Method for testing anti-interference ability of epoxy resin reinforcement of double-layer beam test piece

An epoxy resin, double-layer technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, can solve the problem of no evaluation of reinforcement effect, and achieve accurate evaluation of reinforcement effect, strong operability, and simple and easy method. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

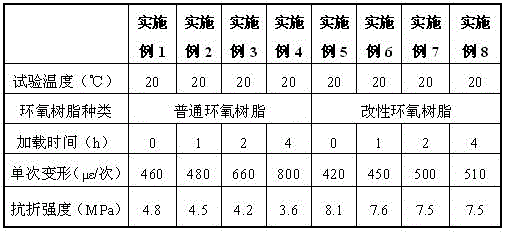

[0020] Example 1 An anti-interference method for testing epoxy resin-reinforced double-layer beam specimens includes the following steps:

[0021] ⑴The double-layer beam of 200mm×50mm×25mm is used to simulate the hollow slab girder of the bridge, and it is reinforced with ordinary epoxy resin to simulate the glue injection reinforcement of the hinge joint of the hollow slab bridge.

[0022] Among them: ordinary epoxy resin refers to a resin that does not change in viscosity within 40 to 60 minutes and cures quickly in 60 to 120 minutes.

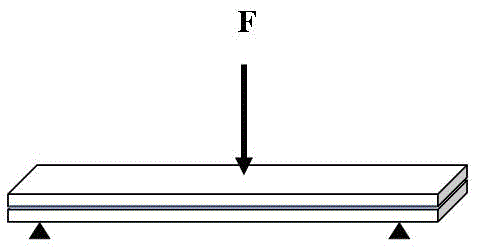

[0023] ⑵After curing for 24 hours, the UTM universal testing machine is used to carry out repeated loading to simulate the dynamic load of driving during the process of joint glue injection reinforcement of the hollow slab bridge (such as figure 1 Shown).

[0024] Among them: the loading condition means that the temperature of the temperature control box is 20 degrees Celsius, the loading stress is 20KPa, the loading frequency is 1Hz, the loading is...

Embodiment 2

[0026] Example 2 An anti-interference method for testing epoxy resin reinforced double-layer beam specimens includes the following steps:

[0027] ⑴The double-layer beam of 200mm×50mm×25mm is used to simulate the hollow slab girder of the bridge, and it is reinforced with ordinary epoxy resin to simulate the glue injection reinforcement of the hinge joint of the hollow slab bridge.

[0028] Among them: ordinary epoxy resin refers to a resin that does not change in viscosity within 40 to 60 minutes and cures quickly in 60 to 120 minutes.

[0029] ⑵After adding ordinary epoxy resin, immediately use UTM universal testing machine for repeated loading to simulate the dynamic load of the vehicle during the process of joint glue injection reinforcement of the hollow slab bridge (such as figure 1 Shown). The interference time is 1 hour, then stop. After the resin is cured to 24 hours, the load is repeated on the UTM universal testing machine.

[0030] Among them: the loading condition means...

Embodiment 3

[0032] Example 3 An anti-interference method for testing epoxy resin-reinforced double-layer beam specimens includes the following steps:

[0033] ⑴The double-layer beam of 200mm×50mm×25mm is used to simulate the hollow slab girder of the bridge, and it is reinforced with ordinary epoxy resin to simulate the glue injection reinforcement of the hinge joint of the hollow slab bridge.

[0034] Among them: ordinary epoxy resin refers to a resin that does not change in viscosity within 40 to 60 minutes and cures quickly in 60 to 120 minutes.

[0035] ⑵After adding ordinary epoxy resin, immediately use UTM universal testing machine for repeated loading to simulate the dynamic load of the vehicle during the process of joint glue injection reinforcement of the hollow slab bridge (such as figure 1 Shown). The interference time is 2 hours, then stop. After the resin is cured for 24 hours, the load is repeated on the UTM universal testing machine.

[0036] Among them: the loading condition mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com