Balance pushing-pressing device for buried garbage compression equipment

A technology of garbage compressing and pushing device, which is applied to punching machines, presses, manufacturing tools, etc., can solve the problems of lengthening the civil construction of garbage compressors and garbage stations, and increasing the stroke of oil cylinders, so as to save materials and space, shorten the The effect of pressing stroke and reducing the volume of the middle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

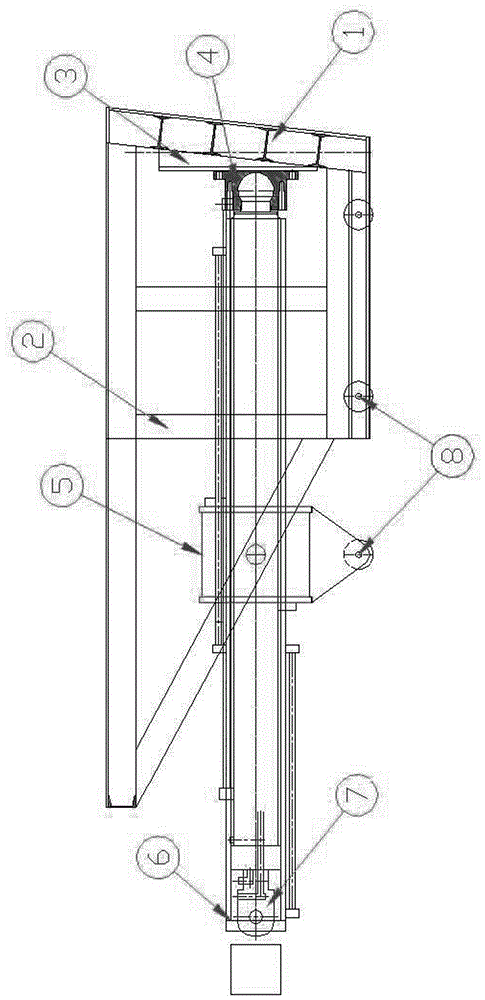

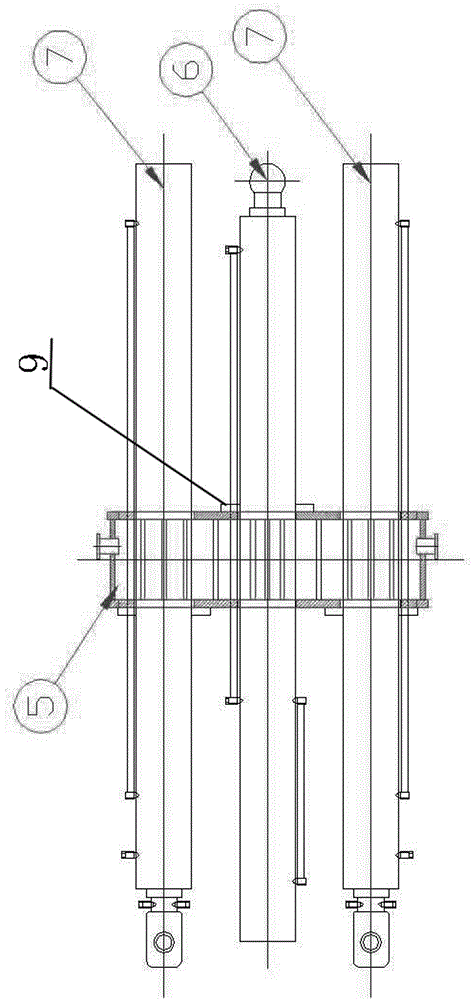

[0012] Further description will be made below in conjunction with the accompanying drawings.

[0013] figure 1 , 2 As shown, the balance pushing device of the buried garbage compression equipment includes a pushing plate 1, a pushing frame 2, a front connecting plate 3, an oil cylinder fixing flange 4, a balance weight 5, a main oil cylinder 6, an auxiliary oil cylinder 7, and a pushing device Traveling gear 8, balance weight 9, oil cylinder flange 10.

[0014] The pusher plate 1 is welded to the pusher frame 2, and the bottom of the pusher frame 2 is provided with a pusher device walking mechanism 8 that is convenient for pushing the material. The end is connected to the front connecting plate 3 through the fixed flange 4 of the oil cylinder, and the two auxiliary oil cylinders 7 are arranged parallel and symmetrically on both sides of the pushing oil cylinder 6, and the three oil cylinders are equipped with oil cylinder flanges 9, and the three oil cylinders pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com