Novel computer anti-snapping transmission line automatic braiding mechanism

A computer and anti-pull technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of data line damage, low data line resistance to pull, and reduced service life of data lines, so as to achieve enhanced tensile capacity, The winding wire is compact and enhances the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

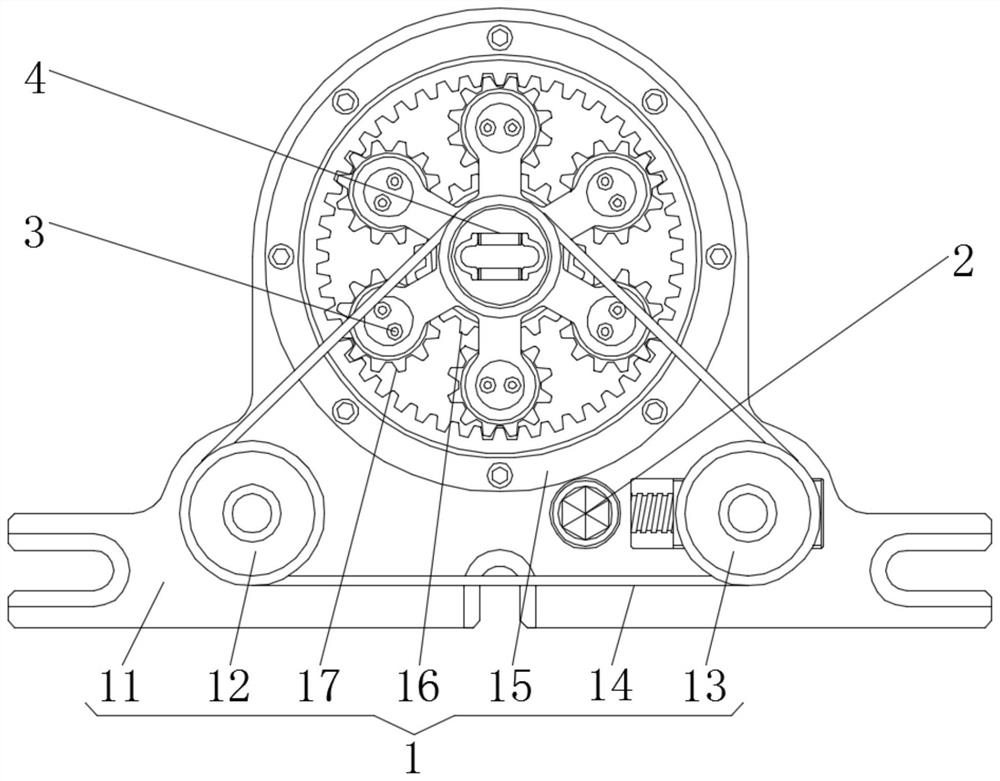

[0022] see Figure 1-2 , a new type of computer automatic weaving mechanism for anti-breaking transmission lines, including a weaving mechanism 1, the weaving mechanism 1 includes a frame 11, the front of the frame 11 is connected with a drive wheel 12 and an adjustment wheel 13 for rotation, and the outer drive wheel 12 is connected with a drive wheel. Synchronous belt 14, the inside of frame 11 is fixedly connected with fixed gear 15, and the positive rotation of fixed gear 15 is connected with the turret that adapts to sun gear 16 and planetary gear 17, and the inside of frame 11 is provided with and fixed gear 15 fits. A circular through hole is arranged, and the inside of the frame 11 is provided with a rectangular groove adapted to the adjusting frame 21. The inside of the fixed gear 15 is meshed with a planetary wheel 17, and the planetary wheel 17 is meshed with a sun wheel 16.

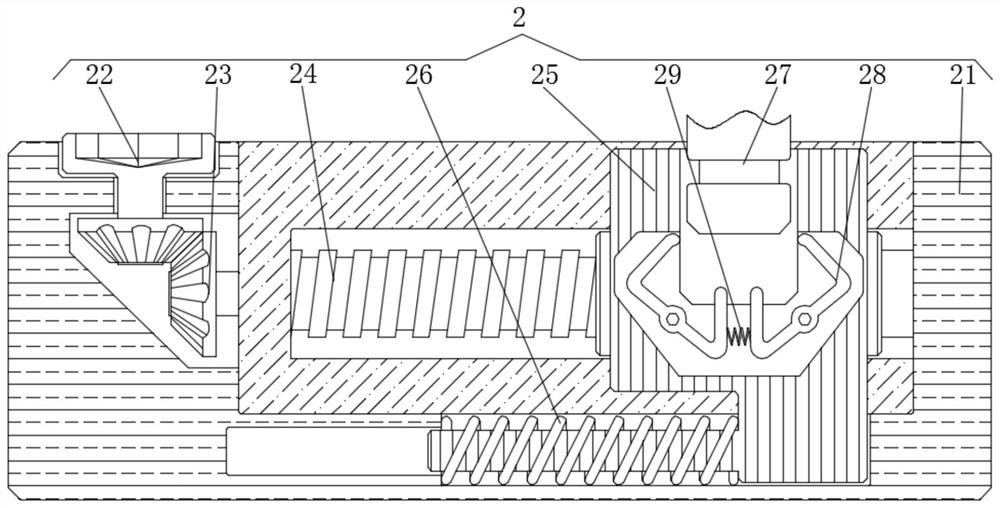

[0023] It also includes an adjustment mechanism 2, the adjustment mechanism 2 includes an ...

Embodiment 2

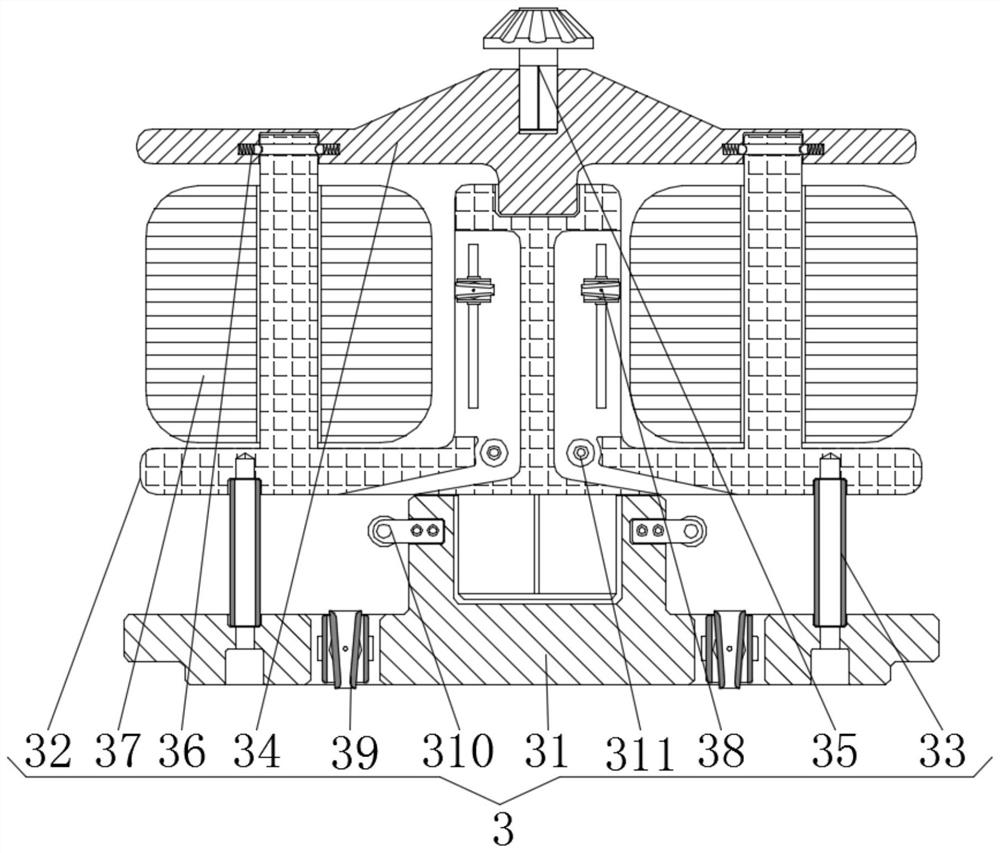

[0025] see figure 1 with Figure 3-4 , a new type of automatic computer braiding mechanism for anti-breakage transmission lines, also includes a wire winding mechanism 3, the wire winding mechanism 3 includes a wire winding seat 31, and the inside of the silk winding seat 31 is provided with a circular groove that is adapted to the swing wire harness 39 , the top of the wire winding seat 31 is provided with a square groove adapted to the wire storage rack 32, and the inside of the silk winding seat 31 is provided with a circular countersink hole adapted to the supporting guide post 33, and the transmission gear 35 meshes with the meshing gear 42 connection, the top of the wire winding seat 31 is clamped with a wire storage rack 32, the top of the silk winding base 31 is fixedly connected with a support guide post 33, the top of the wire storage rack 32 is clamped with a cover plate 34, and the top of the cover plate 34 The drive gear 35 is fixedly connected, the inside of the...

Embodiment 3

[0028] see Figure 1-4 , a new type of computer automatic weaving mechanism for anti-breaking transmission lines, including a weaving mechanism 1, the weaving mechanism 1 includes a frame 11, the front of the frame 11 is connected with a drive wheel 12 and an adjustment wheel 13 for rotation, and the outer drive wheel 12 is connected with a drive wheel. Synchronous belt 14, the inside of frame 11 is fixedly connected with fixed gear 15, and the positive rotation of fixed gear 15 is connected with the turret that adapts to sun gear 16 and planetary gear 17, and the inside of frame 11 is provided with and fixed gear 15 fits. A circular through hole is arranged, and the inside of the frame 11 is provided with a rectangular groove adapted to the adjusting frame 21. The inside of the fixed gear 15 is meshed with a planetary wheel 17, and the planetary wheel 17 is meshed with a sun wheel 16.

[0029] It also includes an adjustment mechanism 2, the adjustment mechanism 2 includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com