A kind of silver/metal oxide porous material, its preparation method and application

A technology of porous materials and oxides, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of ORR activity gap and achieve low production cost, oxygen The effect of high catalytic activity and easy implementation of reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

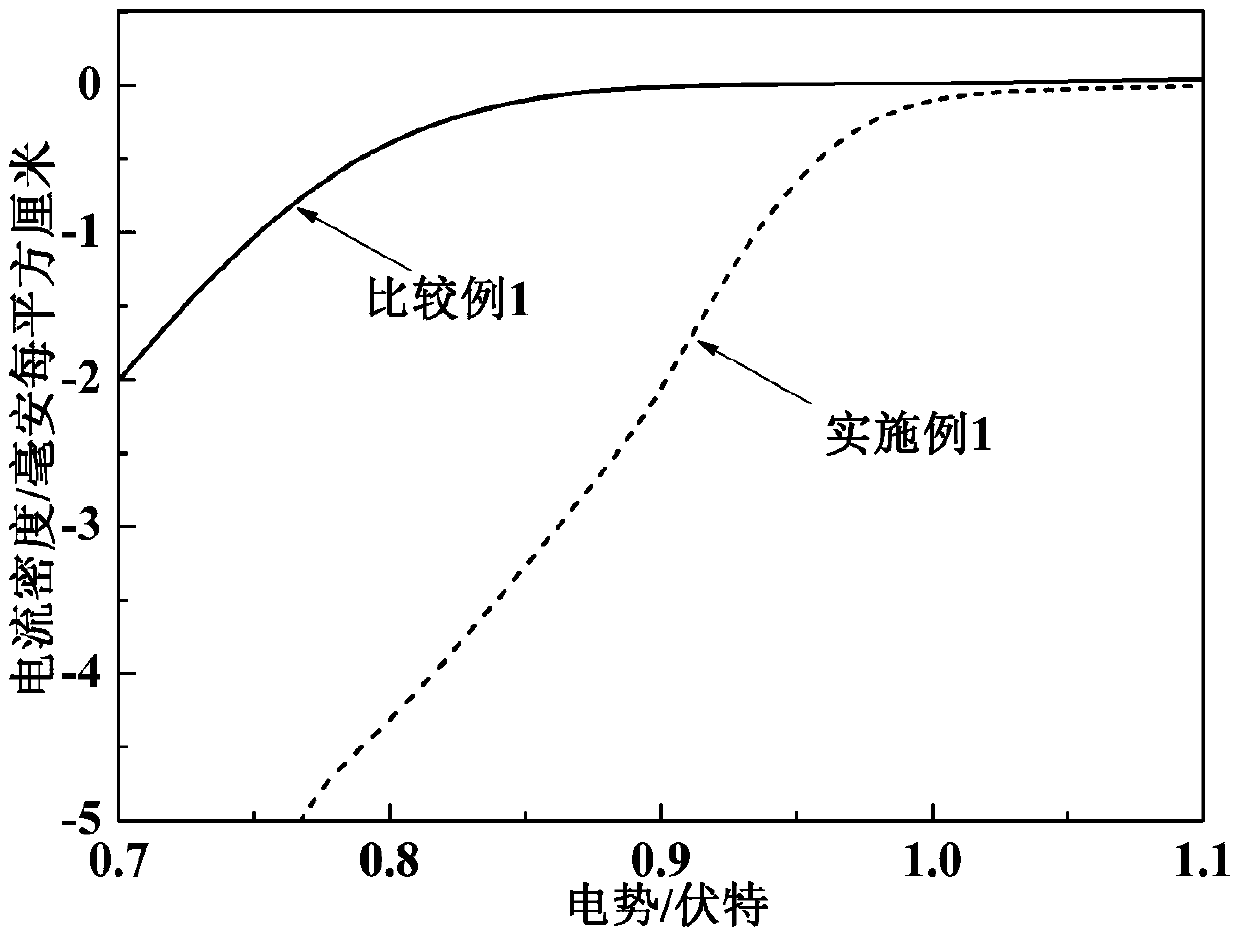

Embodiment 1

[0024] Embodiment 1: configuration contains the solution of 0.005M NaCl and 0.1M NaOH and it is used as electrolytic solution, and the silver lump electrode that diameter is 5mm is as working electrode, and platinum sheet is counter electrode, and mercury / mercuric oxide electrode is reference electrode, Electrochemical treatment at 1.0V (relative to the reversible hydrogen electrode) for 2h followed by electrochemical reduction in 0.1M NaOH electrolyte at 0.15V (relative to the reversible hydrogen electrode) for 5min to obtain porous silver. Prepare a solution containing 50mM manganese nitrate and use it as an electrolyte, porous silver as a working electrode, a platinum sheet as a counter electrode, and a silver / silver chloride electrode as a reference electrode for electrochemical deposition to obtain MnO X / Ag sample.

Embodiment 2

[0025] Embodiment 2: configuration contains the solution of 0.001mM NaCl and it is used as electrolyte, with silver sheet as working electrode, graphite rod is counter electrode, and silver / silver chloride electrode is reference electrode, at 1.5V (relative to reversible hydrogen electrode) under electrochemical treatment for 100 h, and then irradiated under strong light of 200,000 lux for 1 h to obtain porous silver. Prepare a solution containing 50mM copper nitrate and use it as an electrolyte, porous silver as a working electrode, a platinum sheet as a counter electrode, and a silver / silver chloride electrode as a reference electrode for electrochemical deposition to obtain CuO X / Ag sample.

Embodiment 3

[0026] Embodiment 3: configure the solution containing 2M NaCl and 0.1M HCl and use it as electrolyte, use silver rod as working electrode, silver sheet as counter electrode, saturated calomel electrode as reference electrode, electrochemical treatment at 5.0V After 360s, copper target X-rays were irradiated for 1h to obtain porous silver. Prepare a solution containing 50mM ferric nitrate and use it as an electrolyte, porous silver as a working electrode, a platinum sheet as a counter electrode, and a silver / silver chloride electrode as a reference electrode for electrochemical deposition to obtain FeO X / Ag sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com