Headland Operation Control System

An operation control and headland technology, applied in the direction of control/adjustment system, manual control mechanism, control mechanism, etc., can solve problems such as operator fatigue, tool damage stress, unintentional failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

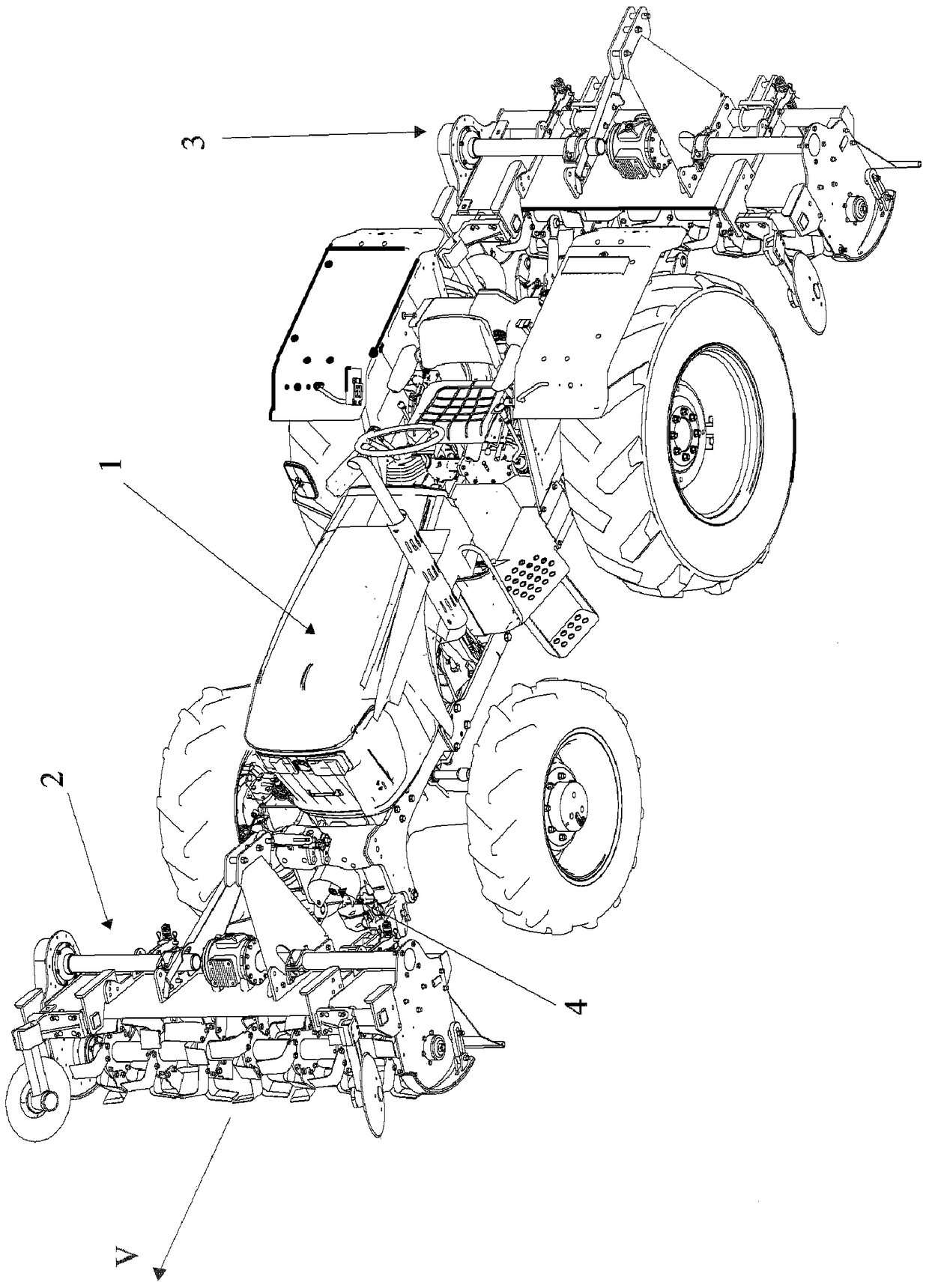

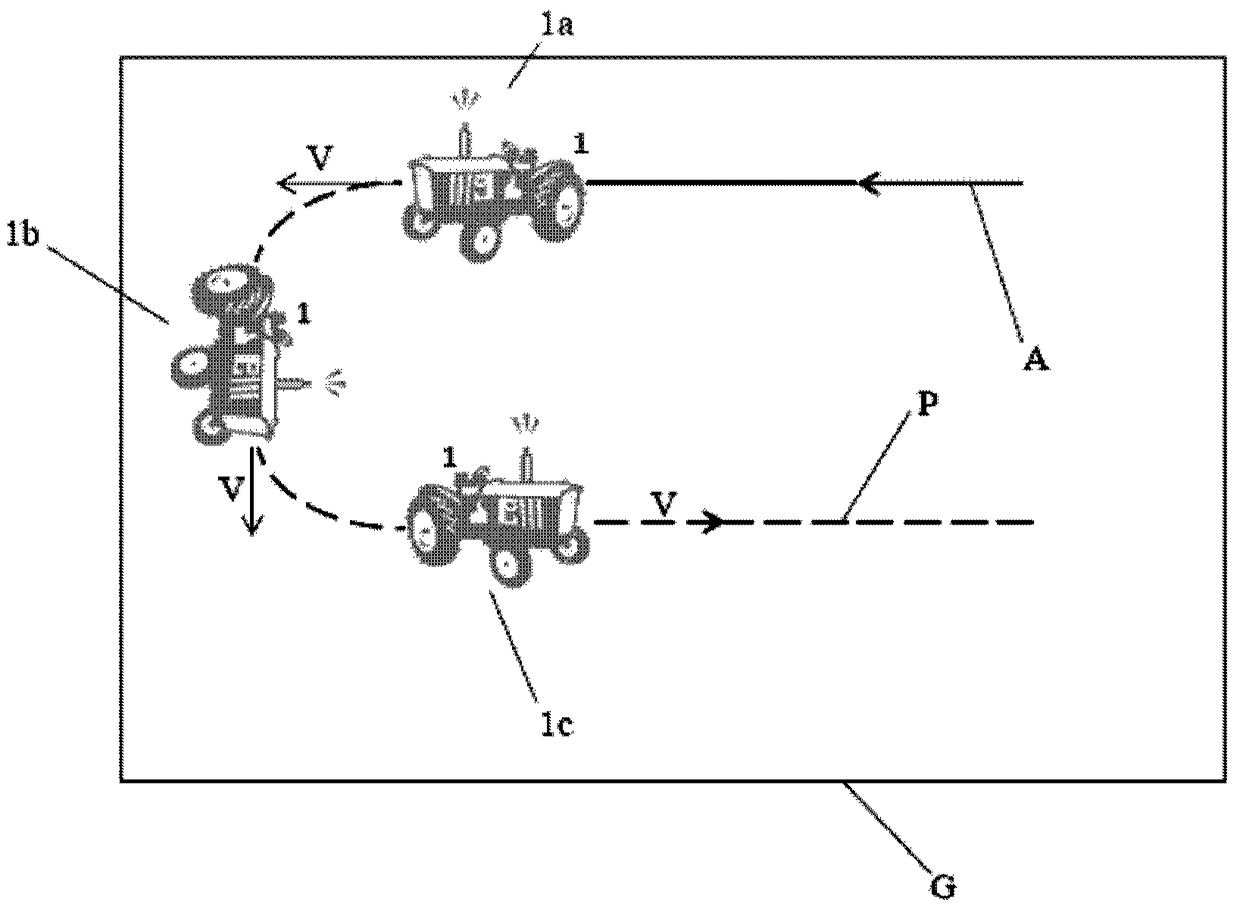

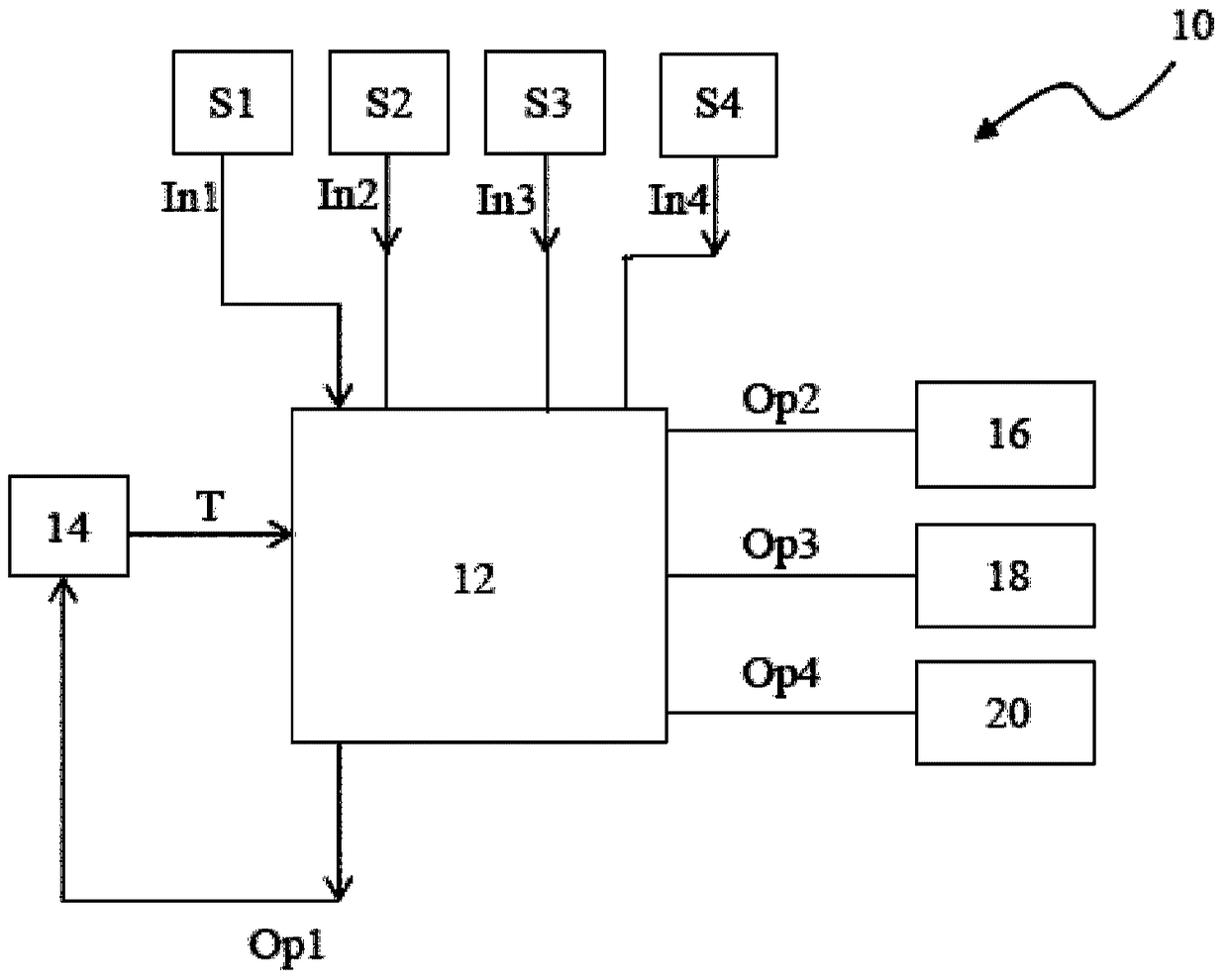

[0028] Vehicles, especially work vehicles such as tractors, need to maneuver around headlands. This requires the operator of the vehicle to perform several operations simultaneously, such as disengaging power to the power take-off (PTO) shaft, disengaging the four-wheel drive, and raising the implement through the tractor's lift arm. Operating multiple mechanisms simultaneously causes operator stress and fatigue. The present invention contemplates operating a single system to operate multiple mechanisms of the vehicle. The headland operation control system of the present invention can be retrofitted to the existing system of the vehicle.

[0029] Embodiments herein and their various features and advantageous details are described with reference to the non-limiting examples described hereinafter. Descriptions of well-known components and processing techniques are omitted so as not to unnecessarily obscure the embodiments herein.

[0030] see figure 1 , the tractor 1 is illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com