Natural gas hydrate stratum internal reinforcement evaluation device and method

A technology for evaluating devices and hydrates, applied in measurement devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

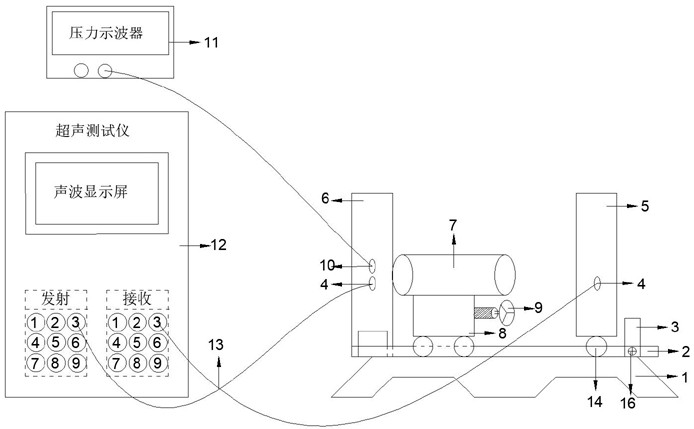

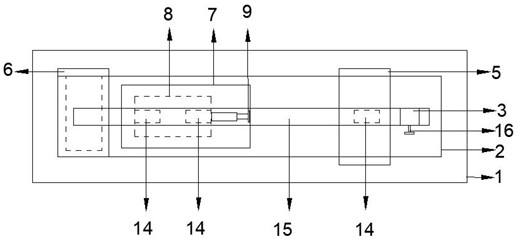

[0031] An intra-layer reinforcement evaluation device for natural gas hydrate formations, the device includes a core support module, an ultrasonic testing module and a pressure monitoring module.

[0032] The core holding module includes a base, a rock core sample placement table, a core splint and a splint holder; a guide rail is provided on the base, and a guide rail groove is provided in the guide rail; the rock core sample placement table is slidingly connected to the guide rail groove ; The core splint includes a left splint and a right splint, the left splint is fixed on the base, the left splint is provided with a pressure oscilloscope probe placement hole and a transducer probe placement hole, the right splint is slidingly connected with the guide rail groove, and there is a switch on it. There is a hole for placing the energy probe; one side of the right splint is provided with a splint fixer, and the splint fixer is provided with a positioning device, and the splint f...

Embodiment 2

[0039]The intra-layer reinforcement evaluation method of natural gas hydrate formations adopts the intra-layer reinforcement evaluation device of natural gas hydrate formations described in Example 1, conducts ultrasonic velocity tests on the formations before and after curing, and establishes the correlation between formation characteristics, ultrasonic frequency and ultrasonic wave velocity , the specific steps are:

[0040] (1) Turn on the power of the ultrasonic tester, place one end of a group of transducers on the transmitting group column and the receiving group column respectively, and place the other ends on the transducer probe placement holes on the left splint and right splint respectively, fix and apply Vaseline, while placing the pressure oscilloscope probe on the left splint;

[0041] (2) According to the shape of the core sample, select the top of the core sample placement platform suitable for stabilizing the core sample, place the core sample in the middle of...

Embodiment 3

[0048] (1) Use the silty clay 5m below the ground in the Jinshatan area of Qingdao as the solidification object, air-dry it naturally, and then dry it in an oven at 60°C, grind and sieve, and retain 50-80 mesh particles as the soil for the experiment;

[0049] (2) The mass ratio of each component of the weakly cemented natural gas hydrate reservoir skeleton is: Jinshatan soil 4000g, experimental soil 1000g, water 800ml. Stir and mix evenly, pour into the core mold, apply a certain pressure, and prepare the rock samples of the experimental group and the control group;

[0050] (3) Take out the rock sample, place it in an oven, and take it out after drying;

[0051] (4) Put the rock sample in the natural gas hydrate triaxial reactor, and control the hydrate saturation by quantifying water and excess methane gas to form a 500mm high natural gas hydrate rock sample;

[0052] (5) The rock core of the control group is subjected to the ultrasonic test described in Example 2;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com