Tensile hose and assembly for enhancing strength of hose

A hose and tensile-resistant technology, applied in the field of hoses, can solve problems such as undiscovered hose structure, and achieve the effect of improving tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in the form of embodiments below in conjunction with the accompanying drawings, so as to assist those skilled in the art to understand and realize the present invention. Unless otherwise stated, the following embodiments and technical terms therein should not be understood without departing from the background of technical knowledge in this technical field.

[0039] The first part of the invention:

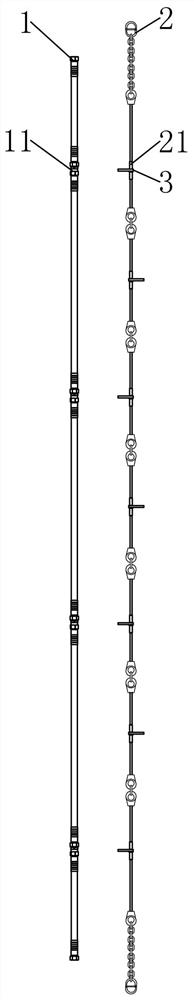

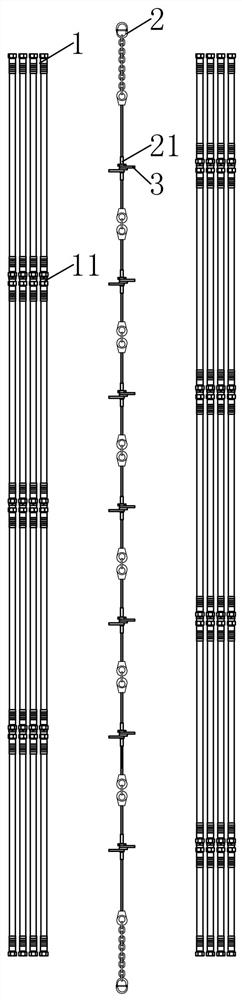

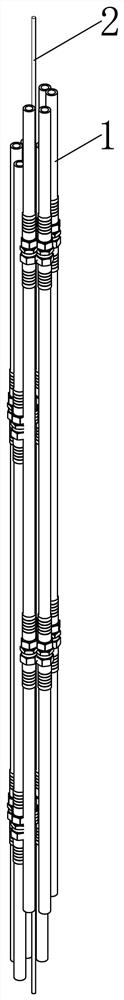

[0040] A tensile hose, see figure 1 , including a hose main body 1, a bearing cable 2 and a node connector 3, the hose main body 1 is provided with a hose lifting application node 11, and the bearing cable 2 is provided with a cable application node 21, and the node The connecting piece 3 is used to connect the hose lifting force application node 11 and the cable force application node 21 .

[0041] Generally, a plurality of hose lifting force application nodes 11 are arranged in the pipeline direction of the hose main body 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com