A Plunger Type Fuel Injection Pump with Multiple Working Conditions and Variable Fuel Supply

A plunger-type, multi-working-condition technology, applied to fuel injection pumps, fuel injection devices, engine components, etc., can solve the problem of inability to realize variable adjustment of plunger effective stroke, fixed pump oil frequency, and inability to realize variable fuel supply and other problems, to achieve the effect of convenient linear adjustment and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

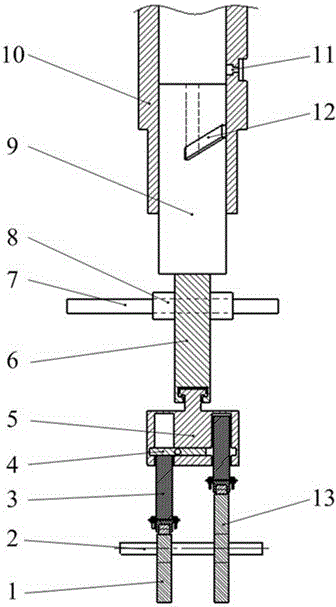

[0038] Such as figure 1 As shown, a plunger-type fuel injection pump with multi-working conditions and variable oil supply of the present invention mainly includes a plunger pair consisting of a plunger 9 and a plunger sleeve 10, and a rack 7, a gear 8 and a rotating shaft 6 The oil volume adjustment device composed of the driving frame 5, the top plate 4 and the top plate lever 19 is the driving selection device, the driving auxiliary device is composed of the guide plate 3, the roller frame 21 and the roller 20, and the driving shaft 2, the low-speed cam 1 and the The two-speed cam driving device that high-speed cam 13 forms.

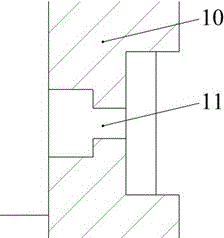

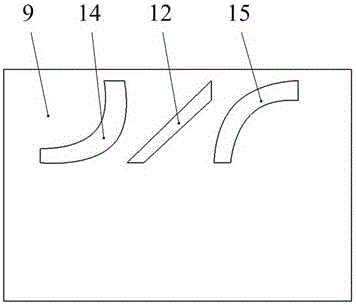

[0039] to combine figure 2 As shown, there is an oil hole 11 on the plunger sleeve 10, and the cross section of the oil hole 11 is a trapezoidal structure with a large inside and a small outside. The sudden trapezoidal structure of the fuel oil not only makes the fuel flow unobstructed when it enters the fuel injection pump, but also generates nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com