Anchor construction method

A construction method and bolt technology, which are applied in the directions of bolt installation, earthwork drilling, infrastructure engineering, etc., can solve the problems of insufficient bearing capacity and low end bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

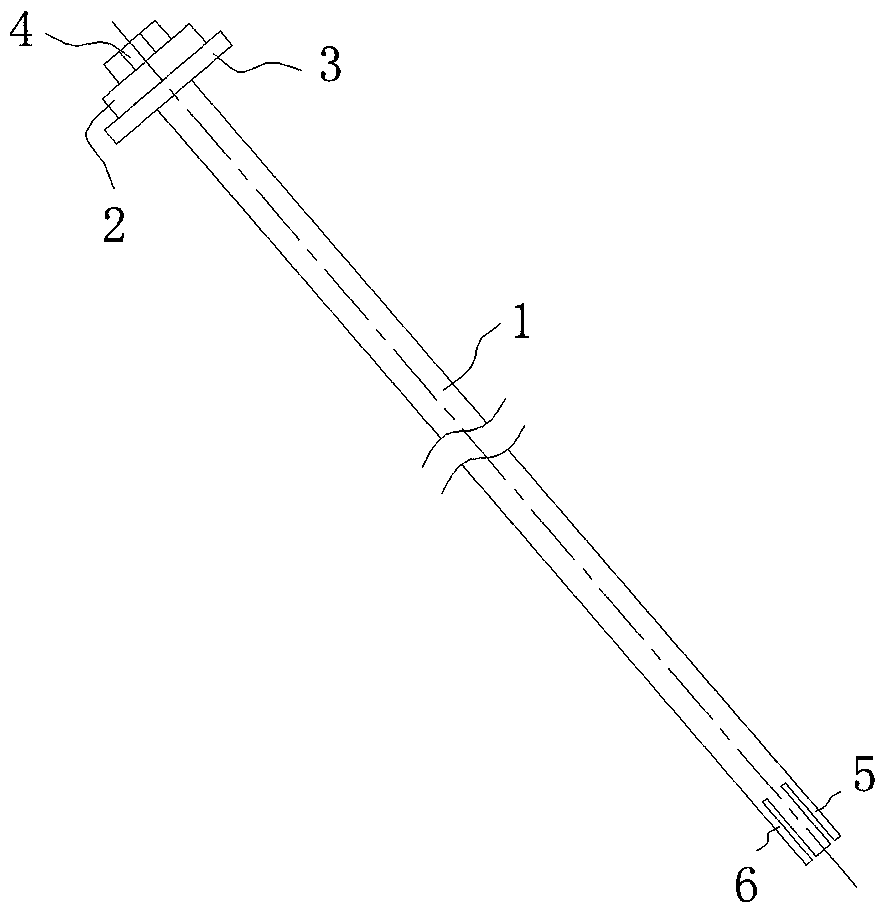

[0036] like figure 1 As shown, a kind of anchor rod includes a hollow tubular anchor rod body 1 with upper and lower openings. The bottom of the anchor rod body 1 is uniformly provided with four axial opening grooves 5, and the opening grooves 5 connect the anchor rod body 1. The bottom is divided into four anchoring support pieces 6, wherein the opening height of the opening groove 5 on the anchor rod body 1 is preferably 0.1 to 0.2 times the length of the anchor rod body 1, and the top of the anchor rod body 1 is provided with a baffle plate connected thereto 2. The baffle 2 is fixed by nuts 4, and a backing plate 3 is provided between the baffle 2 and the anchor rod body 1, and the backing plate 3 is sleeved on the top of the anchor rod body 1.

[0037] In order to improve the anchoring effect, threads (not shown in the figure) can be provided on the outer surface of the anchor rod body 1, so as to enhance the friction force on the outer surface of the anchor rod body 1 . ...

Embodiment 2

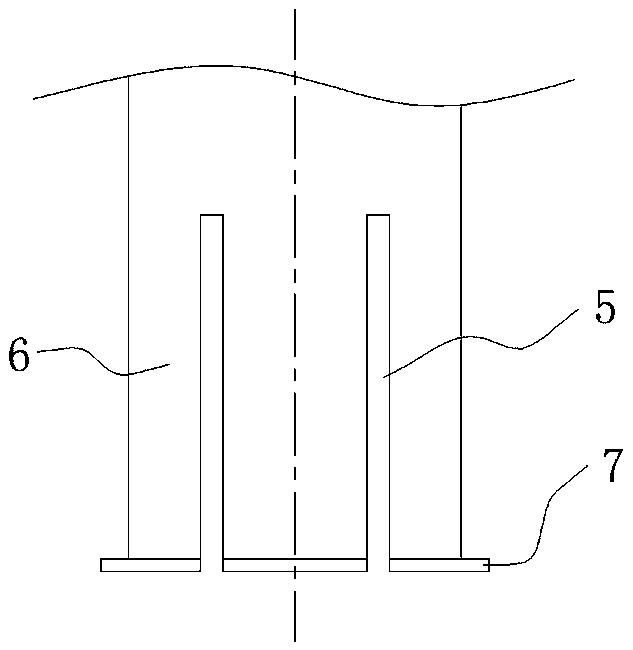

[0039] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the lower end of the anchoring support piece 6 is provided with a flange 7 extending outward. The arrangement of the flange 7 makes it possible for the anchor support piece 6 to be stuck in the cavity 9 by virtue of the flange 7 even if it is not fully expanded.

Embodiment 3

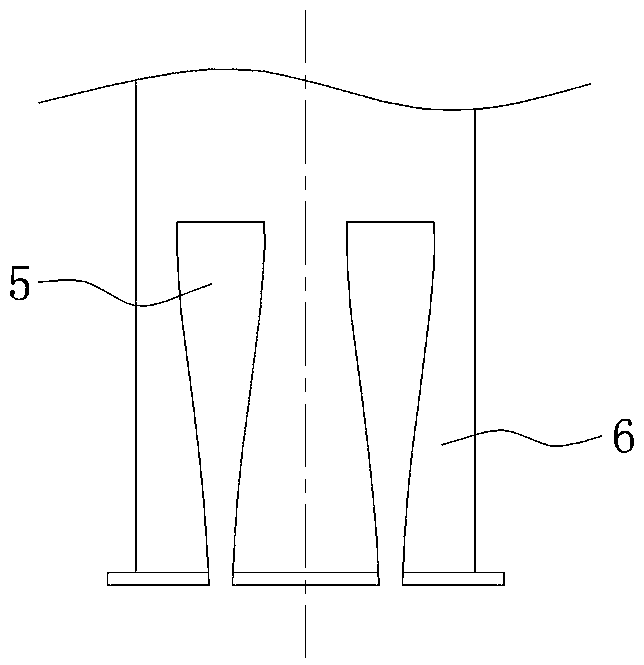

[0041] like image 3 As shown, this embodiment has made further improvements to Embodiment 2, and it sets the opening groove 5 to a shape whose upper end opening is larger than the lower end opening, so that the upper end of the anchor support piece 6 is narrower, and under the same pressure, it is easier to For external expansion, preferably, the size of the upper opening of the open groove 5 is 2-3 times that of the lower opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com