Rope traction robot applied to transportation and assembly of space materials

A technology of robots and traction mechanisms, applied in transportation and packaging, aerospace vehicles, manipulators, etc., can solve the problems of limited transfer distance and low transportation efficiency, and achieve the effect of small construction difficulty, fast moving speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

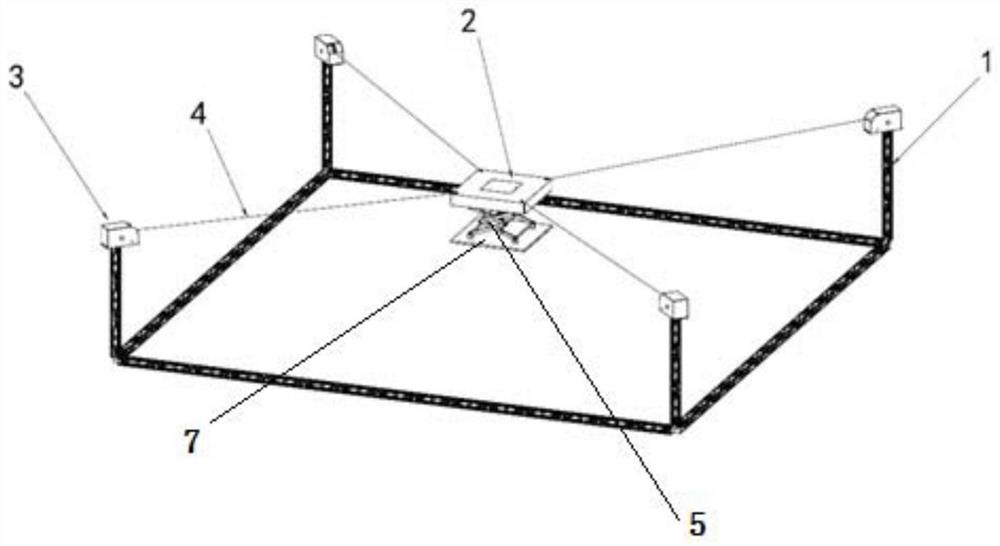

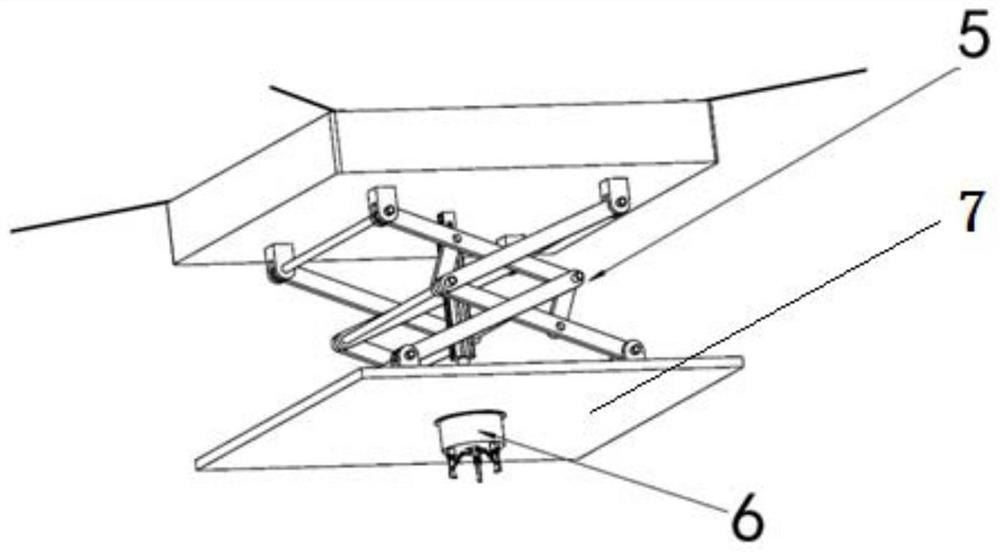

[0013] Specific implementation mode one: combine Figure 1 to Figure 2 Describe this embodiment. A rope traction robot applied to the transportation and assembly of space materials in this embodiment includes a support structure 1, a mobile base 2, a plurality of traction mechanisms 3, a plurality of traction ropes 4, a lifting mechanism 5, and a docking and clamping mechanism. The mechanism 6 and the bottom plate 7, the support structure 1 is a frame structure, the support structure 1 is arranged in the space of weightlessness in space, a traction mechanism 3 is installed at least three points on the support structure 1 that are not located on the same straight line, and each traction rope One end of 4 is connected to a traction mechanism 3, and the other end of each traction rope 4 is connected to the mobile base 2 located in the middle of the support structure 1. Multiple traction ropes 4 drive the mobile base 2 to move under the action of the traction mechanism 3, and the l...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 To describe this embodiment, the traction rope 4 of this embodiment is a steel wire rope or a cable with a conductive function. Such setting facilitates power transmission for the robot base and other equipment through the traction rope 4 . Other compositions and connections are the same as in the first embodiment.

[0018] The traction rope 4 of this embodiment can realize power transmission between the robot base 2 and the supporting structure 1 .

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1 to Figure 2 Describe this embodiment, this embodiment also includes a docking clamping mechanism 6, the docking clamping mechanism 6 is installed on the lower end surface of the bottom plate 7, and the docking clamping mechanism 6 clamps the assembly robot. So set up to hold robots with precision butt fittings. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com