Side guide roller

A technology of side guide roller and roller body is applied in the field of hot-rolled strip steel production equipment, which can solve the problems of high temperature and high speed, and achieve the effect of avoiding cost and benefit problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

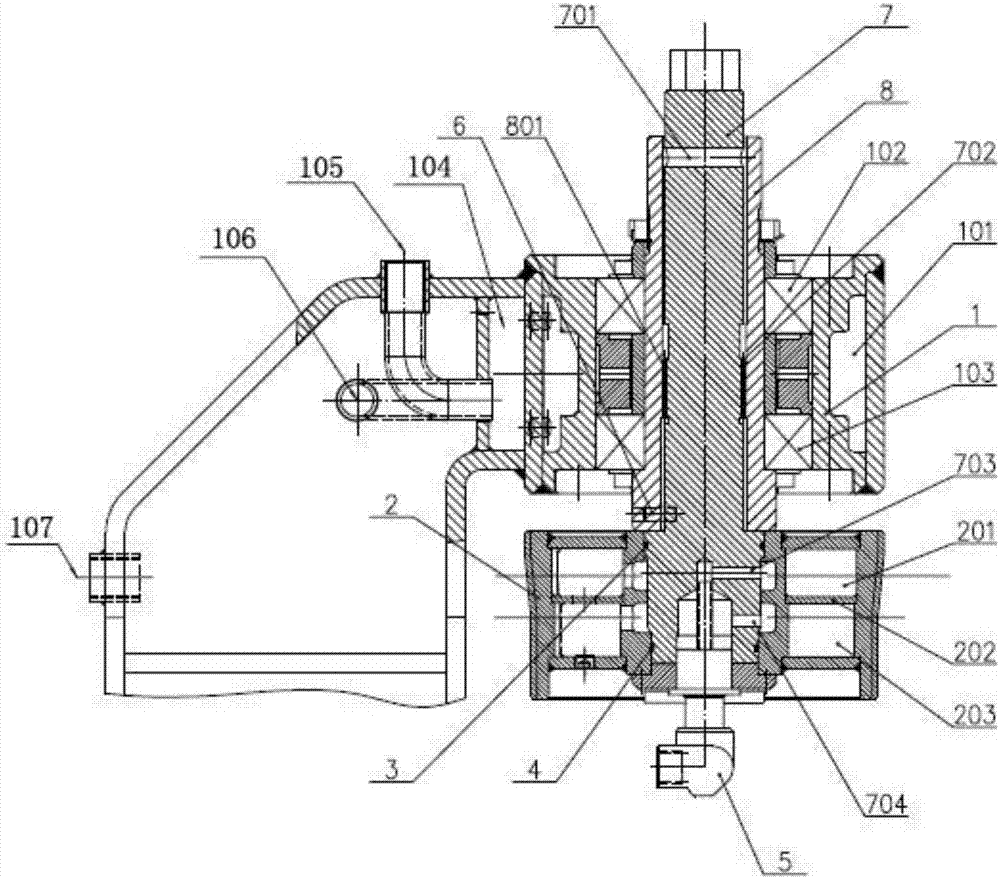

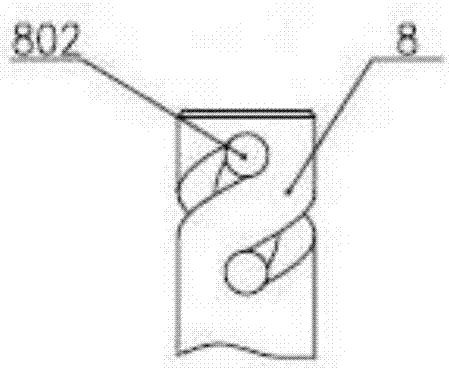

[0018] like figure 1 As shown, the side guide roller of the present invention mainly includes a roller housing 1 , a roller body 2 , a fixed pin 6 , a moving shaft 7 and a fixed shaft 8 .

[0019] A first bearing 102 and a second bearing 103 are installed inside the roller base 1 . Wherein, the first bearing 102 adopts an impact-resistant cylindrical roller bearing, which can withstand a large radial impact force brought by the slab; the second bearing 103 adopts a self-aligning roller bearing to bear axial force. The inner ring of the bearing is sleeved on the fixed shaft 8, and the fixed shaft 8 can only rotate, and its fixing method adopts lock nuts etc. to fix on the top of the roller seat 1.

[0020] The fixed sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com