Improved chimney valve

A flue valve and valve body technology, applied in valve devices, engine components, mechanical equipment, etc., can solve the problems of not meeting actual use requirements, increasing manufacturing costs, and large friction coefficients, achieving enhanced sealing and reduced friction coefficients. , the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

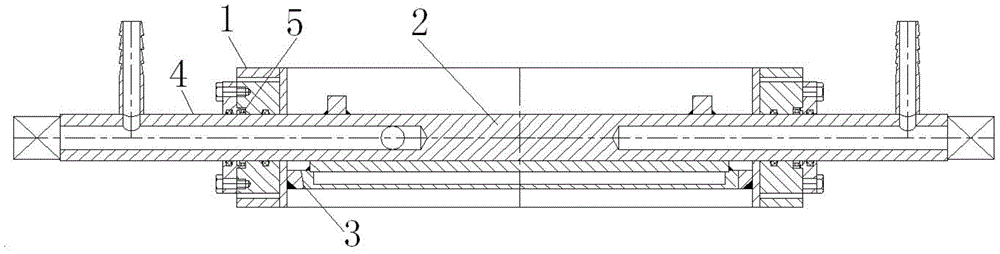

[0009] Such as figure 1 As shown, an improved flue valve according to the present invention includes a valve body 1 and a valve core 2, the valve core 2 is arranged inside the valve body 1, and at the joint A tapered connection edge 3 is provided, and an actuator 4 is arranged on the valve body 1, and the actuator 4 is movably connected with the valve body 1 through a rolling bearing 5; the taper between the tapered connection edge 3 and the vertical direction is within 10 Between -20°. The invention has reasonable structural design, stable and reliable overall operation, and adopts 10-20° conical connection edge to enhance the sealing between the valve body and the valve core, and the air leakage rate is reduced from 20% to 5%, greatly improving The working performance is improved, and the rolling bearing is used to reduce the friction coefficient be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com