Dynamic static integrated tobacco leaf selecting system and process

A dynamic and static combination, tobacco leaf technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of reduced selection time, missed inspection, and wrong selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

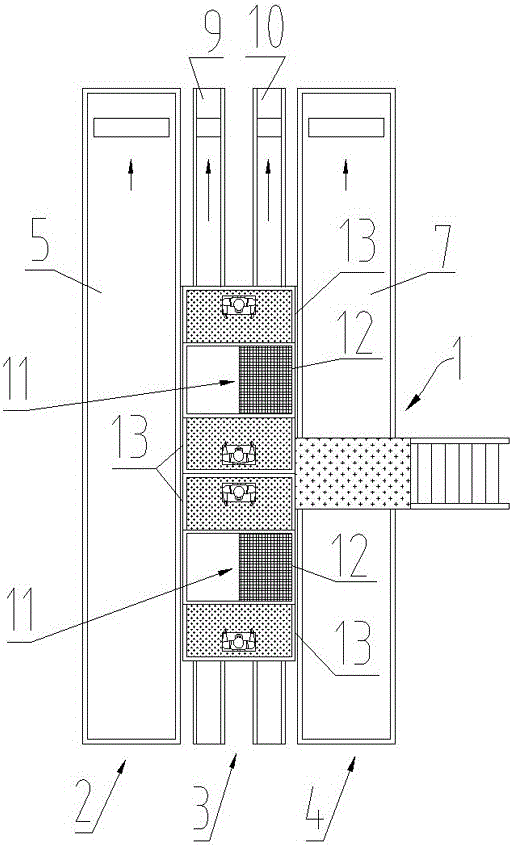

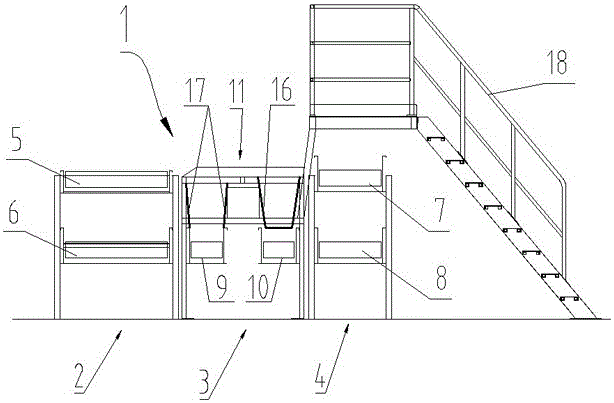

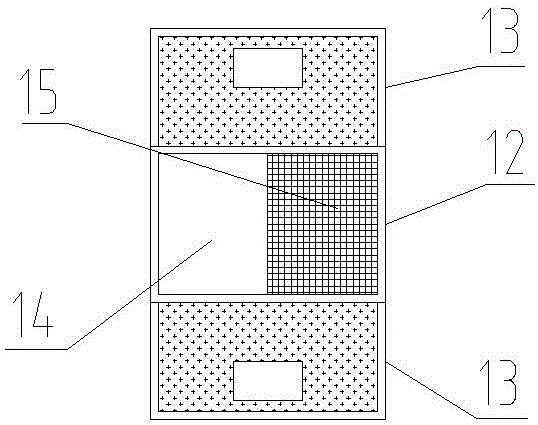

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] Such as Figure 1 to Figure 4 As shown, a combination of dynamic and static tobacco leaf selection system includes multiple groups of picking units 1, and multiple groups of picking units 1 are arranged parallel to each other at a certain distance. The first picking area 2 and the 3rd picking area 4 on both sides of picking area 3 preferably make the first picking area 2 and the third picking area 4 symmetrically arranged on both sides of the second picking area 3, the first picking area 2 Sorting belt conveyor one 5 and sorting belt conveyor two 6 are arranged at intervals up and down, and the third picking area 4 is provided with sorting belt conveyor three 7 and sorting belt conveyor four 8 at intervals up and down, and the second picking area 3 bottom is symmetrically arranged Sorting belt conveyor five 9 and sorting belt conveyor six 10, the upper part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com