Energy-saving light steel movable room

A kind of mobile room, energy-saving technology, applied in the field of mobile room, can solve the problems of poor thermal insulation and ventilation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

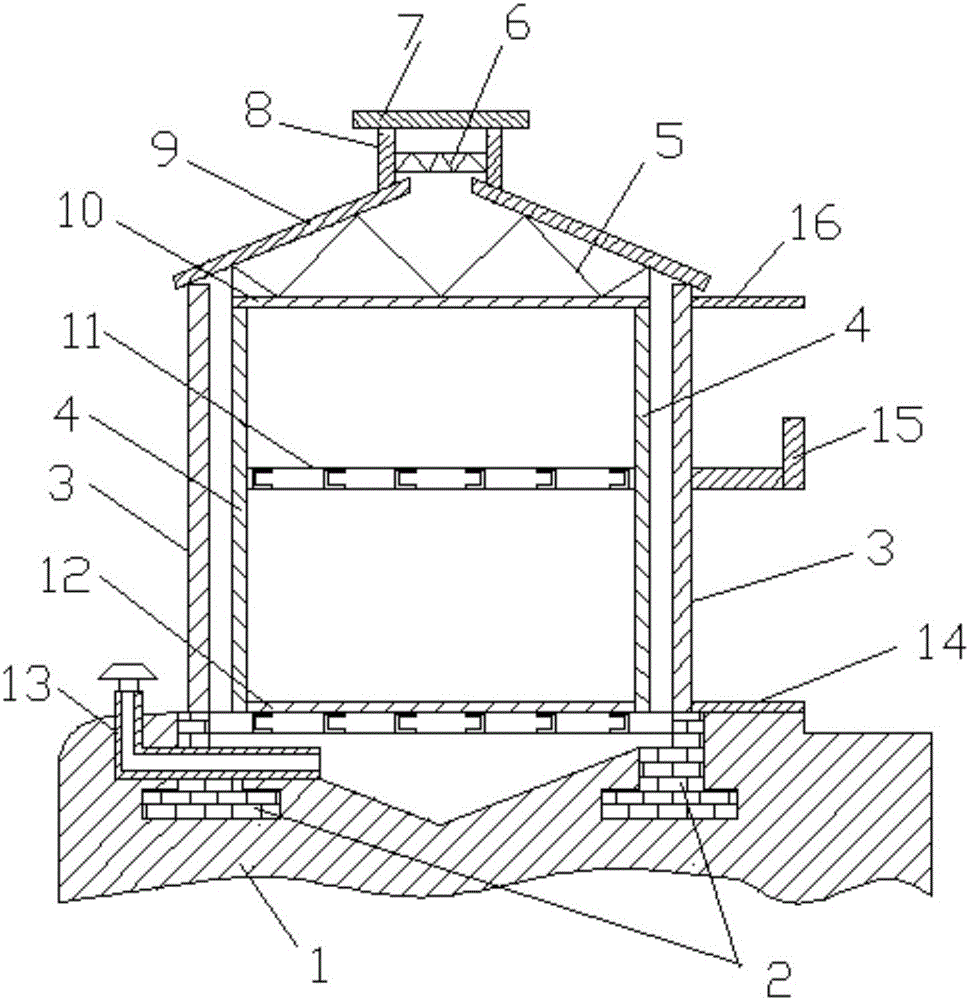

[0023] According to the needs of the house, the color steel plate is used to assemble a large block board. The block board can be made according to the structural size requirements of the house. The 3MM thick steel plate is processed into a 50MM C-shaped steel frame as the frame, and the 5 cm thick mineral wool color steel plate is made into a large block board. Use two boards as the inner board 4 and the outer board 3 respectively, and then assemble them into an outer wall board with an air interlayer. The distance between the inner board 4 and the outer board 3 is 10 to 15 cm. Boards are used to assemble the outer walls of the prefabricated house.

[0024] In order to facilitate disassembly and assembly, large-scale panels are assembled with color steel plates as the inner panel 4 and outer panel 3 respectively. The panels can be made according to the structural size requirements of the house, with 5CM and C-shaped steel as the frame, and 5 cm thick mineral wool color steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com