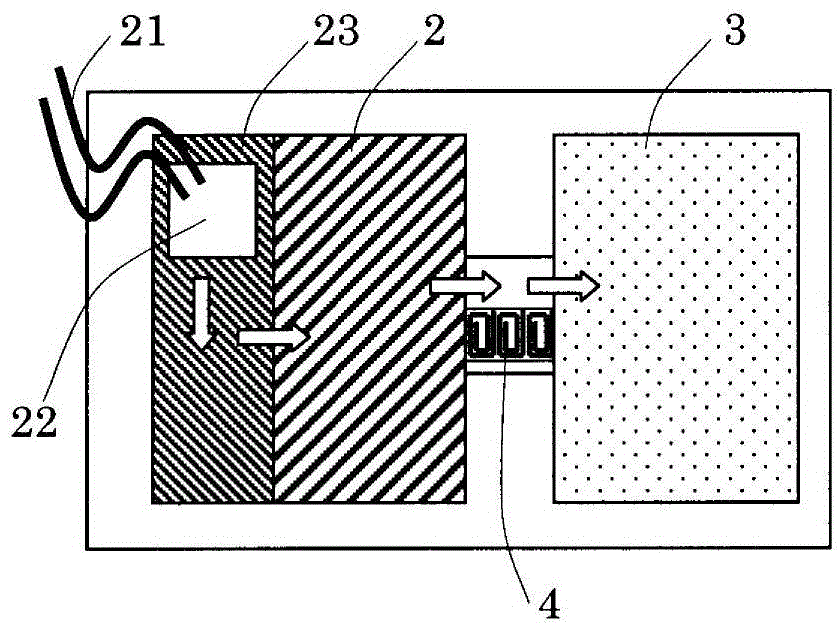

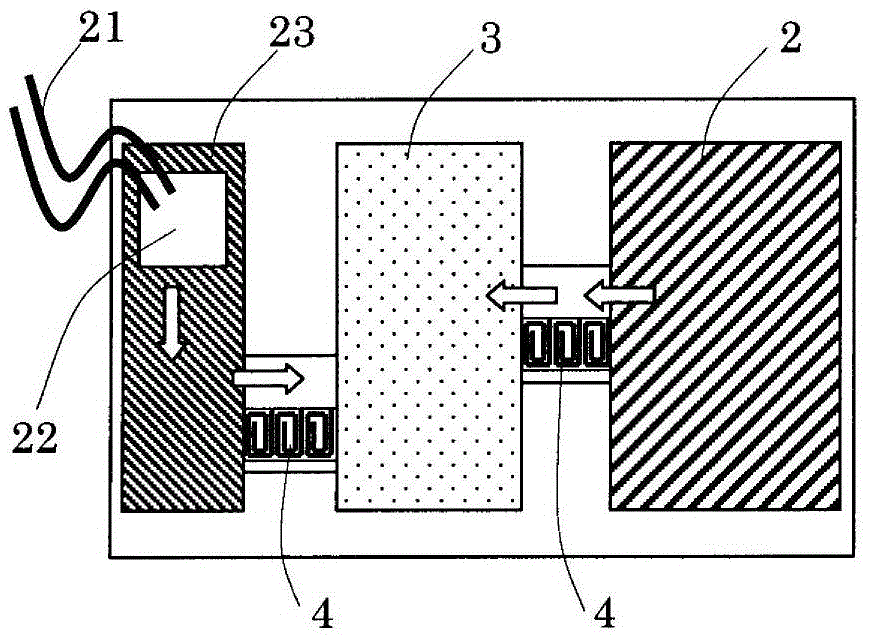

[0025] The printed wiring board according to one embodiment of the present invention will be described based on the drawings. In printed circuit boards, such as figure 1 As shown, the power layer width (width A) of the part connecting the digital power module and the analog power module is a width that satisfies the current value required by the IC (semiconductor integrated circuit), which can be 2-6mm, preferably 3-4mm . There may be one bridge 1 or multiple bridges.

[0026] The shape of the open stub EBG structure 4 formed on the power supply pattern (power supply path) of the printed circuit board, such as figure 1 As shown in the partial enlarged view, it is better to form a vortex with the open part as the center and minimize the occupied area as much as possible. The spiral shape can be bent regardless of whether it is a curve or a straight line, and the position and number of bending are arbitrary in the case of bending. The bending angle is also not limited to a righ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com