Chive oil essence

A technology of shallot oil and shallot, which is applied in the field of shallot oil essence and its preparation, can solve the problems of large aroma loss, large dosage, low cost performance, etc., and achieve strong aroma, good stability, smooth and natural aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

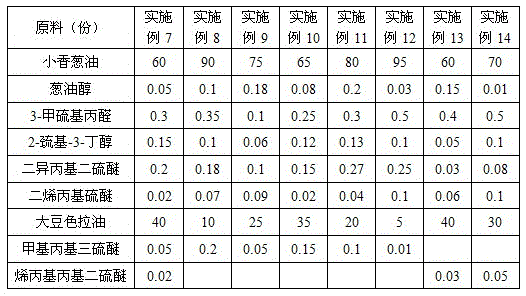

Examples

Embodiment 1

[0013] A shallot oil essence, mainly prepared from the following raw materials in parts by weight: 60-95 parts of shallot oil, 0.01-0.2 parts of shallot alcohol with a concentration of 10%, 0.1-0.5 parts of 3-methylthiopropanal 0.05-0.15 parts of 2-mercapto-3-butanol, 0.03-0.3 parts of diisopropyl disulfide, 0.02-0.1 parts of diallyl sulfide, 5-40 parts of first-grade soybean salad oil; Scallion oil is prepared by the following steps: Wash shallots and cut them into 1-5cm pieces, add soybean salad oil and shallots into the reaction kettle at a weight ratio of 1:1-3:1, and heat up to 40 -80°C, soak for 16-36h, filter the scallions, get shallot oil-water mixture, stand and separate to get shallot oil; 10% scallion oil as solvent is soybean salad oil, 10% scallion Oleyl alcohol; the remaining raw materials are natural or synthetic products equivalent to natural.

[0014] Scallion oil has rich onion fragrance, high temperature resistance and long-lasting aroma; 3-methylthiopropio...

Embodiment 2

[0016] Wash the fresh shallots and cut them into small pieces of about 2cm for later use. Add an appropriate amount of soybean salad oil into the reaction kettle, add the shallots in a ratio of 1:1 by weight, raise the temperature to 60°C, soak for 24 hours, and filter the shallots. Segment, to obtain shallot oil-water mixture, stand to separate, obtain shallot oil; then take shallot oil 90g, concentration 10% shallot alcohol 0.1g, 3-methylthiopropanal 0.2g, 2-mercapto -3-butanol 0.1g, diisopropyl disulfide 0.2g, diallyl sulfide 0.05g, methyl propyl trisulfide 0.08g, allyl propyl disulfide 0.03g, primary 9.24 g of soybean salad oil; the rest are the same as in Example 1; the shallot oil essence prepared by the above-mentioned method has a vivid, strong flavor and good stability, and is applicable to various snack food seasonings.

Embodiment 3

[0018] Wash the fresh shallots and cut them into small pieces of about 3cm for later use. Add an appropriate amount of soybean salad oil into the reaction kettle, add the shallots in a ratio of 2:1 by weight, raise the temperature to 70°C, soak for 30 hours, and filter the shallots. Segment, to obtain shallot oil-water mixture, stand to separate, obtain shallot oil; then take shallot oil 92g, concentration 10% shallot alcohol 0.15g, 3-methylthiopropanal 0.3g, 2-mercapto -3-butanol 0.08g, diisopropyl disulfide 0.1g, diallyl sulfide 0.06g, methyl propyl trisulfide 0.1g, allyl propyl disulfide 0.02g, primary 7.19g of soybean salad oil; the rest are the same as in Example 1; the shallot oil essence prepared according to the above method and formula has stable flavor and strong and attractive onion flavor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com