Flexible far-infrared heating film, preparation method thereof and far-infrared blanket produced through same

A far-infrared heating film and far-infrared heating technology are applied in the field of far-infrared blankets, which can solve the problems of inability to cut at will, lack of health care, and fixed size, so as to eliminate static electricity and sparks, and facilitate folding and storage. Effect of transportation, improvement of flexibility and tensile resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

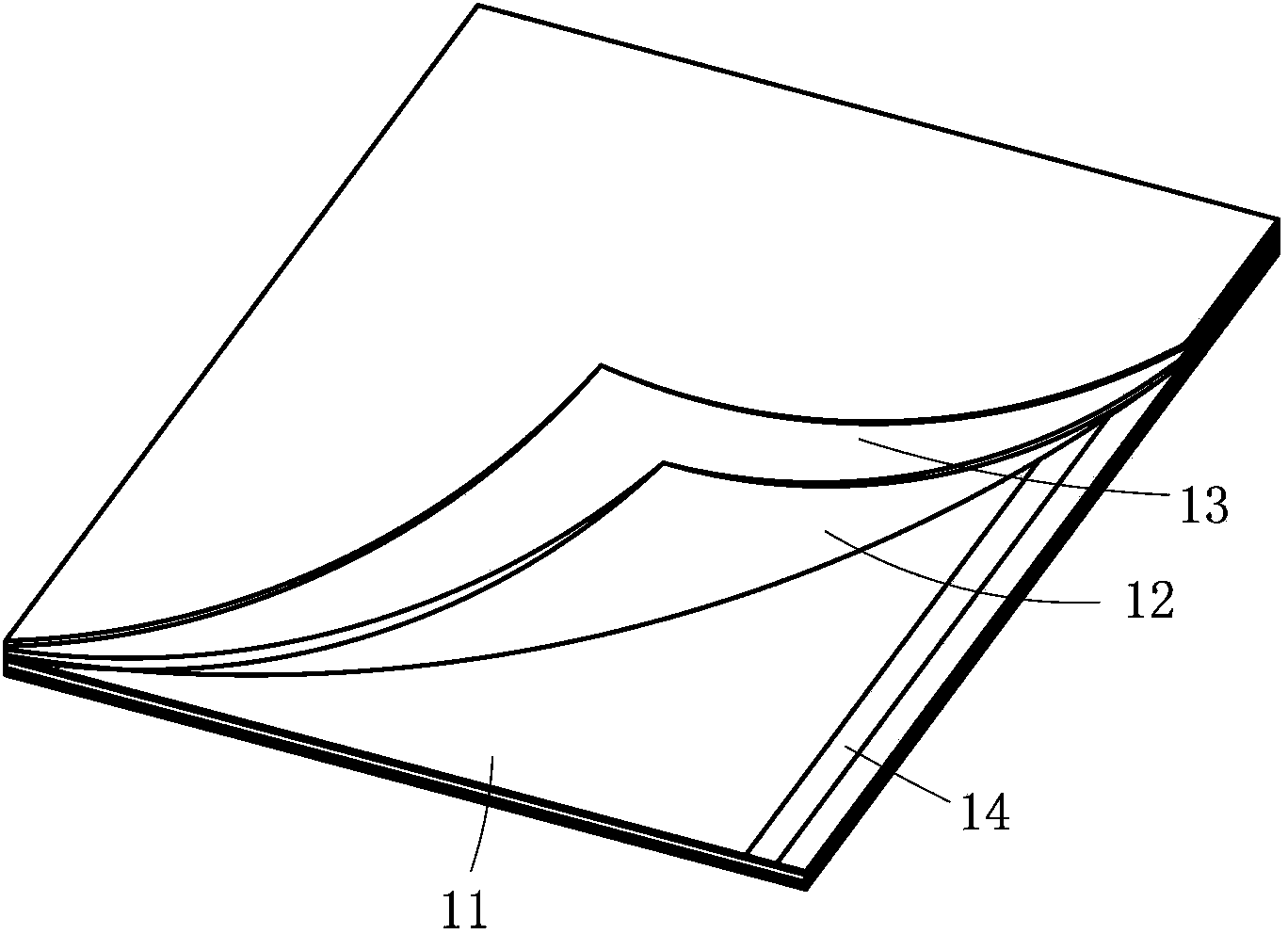

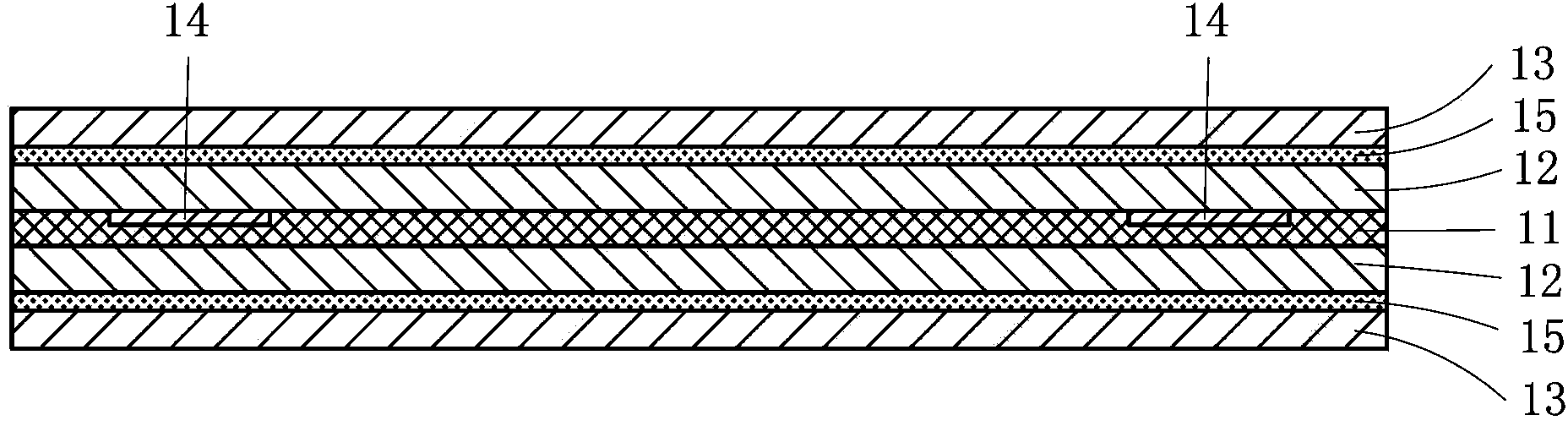

[0033] Such as figure 1 with figure 2 As shown together, a flexible far-infrared heating film includes a far-infrared heating layer 11, electrodes 14 are implanted on both sides of the far-infrared heating layer 11, and the extension direction of the electrodes 14 is consistent with the extension direction of the far-infrared heating layer 11. A flexible insulating layer 12 is attached to the front and back surfaces of the far-infrared heating layer 11, and a metal shielding layer 13 is attached to the outside of the two-layer flexible insulating layer 12; the far-infrared heating layer 11 is formed by mixing conductive ink and far-infrared emitting agent. The far-infrared emitting agent is carbon crystal, wherein the conductive ink=3 parts by weight, and the far-infrared emitting agent=1 part by weight. Since the far-infrared heating layer 11 is formed by mixing the conductive ink and the far-infrared emitting agent, and the conductive ink and the far-infrared emitting agen...

Embodiment 2

[0056] Such as figure 1 with figure 2 Commonly shown, a kind of flexible far-infrared heating film, its structure is basically the same as embodiment one, difference is: far-infrared heating layer 11 is mixed by conductive ink and far-infrared emission agent, and far-infrared emission agent is carbon crystal , wherein conductive ink=4 parts by weight, far-infrared emitter=2 parts by weight.

[0057] The preparation method of the above-mentioned flexible far-infrared heating film, its steps are basically the same as in Example 1, the difference is: the conductive ink in step 1) is mixed with the far-infrared emitting agent according to the ratio of 4:2 parts by weight, and stirred to form a liquid mixture spare.

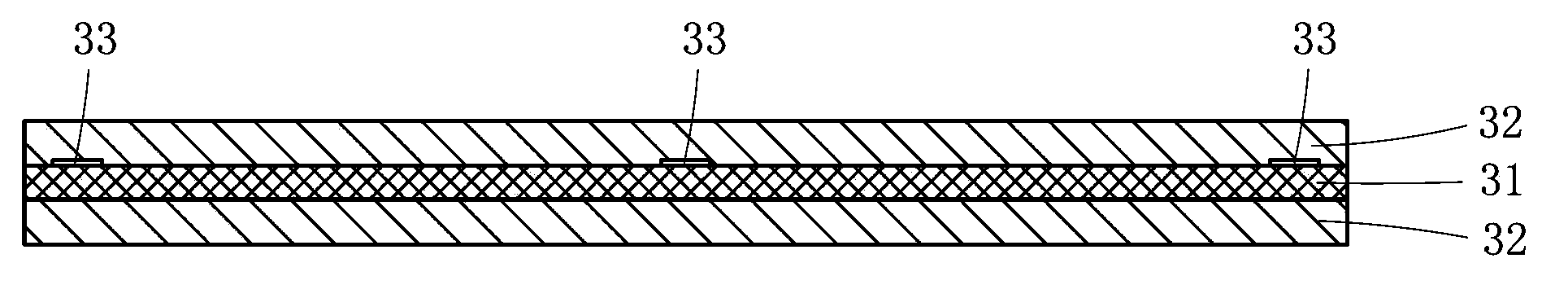

[0058] Such as image 3 , Figure 4 with Figure 5 Commonly shown, a kind of far-infrared carpet that is made by above-mentioned far-infrared heating film, its structure is basically identical with embodiment one, difference is: the far-infrared heating film 31 ...

Embodiment 3

[0060] Such as figure 1 with figure 2 Commonly shown, a kind of flexible far-infrared heating film, its structure is basically the same as embodiment one, difference is: far-infrared heating layer 11 is mixed by conductive ink and far-infrared emission agent, and far-infrared emission agent is carbon crystal , wherein conductive ink=5 parts by weight, far-infrared emitter=3 parts by weight.

[0061] The preparation method of the above-mentioned flexible far-infrared heating film, its steps are basically the same as in Example 1, the difference is: the conductive ink in step 1) is mixed with the far-infrared emitting agent according to the ratio of 5:3 parts by weight, and stirred to form a liquid mixture spare.

[0062] Such as image 3 , Figure 4 with Figure 5 Commonly shown, a kind of far-infrared blanket that is made by above-mentioned far-infrared heating film, its structure is basically the same as embodiment one, and difference is: the far-infrared heating film 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com