Manufacturing method of double-tank building safety net cleaning equipment

A technology for cleaning equipment and manufacturing methods, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problem of affecting the construction appearance of construction projects, poor cleaning effects, and shortened safety The service life of the net and other issues can be reduced to achieve the effects of reducing human labor, high work efficiency, and convenient collection and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

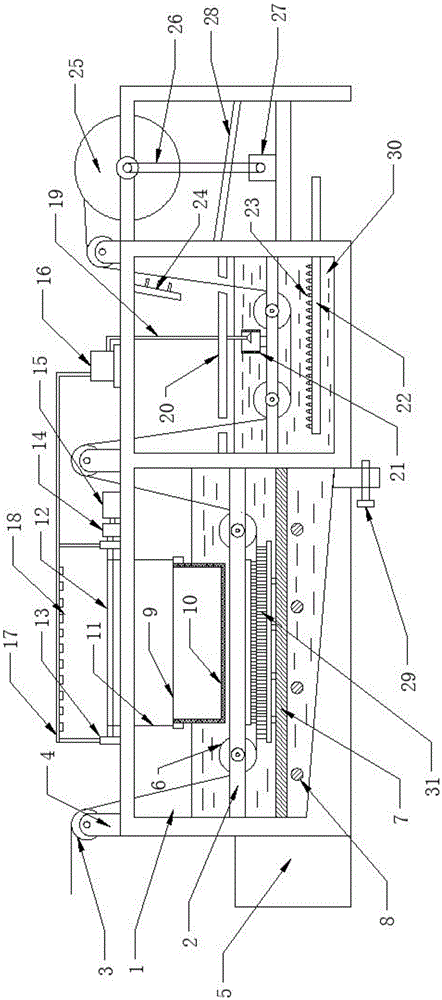

[0024] Example 1: See figure 1 , a double-trough type building safety net cleaning equipment, comprising a cabinet 1, a cleaning tank 9, a clean water tank 21, a flushing tank 30 and an ultrasonic generator 5, the flushing tank 30 is fixedly installed near the cabinet 1, and inside the cabinet 1 and the flushing tank 30 Both are equipped with a fixed beam 2, a symmetrical tension wheel 6 is installed on the fixed beam 2, an ultrasonic generator 5 is fixedly installed on one side of the chassis 1, and a plurality of longitudinal vibration columns 7 and The transverse vibrating column 8 and the longitudinal vibrating column 7 are arranged between the transverse vibrating column 8 and the fixed beam 2, and the longitudinal vibrating column 7 and the transverse vibrating column 8 are evenly staggered, and through the action of the ultrasonic generator 5 and the vibrating column, the safety Dust, dirt and other objects that are difficult to clean on the net are separated; correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com