Biocorrosion inhibitor for metal

一种生物腐蚀、金属的技术,应用在杀生物剂、杀生剂、用于生物控制的化学品等方向,能够解决发展机制未阐明等问题,达到保存稳定性优越、高度环境和职业安全性、金属生物腐蚀抑制能力优越的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

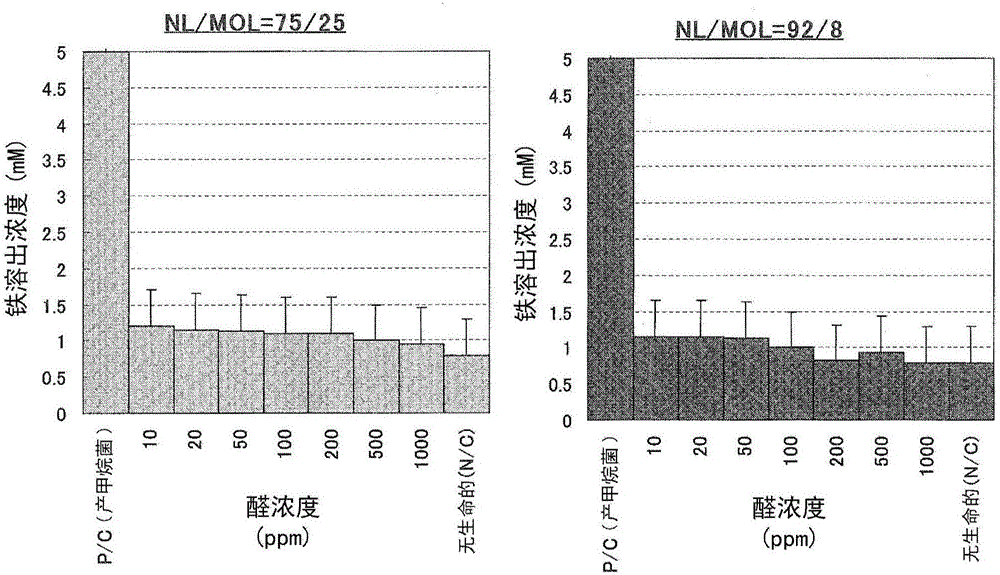

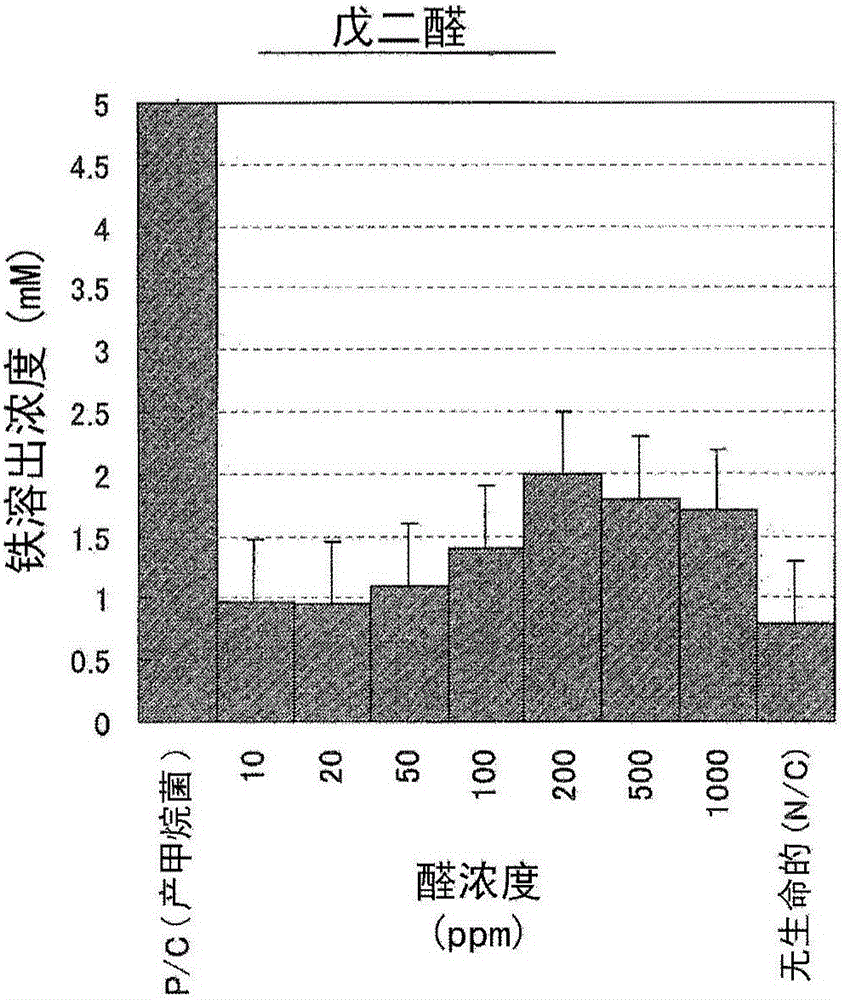

Image

Examples

Embodiment 1

[0070] [Preparation of a mixture of 1,9-nonanedialdehyde (NL) and 2-methyl-1,8-octanedial (MOL)]

[0071] By the method described in JP-B-2857055, a mixture of 1,9-nonanedialdehyde (hereinafter referred to as NL) and 2-methyl-1,8-octanedial (hereinafter referred to as MOL) was prepared. The mass ratio of NL to MOL in the mixture is NL / MOL=85 / 15.

[0072] [Preparation of inorganic salt seawater matrix (solution A)]

[0073] Milli-Q water 970ml, NaCl19.0g, MgCl 2 ·6H 2 O2.6g, CaCl 2 2H 2 O0.15g, Na 2 SO 4 4.0g, NH 4 Cl0.25g, KH 2 PO 4 4.0g, KCl0.5g, HEPES (2-[4-(2-hydroxyethyl)-1-piperazinyl]ethanesulfonic acid) 23.8g are mixed and dissolved in anaerobic chamber, to prepare inorganic salt seawater substrate ( Solution A).

[0074] Milli-Q water is ultrapure water prepared using a device manufactured by Merk Millipore (for example, Milli-Q Integral 10).

[0075] [Preparation of sodium bicarbonate solution (solution C)]

[0076] NaHCO 3 (2.52 g) was dissolved in Mill...

Embodiment 2

[0086] Oral toxicity measurement, toxicity test to algae, sterilization test to sludge and biodegradability test were performed on NL, MOL and glutaraldehyde. The test method and results are shown below.

[0087]

[0088] The test substances were emulsified and dispersed in 2%-gum arabic aqueous solution (containing 0.5%-Tween80) and force-administered to 6-week-old male CRj:CD(SD) rats with an oral gavage needle once a day for 14 sky. Body weight changes and general condition were observed during the administration period. Rats were fasted for one day from the last administration day (free access to drinking water), and dissected, blood samples were collected (various blood tests), and mass measurements of major organs were performed on the day following the last administration. In addition, histopathological examination (HE-stained sheet sections by light microscopy) of liver, kidney, spleen and testis was performed. The dose was 1000, 250, 60, 15 or 0 mg / kg / day (amount...

Embodiment 3

[0133]

[0134] The following test solutions were respectively placed in vial containers, the gas space part was replaced with nitrogen, and tightly sealed, and stored at 60°C. The NL / MOL or glutaraldehyde content of each test solution at the beginning of storage was regarded as 100%, and the content changes after 5 days, 12 days and 21 days were observed by gas chromatography using an internal standard according to the analytical curve method. The results are shown in Table 4.

[0135] Test solution 1: mixture of NL and MOL (mass ratio: 92 / 8)

[0136] Test solution 2: mixture of NL / MOL / water=91:7:2 (mass ratio)

[0137] Test solution 3: 50% glutaraldehyde aqueous solution (supplied by Tokyo Chemical Industry Co., Ltd.)

[0138] [Gas Chromatography Analysis Conditions]

[0139] Analytical instrument: GC-14A (manufactured by Shimadzu Corporation)

[0140] Detector: FID (Flame Ionization Detector)

[0141] Column used: G-300 (length 20m, film thickness 2μm, inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com