Mini-type reel fixing device

A technology of fixing device and reel, which is applied in the field of devices for tensioning materials, and achieves the effects of light weight, simple assembly and small bearing capacity requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

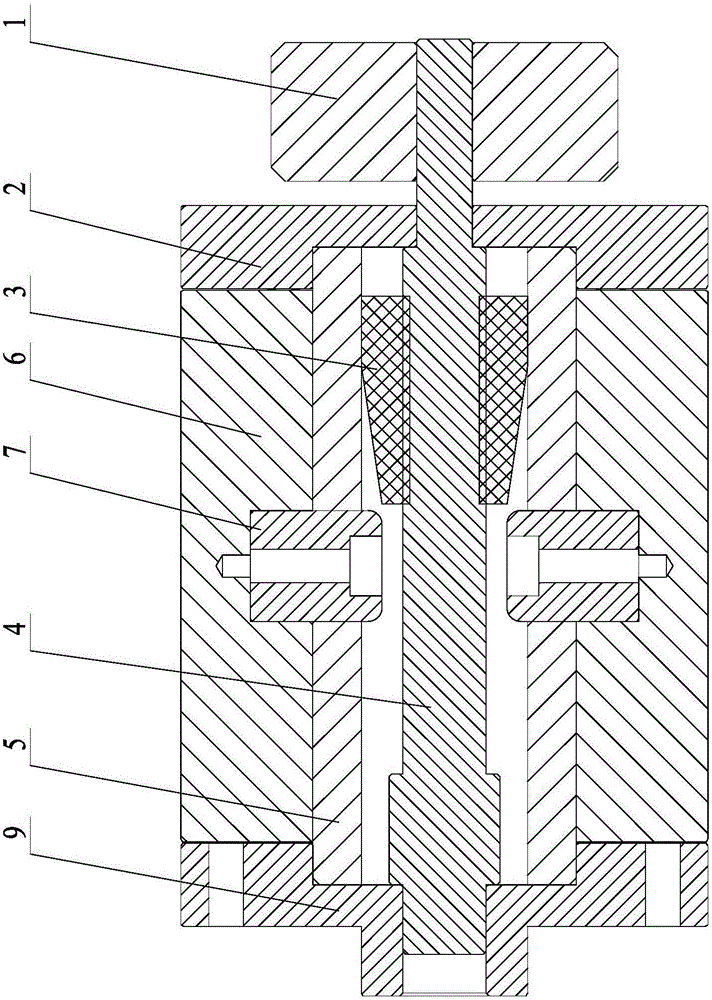

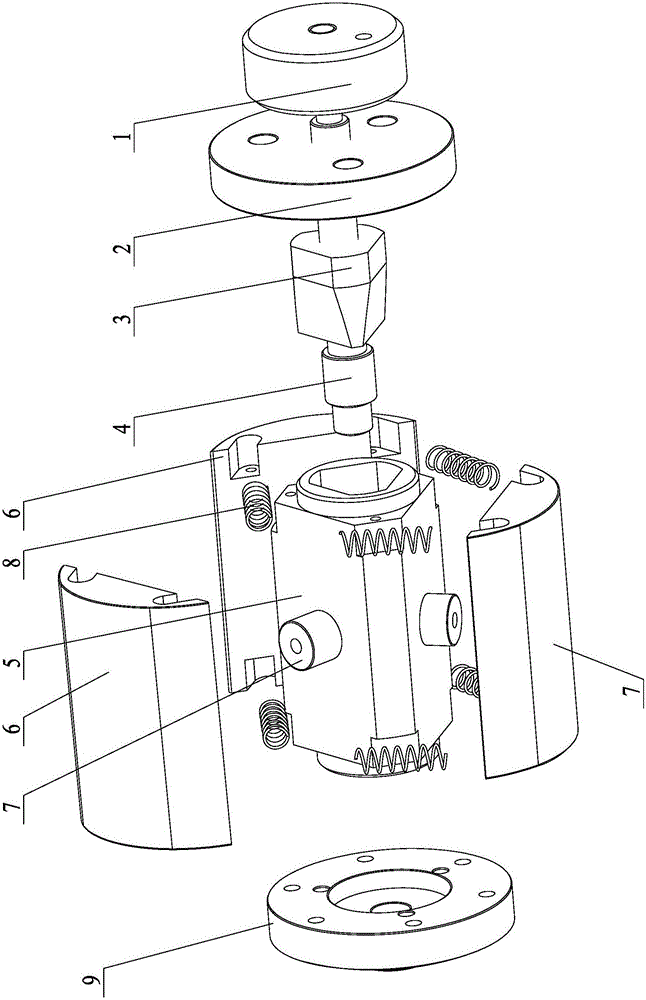

[0015] The miniature reel fixing device includes an adjustment wheel 1, a right end cover 2, an oblique nut 3, an adjustment rod 4, a mandrel 5, a tension block 6, an ejection column 7, a tension spring 8 and a left end cover 9; The mandrel 5 is a polygonal prism in section, and a tension block 6 is attached to each side wall of the mandrel. The outer surface of the tension block 6 is arc-shaped, and the two ends of all the tension blocks 6 are pulled Tight springs 8 are connected in pairs, the sum of the center angles corresponding to the arcs on the outer surface of the tension block 6 is 360°, each side wall of the mandrel 5 is provided with a guide hole for the ejection column, and one end of the ejection column 7 The part is fixed with the tension block 6, and the other end of the ejector column 7 is inserted into the ejector column guide hole of the mandrel 5, and a pris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com