A kind of container hoisting method

A hoisting method and container technology, which is applied in the hoisting of containers at the wharf and in the field of container hoisting, can solve the problems of reducing operating efficiency, achieve the effects of increasing utilization rate, increasing loading and unloading while reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Container hoisting method of the present invention, as figure 1 As shown, it includes a process of operating a double-forty-foot double-lift bridge crane, wherein, in the process of operating a double-forty-foot double-lift bridge crane, the double forty-foot double-lift bridge is used The crane lifts a first container and a second container respectively from two trucks at the same time, and then uses double 40-foot double-lift bridge cranes to load the above-mentioned first container and the second container onto a ship at the same time, and then from A third container and a fourth container are hoisted on the ship at the same time, and finally the third container and the fourth container are respectively loaded onto the two collection trucks by using double forty-foot double-lift bridge cranes superior.

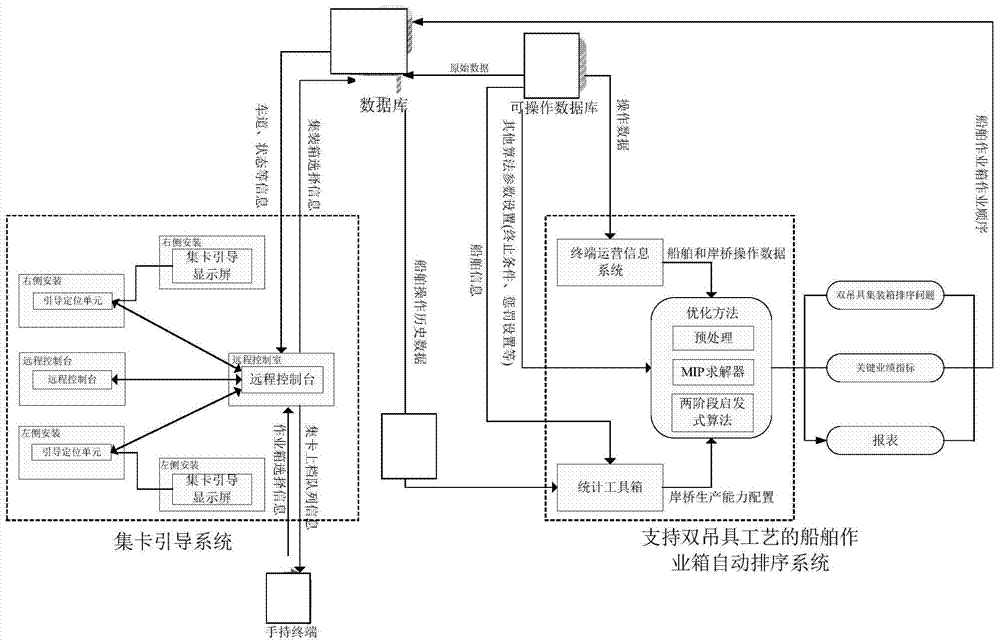

[0051]Further, use a collection truck guidance system and a ship operation box process and sorting system to guide the action of the collection truck and the action...

Embodiment 2

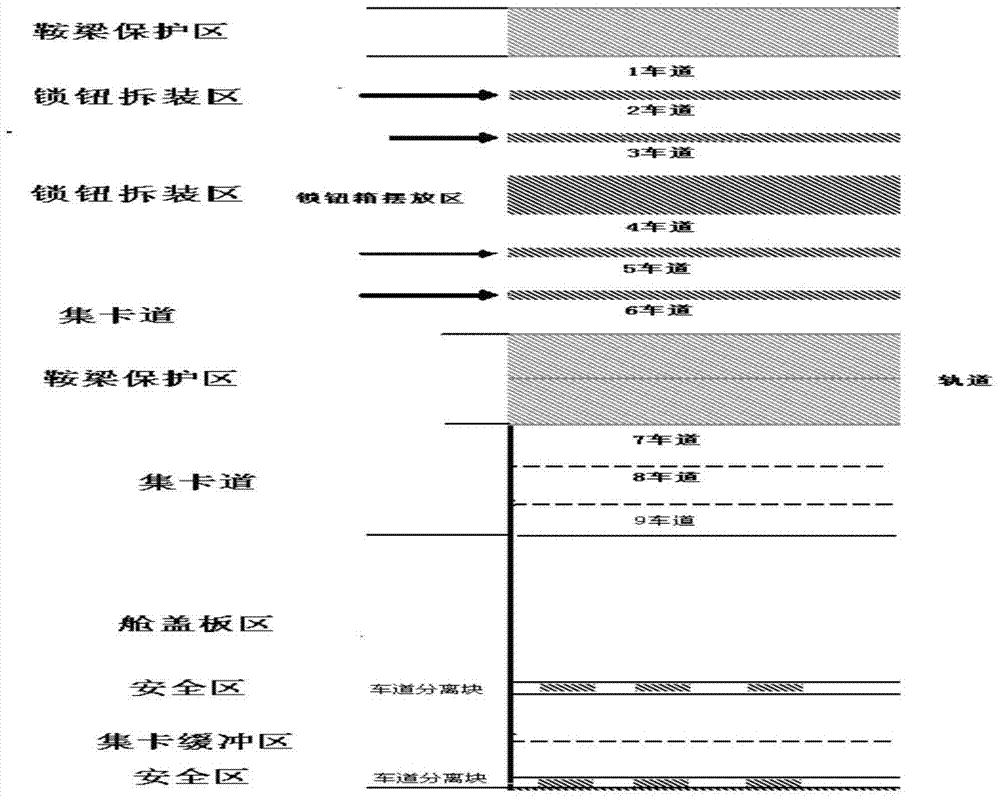

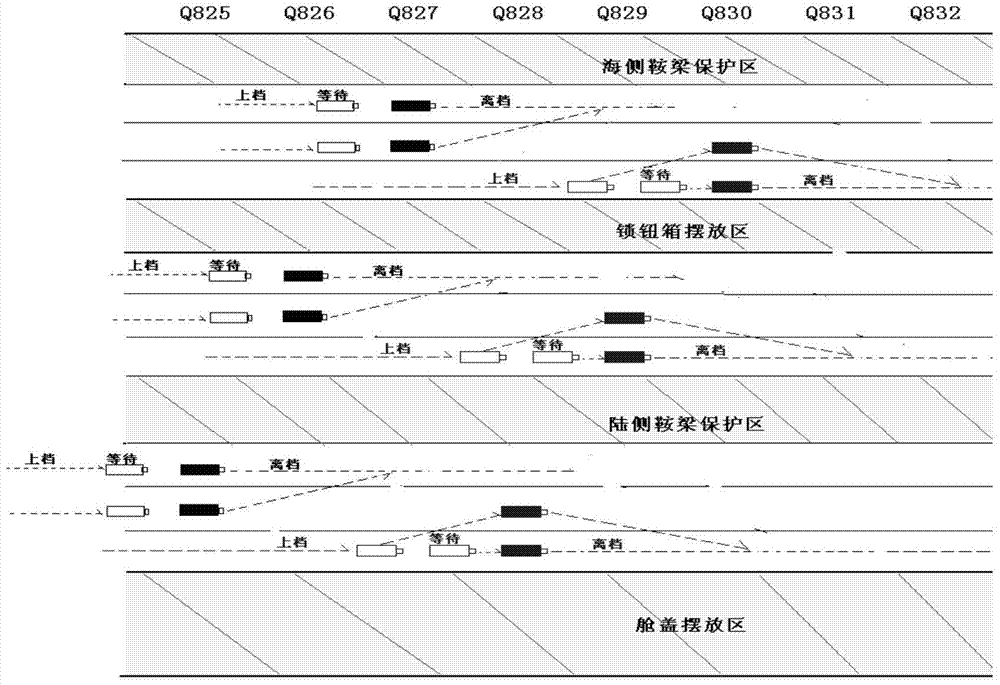

[0056] Such as image 3 As shown in the figure, it realizes the loading and unloading of the collection card. For the truck loading and unloading of the truck guidance system, after the work lanes are divided, the production organization model of the double-lifting bridge crane operation truck loading and unloading production organization model has been developed according to the re-established work lane specifications. Considering that in order to make full use of the terminal The platform is not rich in lane resources, ensuring that multiple double-lift bridge cranes can operate a ship at the same time. On the premise of avoiding the opening and closing of the circuit, the breakthrough of two double-lift cranes that meet the safety of the collection truck The working lanes of the hoisting bridge cranes are arranged on 3 lanes, so that one of the lanes of the two bridge cranes can be used as a shared lane for cross use. The shifting lanes and shifting sequence of the work tr...

Embodiment 3

[0058] The wharf truck collection guidance system of the present invention can cooperate with drivers and operators of wharf equipment such as quayside cranes to realize efficient and fast operations. Such as Figure 5 As shown, the system includes a remote console, a lane monitoring unit, a guidance and positioning unit, and a collection truck guidance display. The remote console is used to set the operation parameters of the collection truck. These parameters include, for example, the working lane, the direction of the collection truck, the type of the collection truck, the type of the operation box, etc., and are used to monitor the guidance process of the collection truck. In one embodiment, the remote console can be an embedded human-computer interaction platform based on WinCE operating system. In terms of functions, the remote console provides basic serial port and network functions, data communication with programmable logic controllers, hardware control and data feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com